14.0 TROUBLE SHOOTING GUIDE

Possible Cause & Solution

1. Pump motor does not run

A. Breaker tripped or fuse blown. Check breaker and incoming power.

B. Motor thermal overload tripped. Wait for overload to cool.

C. Check thermal overload in starter box (3 phase only). Push reset.

D. Faulty wiring connections. Check wiring diagram.

2. Motor runs but the lift will not rise

A. A foreign object is lodged under check valve. As you are running the

pumping unit, push or hold a load in and out several times on the

lowering valve. This should release any foreign objects trapped in the

pump.

B. Remove check valve. Clean the ball and seat, and replace if

necessary.

C. Oil level low. Check reservoir. With lift in the down position, the pump

reservoir should be full.

3. Motor runs but the lift picks up partial load only

A. Lift is overloaded. Check lifts capacity and weight of vehicle.

B. Relief valve setting is too low. Remove hex head plug in the center of

the pump and adjust pressure setting valve.

4. Oil blows out breather

A. Oil reservoir overfilled.

B. Lift lowered too quickly while under heavy load.

5. Lift makes groaning sound when rising

Bleed cylinder manually. Trapped air can cause groaning noise when

rising or lowering lift.

6. Lift rises unevenly.

A. Cables are not properly adjusted or tightened.

B. Use lightweight oil in the pump. AW-32 hydraulic oil I.S.O. 32 with

antifoam and antirust agents.

22

Summary of Contents for 40HP210ES

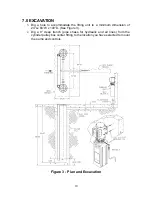

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

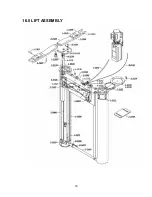

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

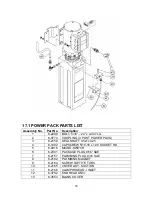

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...