32

Mounting a tyre

Operation manual

T 3300-24

19

17

20

1

2

8. Mounting a tire

Always observe the applicable national guidelines

when mounting tyres.

Mounting of the tyre is feasible much more easily when

prior to mounting a common tyre lubricant is applied

onto the bead and the rim over which the bead will be

mounted. Never use other agents only

supposed

to

lubricate!

•

Clamp or adjust the rim such that the wheel valve is

ap-proximately 180 deg. from the mounting head.

•

Apply sufficient lubricant on tire and rim.

•

Place tire on rim in sloping position (

Fig. 19

).

•

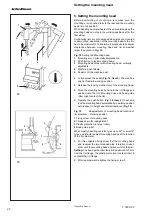

Depress the pedal (

2, Fig. 17

)

to tilt the machine

post into working position.

•

Check mounting head setting, or set as

described under § 5. Setting the mounting head.

•

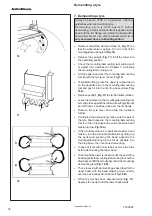

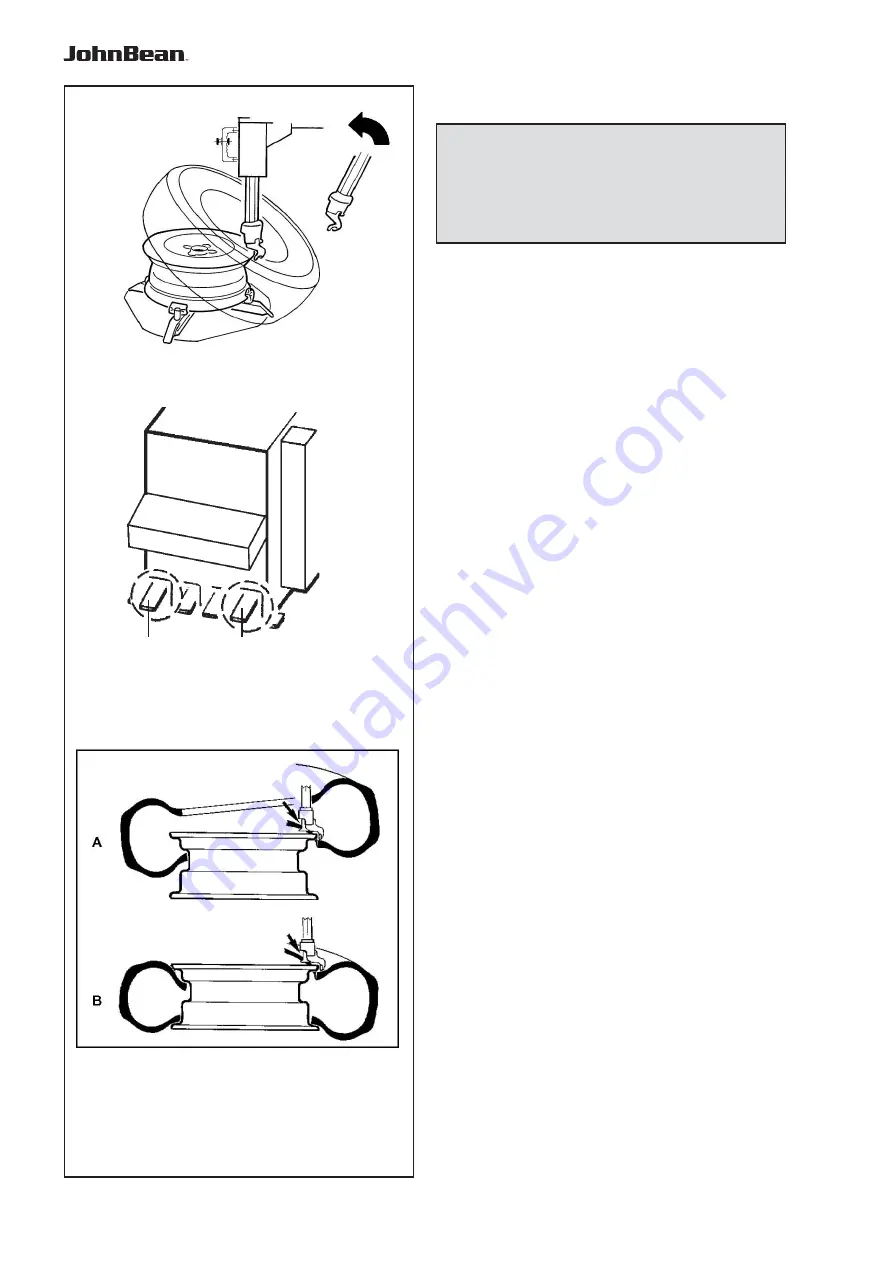

Position the tire relative to the mounting head

such that the lower tire bead runs from below

the mounting nose upwards over the flange of

the bead guide roller (arrow,

Fig. 20 A

).

•

Start mounting by operation of pedal

(1, Fig. 17)

.

During the mounting process observe correct

bead run, otherwise stop and correct by hand,

then proceed until the tire bead has gone

completely over the rim flange.

•

In case of tubed tires put on the tube after

mounting of the lower tire bead. To ensure that

the tube is not dam-aged once fitted, pay

attention to tube position as you continue with

tire mounting.

•

For mounting of the upper tire bead, position tire

again such that the bead runs from below the

mounting nose upwards over the flange of the

bead guide roller (arrow,

Fig. 20 B

).

•

Start mounting by operation of pedal (

1, Fig. 17

).

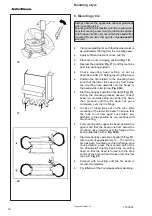

After a part of approximately 10 – 15 cm of the

tire has been mounted over the rim flange, stop

chuck rotation, press the mounted part of the

tire downwards directly behind the mounting

head so that the bead is forced into the drop

centre of the rim and bead tension remains low

(arrow

C

,

Fig. 21

).

•

Proceed with mounting until the tire bead is

mounted completely.

•

For inflation of the tire release wheel clamping.