10.0 BLEEDING PROCEDURES

After filling the unit, there will still be trapped air in the system. You must bleed

the system as instructed for proper operation of lift.

1. To bleed the air from the hydraulic system, raise the internal cylinders

approximately 12”, using the pumping unit. (LIFTING STRUCTURES

MUST BE OFF).

2. Loosen the 1/4” hex head bolt at the end of each internal cylinder, using a

7/16” socket wrench. (DO NOT ALLOW THE INTERNAL CYLINDER TO

ROTATE WHILE LOOSENING OR TIGHTENING THIS PLUG).

3. Step down on the end of each cylinder to force the trapped air from the

system. Repeat if necessary to remove all air till oil begins to flow from the

plug.

4. Once this is completed make sure to properly apply sealant to these plugs

and tighten to prevent leaking.

5. Open lowering valve on pump. Step on the ends of these cylinders to

force them back down.

6. Add oil till recommended level in the tank is met.

7. Attach the arm structures. Torque 7/8” bolster bolts to 250 lbf-ft.

8. Raise lift fully and wipe pistons down with a light coat of silicone lubricant

or WD-40.

9. Lower the lift and record oil level in the pumping unit.

10. Pressure check bleed-plugs by inspecting them through the hole in the

center of the lifting structures.

11. Check the hydraulic tee and the fitting on the pump for any leaks, tighten

if necessary.

CAUTION!

DO NOT FULLY RAISE LIFT WITHOUT SUPERSTRUCTURES

ATTACHED. THE PISTONS WILL COME OUT OF CASINGS AND

MAY BE DIFFICULT TO LOWER WITHOUT THE WEIGHT OF THE

SUPERSTRUCTURE ON THEM.

WHEN BLEEDING CYLINDERS, DO NOT ALLOW INNER

CYLINDERS TO ROTATE. THIS MAY CAUSE HOSE KINK.

KEEP ALL LIQUIDS AWAY FROM LIFT (water, cleaners, acids,

etc). ANY LIQUID WHICH GETS INSIDE THE LIFTING UNIT WILL

CAUSE INTERNAL DAMAGE AND WILL NOT BE COVERED

UNDER WHEELTRONIC’S WARRANTY.

17

Summary of Contents for 40HP210ES

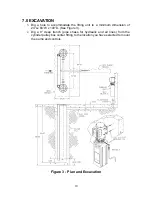

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

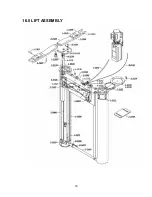

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

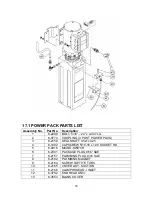

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...