- Page 21 -

EHP Series Operation Instructions

NOTICE!

SOME TIRES HAVE A COLOR DOT THAT IS TO BE KEPT

ON THE OUTSIDE OF THE WHEEL AND IS TO BE ALIGNED

WITH THE VALVE STEM. IF THIS IS THE CASE BE SURE

TO ATTAIN PROPER ALIGNMENT PRIOR TO TIRE INFLA-

TION.

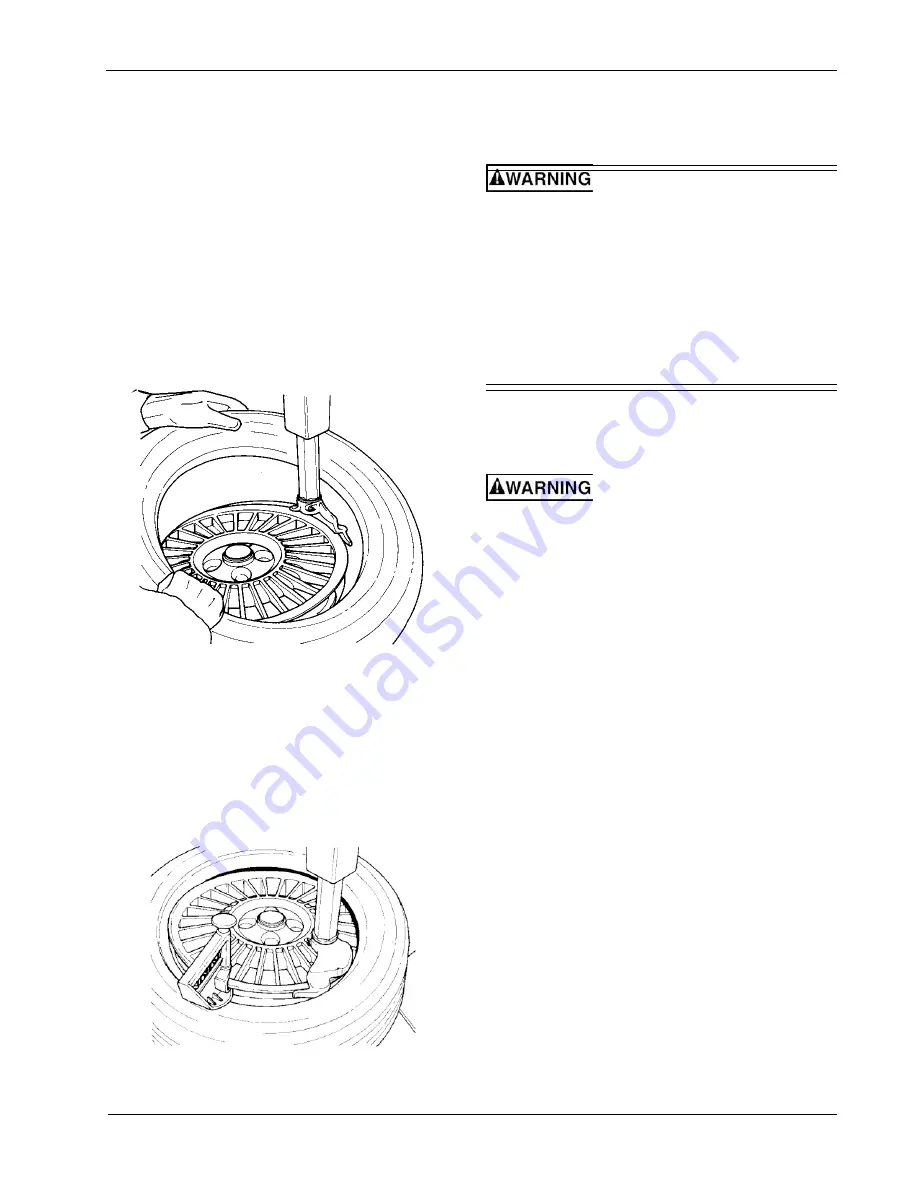

B. Lock the rim to the turntable and rotate it so that the

valve is at the 2 o’clock position. Place the tire to be

mounted on the rim. Swing the mount/demount arm in

so that the mount/demount head is in the working po-

sition. (Fig. 20) Engage the lower bead OVER the

mount/demount head and UNDER the mounting fin-

ger of the mount/demount head (Fig.20). Turn the

wheel clockwise (right pedal down) while simulta-

neously pushing the tire down into the drop center,

opposite to the mount/demount head.

338

Fig.20

C. Mount the upper bead following the directions in sec-

tion B. With low profile tires the bead holding clamp

(option 66735 Fig.21) can help to prevent the top bead

from prematurely seating during the mounting cycle.

NOTE: Bead Holding Clamp must be removed prior to

coming full circle and impacting the mount/demount

head.

39

Fig.21

4.3 INFLATION OF TUBELESS TIRES.

Make sure that both beads are properly lubricated.

BEAD SEATING IS THE MOST DANGEROUS PART OF

MOUNTING A TIRE.

NEVER STAND OVER TIRE WHEN ATTEMPTING TO SEAT

BEADS OR DURING INFLATION

IT IS POSSIBLE TO INCORRECTLY MOUNT TIRES THAT

ARE 1/2" SMALLER IN DIAMETER THAN THE RIM THAT

THEY ARE MOUNTED ON. WHILE THESE BEADS WILL

SEAL, IT IS IMPOSSIBLE TO GET THEM TO SEAT IN

THEIR PROPER POSITION.

EXPLOSION OF A TIRE MAY CAUSE SEVERE INJURY OR

DEATH.

Inflate tire according to manufacturers recommenda-

tions.

SAFETY RESTRAINT ARM MUST BE IN PLACE PRIOR

TO ATTEMPTING BEAD SEATING OR INFLATION.

NEVER EXCEED THE MAXIMUM PRESSURE ALLOWED

BY THE TIRE MANUFACTURER.

THE RIM MUST BE UNCLAMPED WHEN INFLATING BUT

ONLY AFTER THE BEADS HAVE BEEN SEATED.

THE OPERATOR MUST STAND CLEAR FROM THE

WHEEL WHEN INFLATING, AND PRESSURE MUST BE

MONITORED FREQUENTLY TO AVOID OVER INFLATION.

BEFORE INFLATING A TIRE, CHECK THE CONDITION OF

THE TIRE AND THE RIM.

Due to unusual configurations or the stacking of tires

the inflation process may be difficult. To assist with this

problem the JBC EHP Series Tire Changers are

equipped with bead seater jets integrated into the table

top.

To utilize the bead seater proceed as follows:

A. Position the safety restraint arm over center of wheel

assembly. The safety arm is lifted upward by grasping

the safety restraint position knob and lifting upward while

simultaneously depressing the anti-rotation lock arm.

Swing safety arm assembly so the circular retainer is

centered over the rim. Note that air pressure to the

inflation hose will not flow until the arm is centered over

the rim.

B. If possible lock the wheel from inside. Outside lock-

ing reduces efficiency.

For Reference Only

For Current Info See Equiserv.com

Summary of Contents for EHP System I

Page 2: ... BLANK PAGE For Reference Only For Current Info See Equiserv com ...

Page 4: ... BLANK PAGE For Reference Only For Current Info See Equiserv com ...

Page 26: ... BLANK PAGE For Reference Only For Current Info See Equiserv com ...

Page 27: ... BLANK PAGE For Reference Only For Current Info See Equiserv com ...