EN-11

2.0-1

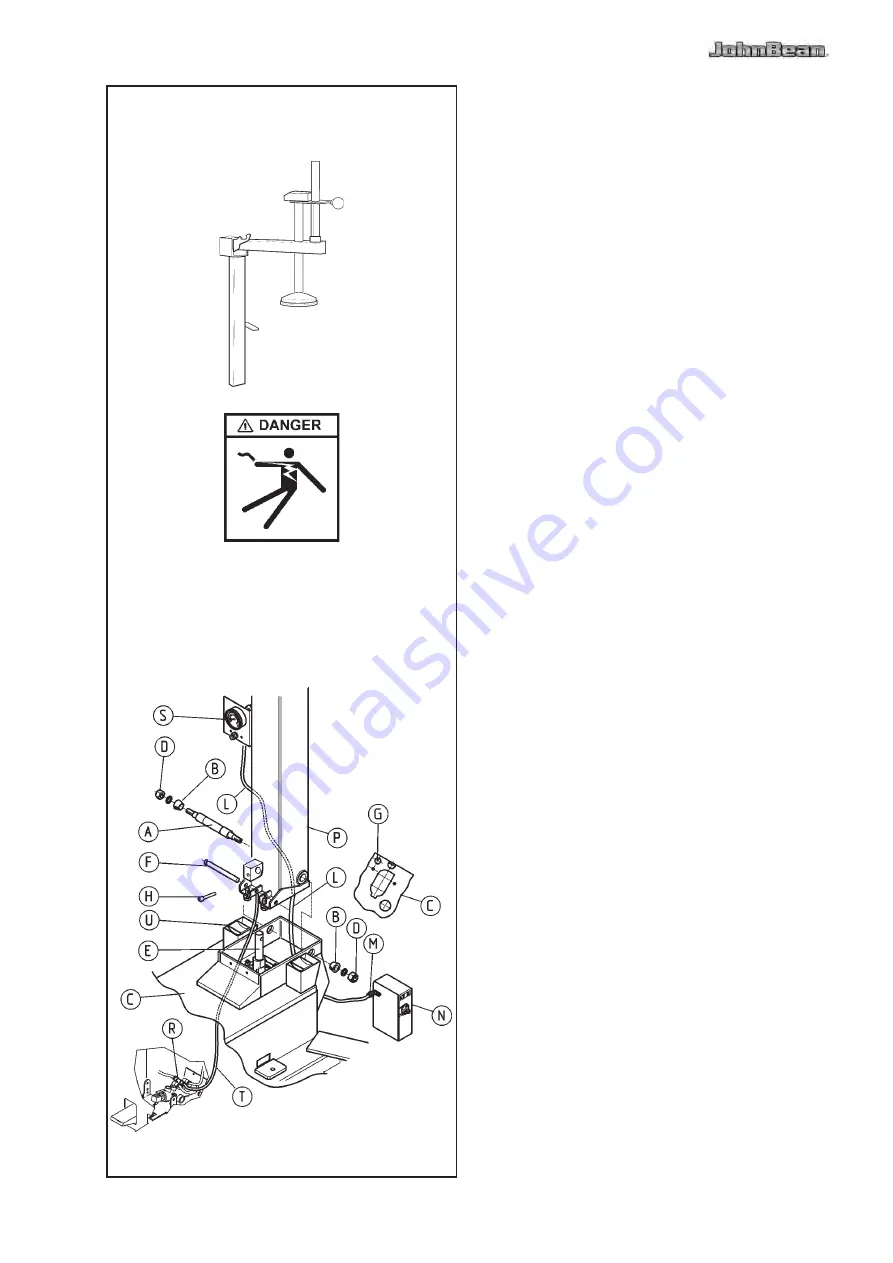

SRA

2.0 INSTAllATION

2.0.1 MODElS WITH SRA ATTACHED

(OPTIONAL PART)

Once placed in the desired location the tire changer

must be bolted to the floor using anchors supplyed with

the machines with Safety Restraint Arm SRA. Concrete

must be steel mesh reinforced.

Tire Changer must be anchored to concrete floor

if equipped with a “Safety Restraint Arm”

(SRA)

.

2.0.2 INSTAllATION INSTRUCTION

The Tire Changer is delivered mounted to a wooden

skid. Remove tire changer from its mounts carefully,

taking care to avoid any back strain.

Install the machine in a covered and dry place. Place

the Tire Changer where proper operation will be

unobstructed to all sides. Operation temperature is

+41/+122 °F (+5/50 °C). The EHP Tire Changer can

work below 32 °F, but some minor modifications are

required: contact your

JBC

distributor for detailed

information.

Concrete must be a minimum of four inches commercial

grade, 3500-4000 PSI, with a cure time of at least 28

days. Steel mesh reinforced.

Follow these instructions carefully to insure proper and

safe operation.

A.

Remove the lube pail by unscrewing the relevant screw.

Remove the carter “

U

” (Fig.12) by unscrewing the

screws “

Z

” (Fig.2.0-1)

b.

Lift the column ‘

P

’ Fig.2.0-1 with an appropriate lifting

tool (crane, fork lift) and a belt of sufficient capacity

(2000N). For this operation it is required to be helped

by a second person. BE CAREFUL NOT TO DAMAGE

THE AIR HOSES. Introduce the air hoses ‘

l

’ through

the hole ‘

I

’ of the cabinet ‘

C

’.

Connect the air hose ‘

T

’ with the quick connector ‘

G

’.

C.

Mount the column ‘

P

’ as shown in Fig.2.0-1 and

connect it to the cabinet through shaft ‘

A

’, nut ‘

D

’ and

the conical bushings ‘

b

’.

IMPORTANT!

THE NUTS ‘D’ MUST BE TIGHTENED ENOUGH

TO ElIMINATE ANY SIDEWISE ClEARANCE

bETWEEN THE COlUMN AND THE CAbINET.