Page 7

John Bean VPI System II Operators Manual

PRE-INSTALLATION CONSIDERATIONS

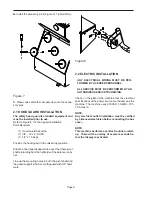

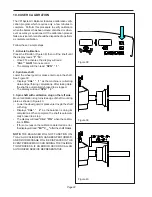

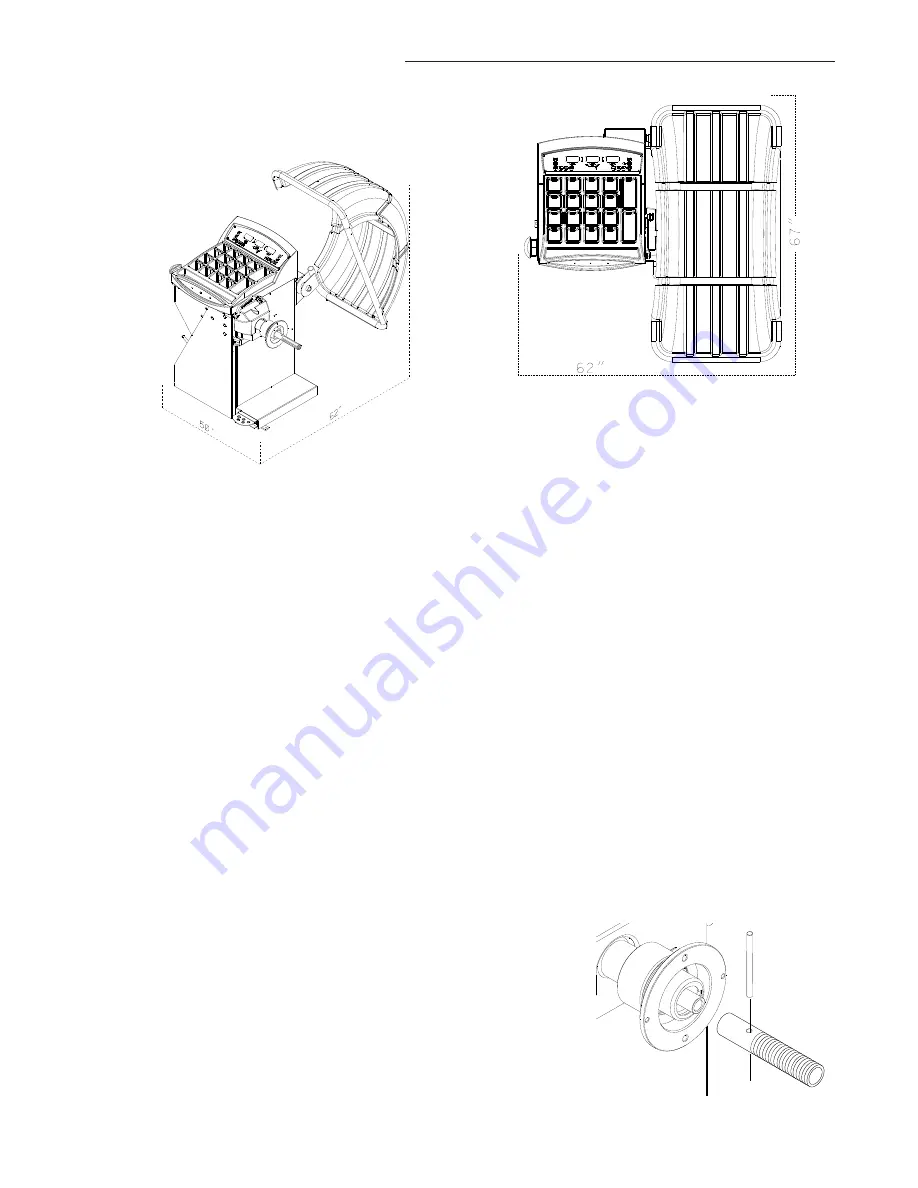

1.7 DIMENSIONS OF THE MACHINE

Figure 4

- Actual Footprint Dimensions.

1.8 REQUIRED INSTALLATION AREA

Make sure that from the operating position the user can

see all of the machine and the surrounding area.

The operator should prevent non authorized persons and/

or objects from entering the area which may create po-

tential hazards.

The machine should be installed on a stable level floor.

Do not install the machine on a uneven floor.

If the balancer is to be installed on a raised floor, the

floor must have a capacity of at least 110lbs per sq ft.

(5000 N/m² - 500 kg/m²).

It is not required to secure the machine to the floor.

Install the machine in a dry, covered area.

The installation of the machine requires a working area

of at least 62” x 67” (1574 x 1702 mm) (Figure 5).

1.9 INSTALLATION INSTRUCTIONS

CAUTION! CAREFULLY REMOVE THE BALANCER

FROM THE PALLET.

Remove the hardware that secures the machine to

the pallet and slide the balancer onto the floor where

it is to be installed.

THE UNIT IS HEAVY AND THE WEIGHT IS NOT

EVENLY DISTRIBUTED.

DO NOT LIFT THE BALANCER BY THE SHAFT.

DROPPING THE UNIT MAY CAUSE PERSONAL IN-

JURY OR EQUIPMENT DAMAGE.

2.0 BALANCER INSTALLATION

Mounting the Shaft Adapter

IMPORTANT!

CHECK THAT THE SURFACES ARE PERFECTLY

CLEAN AND NOT DAMAGED. AN INCORRECT

MOUNTING MAY RESULT IN SIGNIFICANT IMBAL-

ANCE.

A.

Mount the threaded shaft onto the arbor of the bal-

ancer. Tighten firmly using supplied rod. (Figure 6).

Figure 6

Figure 5

- Recommended Work Area

Summary of Contents for VPI SYSTEM II

Page 2: ......

Page 27: ...NOTES ...