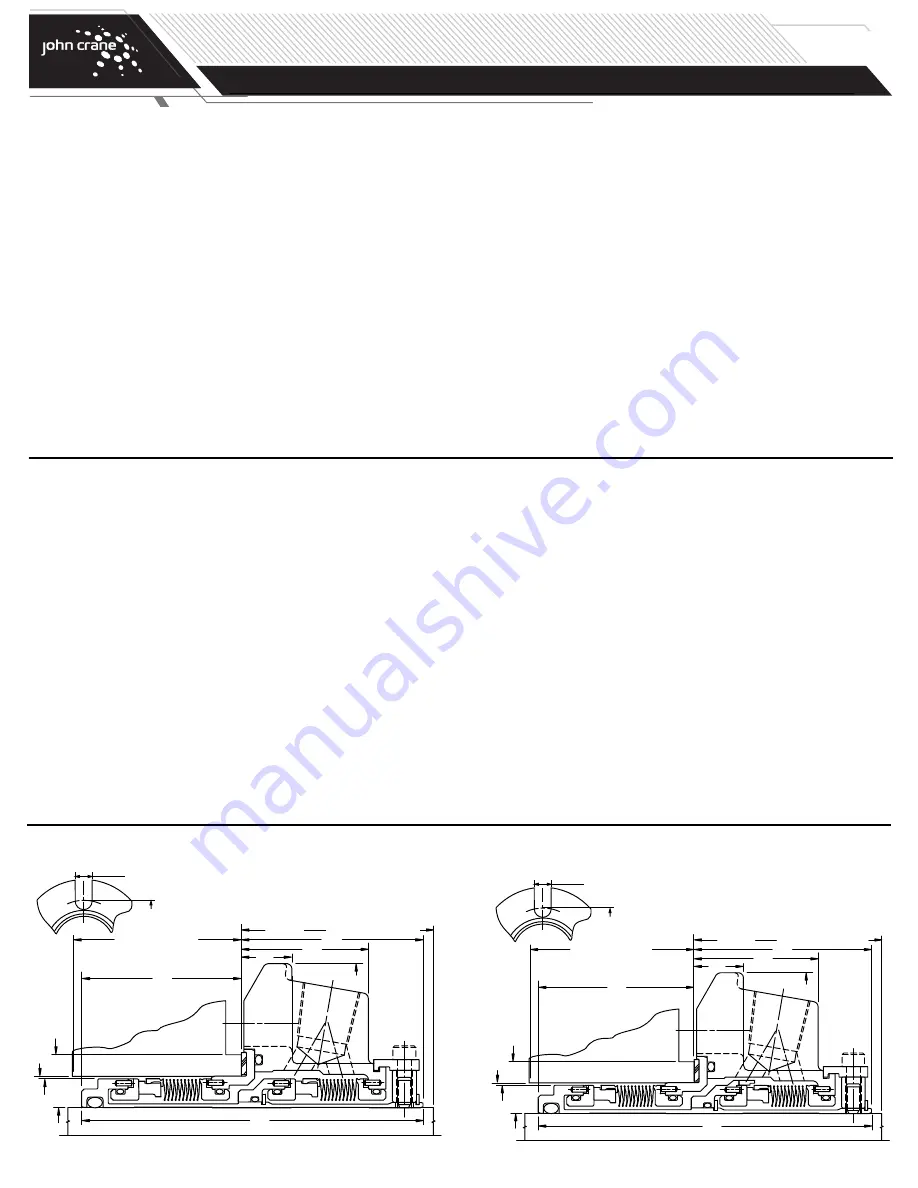

Typical Type 5625 Installation Dimensions

Typical Type 5625P Installation Dimensions

L23

L39

L91 MIN. BOX DEPTH

L92

D1

L90 MIN.

NEAREST OBSTRUCTION

D3

L12

D26

L56

D4

*MIN.

TURN

DIAM.

SLOT

WIDTH

M

N

SLOT

WIDTH

M

N

c

Assemble the Type 5625 or 5625P as follows, referring to the applicable

engineering layout drawing.

NOTE:

These instructions apply to a rotating mating ring configuration.

The seal assembly and mating ring positions could be reversed

should an application require.

NOTE:

Elastomeric O-rings can be damaged or destroyed if care is not

taken. Prior to assembly of O-ring into groove, make sure groove

is clean and free of foreign materials. Lubricate both groove and

O-ring prior to installation with light lube oil (SAE #10 or #20) or

silicone grease (such as Dow Corning compound #4.) For ethylene

propylene elastomers, do not lubricate with petroleum products.

1.

Place gland plate on table with gasket side facing up.

2.

Install lubricated O-ring into outside diameter (OD) groove of mating

ring.

3.

Stand sleeve on its base and slide mating ring over sleeve, align pins

and press in place.

4.

Install set screws in collar.

5.

Loosely attach the spacers to the collar with cap screws.

6.

Set the gland plate assembly gasket side down on table. Install collar on

gland plate assembly and engage spacers into groove, aligning spacers

with pipe taps of gland plate. Uniformly finger tighten the cap screws.

This sets the radial spacing of the cartridge.

7.

Install lubricated O-ring into outside diameter (OD) groove of seal

assembly rear adapter.

8.

Insert seal head assembly in gland plate adapter, align pins and press

in place.

9.

Clean faces of primary and mating rings with denatured alcohol and a

lint-free cloth.

10.

Stand sleeve on its base and slide seal assembly over sleeve until seal

faces touch.

11.

Install lubricated O-ring into ID groove of sleeve adapter.*

12.

Slide sleeve adapter over sleeve, aligning pins of adapter with pins of

sleeve. Push down to engage drive flats until adapter stops at step of

sleeve.

13.

Carefully slide snap ring over the end of sleeve. Using assembly tool,

push the snap ring in place inside the sleeve adapter until it snaps in

Type 5625 Dual Metal Bellows Cartridge Seal Assembly

L23

L39

L91 MIN. BOX DEPTH

L92

D1

L90 MIN.

NEAREST OBSTRUCTION

D3

L12

D26

L56

D4

*MIN.

TURN

DIAM.

*Oversize bore seals only

*Oversize bore seals only

place. Be careful not to scratch the sleeve adapter!

14.

Install lubricated O-ring into outside diameter (OD) groove of outboard

mating ring.

15.

Slide mating ring over sleeve, align pins and press in place.

16.

Install lubricated O-ring into outside diameter (OD) groove of outboard seal

assembly rear adapter.

17.

Place gland plate onto table with gasket side up.

18.

Insert seal assembly in gland plate, align pins and press in place.

Turn gland plate over and confirm that rear adapter is flush with

end of gland plate.

19.

Clean faces of primary and mating rings with denatured alcohol

and a lint-free cloth.

20.

Insert O-ring in face groove of gland plate.

21.

Making sure seal assembly does not fall out, slide gland plate over

sleeve until seal faces touch.

22.

Carefully rotate gland plate until holes in sleeve are lined up with the

collar set screws.

23.

Carefully press down on gland plate and install snap ring over the end

of sleeve.

Do not over compress gland plate or this may damage

the seal.

24.

Tighten set screws until they start to enter the sleeve ID.

25.

Uniformly tighten cap screws on spacers.

26.

Install gasket and sleeve O-ring.

27.

Pressure test according to John Crane Standard QA-5-0569.

*For 5625 or pumping ring for 5625P.

Type 5625 Dual Metal Bellows Cartridge Seal Assembly

(cont.)

TYPE 5625/5625P

DUAL METAL BELLOWS CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE

3