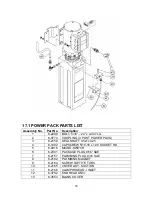

9.1 POWER PACK INSTALLATION

1.

POWER UNIT REQUIREMENTS:

230 volts, single-phase power. Use

separate circuit for each unit and protect each unit with 30 AMP time delay

fuse or circuit breaker.

2. Have a certified electrician wire your pump to the pump motor. The

electrical diagram is provided. (See Figure 7).

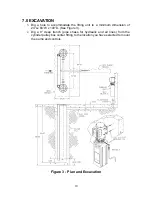

3. Attach pumping unit (tank down) to location selected in front of lift. The

connecting fittings should be at least 36” off the floor.

4. Install the hydraulic lines and air lines through the 1-1/2” PVC.

5.

FILLING PUMPING UNIT:

Fill pumping unit with AW-32 hydraulic oil,

I.S.O. 32 with anti-rust and anti foam agents (approx. 14 quarts). DO NOT

USE TRANSMISSION FLUID.

9.2 HYDRALLIC AND AIR CONNECTIONS

1. Install the 1/2” O. D. x 21’ hydraulic line and the 1/4” O. D. x 21’ airline

from the pump to the pulley box through the 1-1/2” PVC sweep.

2. Connect the hydraulic line to the tee and the air line to the air cylinder

elbow fitting, both located inside the pulley box.

3. Connect the other ends to the pumping unit hydraulic fitting and air lift lock

release button (safety release valve) making sure that all fittings are

properly tightened. (See Figure 5).

4. Run an air supply line from shop air to the 1/8” pipe fitting at the base of

the air lock release button on pump.

16

Summary of Contents for 40HP210ES

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

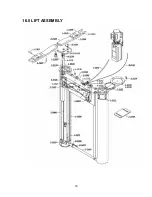

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...