8

ZZ602/6

6.4

IGNITION OF PILOT AND MAIN BURNERS:

WARNING:

If the pilot light is extinguished either intentionally or unintentionally, no attempt should be made to

relight the gas for a minimum of 3 minutes. Ensure that the Electrical supply, Time Control and Selector switches are set

to ‘OFF’.

6.4.1

Set the Thermostat to the lowest or OFF setting.

6.4.2

On the Multifunctional Control, remove the Outlet Pressure test point cover, and a fit pressure test gauge

(refer fig. 4).

6.4.3

On the Multifunctional Control, remove the Gas Pressure Adjustment cover.

6.4.4

Turn ON the Gas supply to the heater, test for gas soundness and purge the whole gas pipe as described in IM/2

and IM/5.

6.4.5

Referring to Fig. 4, press and hold the OPERATING CONTROL, and whilst observing the Pilot Burner, repeatedly

press the Piezo igniter button until the Pilot burner ignites.

Note:

If the Piezo unit should fail to provide a spark, the pilot burner may be ignited by applying a lighted taper to

the pilot burner whilst holding the OPERATING CONTROL depressed.

6.4.6

After 20 seconds release the OPERATING CONTROL and let it spring out; ensure that the Pilot burner remains

alight. If the Pilot burner extinguishes, wait three minutes and repeat steps 6.3.5 and 6.3.6 until Pilot burner

remains alight, holding the OPERATING CONTROL depressed for a longer period than previously.

6.4.7

Ensure that the pilot flame envelops the thermocouple tip, adjusting the Pilot Adjuster as required (refer Figs. 3

and 4).

Note:

This appliance uses a low energy pilot burner, which is factory set at 4 full turns anticlockwise from

closed.

6.4.8

Set the Heater Electricity supply ON.

6.4.9

Set the Time Control to required Heating On periods and the Selector switch to ‘TIMED’.

6.4.10 Set the room thermostat to MAXIMUM.

6.4.11 Ensure that the main burner has now ignited.

6.4.12 Test for gas soundness at the supply, Multifunctional Control, Pilot and Main burners using a proprietary

detection fluid and sealing any leaks found.

6.4.13 Allow heater to operate for a minimum of 15 minutes to ensure stability.

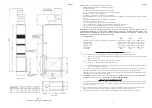

Fig. 3

Pilot Burner Assembly

6.5

MAIN BURNER PRESSURE TEST:

NOTE: AIR HEATER BURNERS ARE FACTORY SET TO PROVIDE A NOMINAL HIGH PRESSURE OUTPUT AS

DETAILED IN SUB PARA 1.1

6.5.1

Referring to Table 5 and Fig. 4 below, ensure that the pressure test gauge indicates the correct burner pressure,

resetting if required as follows:

a.

At the Multifunctional control:

i.

Remove the Burner Pressure Adjuster cover.

ii.

Set the Burner Pressure Adjuster to provide a pressure test gauge indication for the correct burner

pressure as detailed in Table 5.

iii.

Refit the Burner Pressure Adjuster cover.

ZZ602/6

11

7.

INSTRUCTIONS FOR USERS

7.1

If the building is unoccupied, ensure that the Instructions for User are left taped to the air heater for the User, and

Installation Instructions are left at or near the air heater for use on future service calls.

7.2

If the building is occupied, hand the User Instructions over and ensure the User understands:

7.2.1

How to ignite the pilot and burner.

7.2.2

How to operate the thermostat, time control (if fitted) and heater ON/OFF switches and summer air circulation

switch, and that the time control (if fitted) must be reset following a power failure.

7.2.3

How to extinguish the pilot and main burner at the Multifunctional control, and switch off electrical supply to the

heater.

7.2.4

How to remove, clean and re-fit the air filter (if fitted) and at what intervals (i.e. fortnightly, or weekly for new

premises).

7.2.5

How to control the heating system by opening and closing warm air outlets.

7.2.6

How to obtain summer air circulation.

7.2.7

That the air grilles on the heater or heater compartment; grilles and ventilators in the walls, windows or doors of

the building must not be obstructed.

7.2.8

That the heater must be serviced at least once a year by a competent person to ensure efficient and safe operation.

7.2.9

That the red instructions for safe use have been pointed out and understood.

7.2.10 That expert help must be obtained if persistent failure of the pilot burner occurs.

8.

MAINTENANCE

IMPORTANT: Ensure gas and electricity supplies are isolated before commencing any maintenance or replacement of

components. After completion of any maintenance, always test for gas soundness and carry out a complete functional test of the

appliance in accordance with Commissioning Instructions at Sect 6.1 to 6.8 inclusive.

8.1

ROUTINE MAINTENANCE:

8.1.1

Operate the appliance and check for the correct function of the burner and controls.

8.1.2

Turn OFF the gas and electrical supplies to the appliance.

8.1.3

Remove the air heater front panel.

8.1.4

Remove and check the return air filter/cleaner for cleanliness, remove and clean the Air Circulation fan as

detailed in para 8.9.

8.1.5

Remove the Burner and Controls Assembly as detailed in para 8.2. Inspect and clean the main burner and injector

as necessary. Examine the main burner for cracks, including hairline cracks, exchanging the burner as necessary.

8.1.6

Inspect and clear the pilot burner orifice.

8.1.7

Clean the heat exchanger flueways by thoroughly brushing from above and below.

8.1.8

By viewing through the Fan Aperture, and using a torch or similar, examine the heat exchanger externally for signs

of cracks or holes, particularly around welded joints.

8.1.9

Using a torch or similar, introduce a light source into the heat exchanger burner aperture and upper access port,

and again examine the heat exchanger for signs of cracks or holes, particularly around welded joints, whilst again

viewing through the Fan Aperture.

8.1.10 Refit the Air Circulation fan, Burner and Controls Assembly, and air filter/air cleaner.

8.1.11 Light the appliance and note the main burner flame profile. If the flame profile is affected when the Air

Circulation fan switches on, check for any air leaks between the air heater and the base plenum, paying particular

attention to heaters with rear draught diverters. Rectify any air leaks before continuing with this procedure.

8.1.12 Allow the air heater to operate for approximately 15 minutes to ensure stability, and with the main burner lit,

ensure that the operation of Air Circulation fan does not affect the main burner flame profile.

8.1.13 If no defects are found, fully commission the air heater in accordance with the Installation, Commissioning and

Maintenance instructions applicable to the appliance.

Thermocouple

Pilot Burner

Electrode