13.0 AUTOMOTIVE LIFT SAFETY TIPS

Please post these safety tips in a place where the operator will be constantly

reminded of their importance. ALWAYS REFER TO THE LIFT

MANUFACTURER’S SPECIFIC SAFFTY OPERATION AND MAINTENANCE

INSTRUCTIONS

1. When positioning vehicle, do not hit or run over lift arms, adapters or axle

supports.

2. Operating valves, switches and locking devices are designed for

maximum safety. Never attempt to block open or override them.

3. Never overload your lift beyond manufacturer’s stated capacity.

4. Do not allow customers or bystanders to operate lift or to be in lift area

during operation. Never raise vehicles with anyone inside.

5. Be sure work area around lift is clear, free of obstructions, debris, grease

and oil.

6. Never lift a vehicle unless arm restraints are locked.

7. Never attempt to operate a lift if it appears to be malfunctioning or if

broken/damaged parts are evident.

8. Load lift carefully. Check to be sure adapter or axle supports are in secure

contact with vehicle, PER MANUFACTURER’S INSTRUCTIONS, before

raising to desired working height. NEVER LIFT VEHICLE BY

SUSPENSION PARTS.

9. Release locking devises as per manufacturer’s instructions before

attempting to lower lift.

10. Before removing vehicle from lift area, position arms, adapters or axle

supports to assure that vehicle or lift will not be damaged.

21

Summary of Contents for 40HP210ES

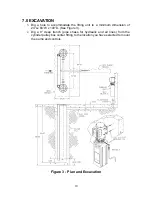

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

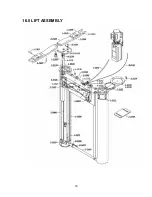

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

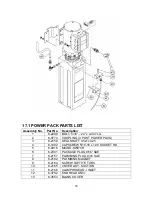

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...