12.0 OPERATING INSTRUCTIONS

It is the responsibility of the Owner/Operator to be thoroughly familiar with the

Operation, Inspection, and Maintenance of this lift.

Before Lifting: DO NOT RAISE CYLINDERS WITHOUT

SUPERSTRUCTURES ATTACHED.

IMPORTANT:

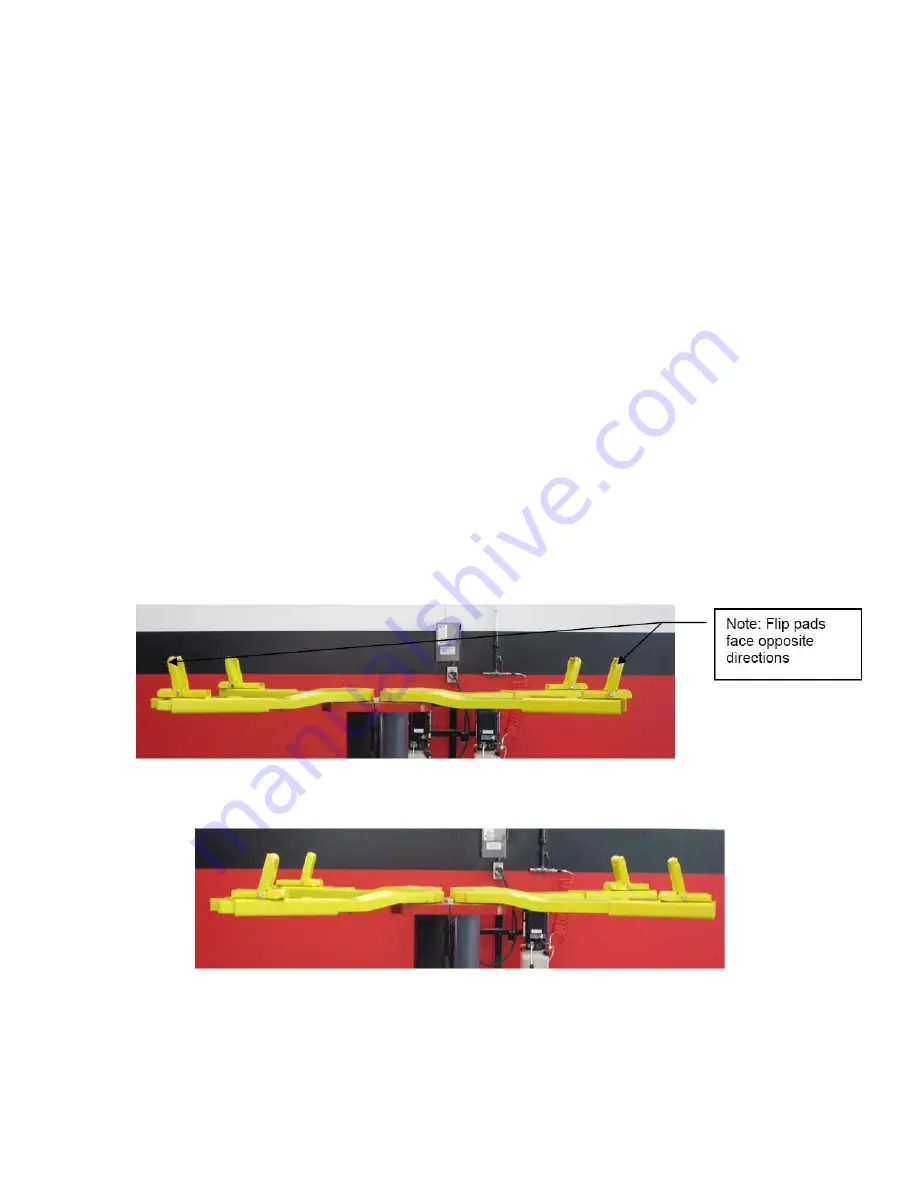

When lifting the vehicle, the flip pad adapters must be

positioned as shown in Figures 7 and 8.

•

ALL FLIP PADS MUST FACE OPPOSITE DIRECTIONS

•

FLIP PADS CANNOT POINT IN THE SAME DIRECTION

1. Rotate arms to provide tire clearance.

2. Center vehicle left and right over lift with wheel in proper spotting plate

according to vehicle size.

3. Position adapter pads at vehicle manufacturer’s approved lifting points.

4. If adapters are raised, face front and rear in opposite directions. Make

sure the height adapters are positioned in a proper designated location.

(See Figures 7 – 9).

Figure 7 - CORRECT positioning of flip pad adapters

Figure 8 - CORRECT positioning of flip pad adapters

19

Summary of Contents for 40HP210ES

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...