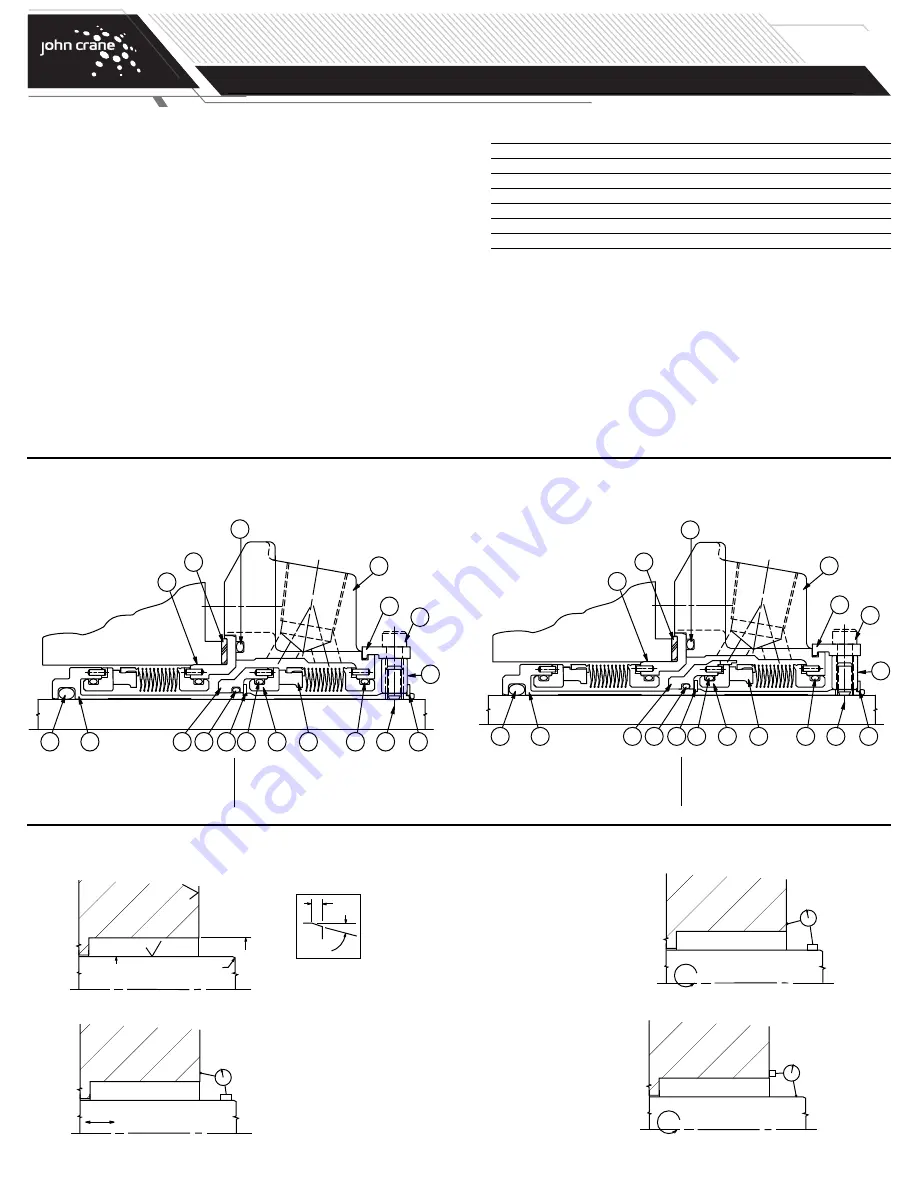

Typical Type 5625 Dual Metal Bellows Cartridge

Seal Arrangement

17

4

6

5

16

13

2

18

1

3

8

14

15

12

11

7

9

10

General Instructions

1.

Study the engineering layout drawing to confirm the proper seal

arrangement for the pump being used. Type 5625 and 5625P seals

are designed for versatility and can be assembled in various ways.

The following instructions describe the standard configurations.

2.

To assure satisfactory operation, handle seal with care. Take particular

caution to see that the lapped sealing faces are not scratched or

damaged.

Preparing the Equipment

1.

Check seal chamber dimensions and finishes.

2.

Measure axial end play (0.003" FIM max.).

3.

Determine squareness of seal chamber face to shaft:

Rotating Mating Ring

- 0.005" FIM max.

Rotating Seal Head

- 0.002" FIM max.

4.

Measure shaft runout (0.002" FIM max.).

63

BORE

SHAFT OR SLEEVE

0.040 LG. X 20˚ CHAM.

6

3

0D +0.000"

- 0.002"

0.040"

20˚

MOVE SHAFT IN AXIAL DIRECTION

BY HAND. NOTE MEASUREMENT

ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SEAL CHAMBER

FACE

Inboard

Side

Outboard

Side

Part Name

1

Mating Ring

7

Collar

13

Sleeve Adapter*

2

O-ring

8

Set Screws

14

Gasket

3

Seal Head Assembly

9

Spacers

15

O-ring

4

O-ring

10

Cap Screws

16

Snap Ring

5

Sleeve Assembly

11

Gland Plate Assembly

17

O-ring

6

O-ring

12

Gland Adapter

18

Snap Ring

*Or pumping ring for 5625P.

Typical Type 5625P (Pumping Ring) Dual Metal Bellows

Cartridge Seal Arrangement

17

4

6

5

16

13

2

18

1

3

8

14

15

12

11

7

9

10

Inboard

Side

Outboard

Side

NOTE:

If measured dimensions exceed those values given, correct the equipment to meet specifications prior to seal installation.

TYPE 5625/5625P

DUAL METAL BELLOWS CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE

2