Position of

Air direct

Air Vents

from outside

JU78 - High Level

132 cm

2

(21 in

2

)

JU78 - Low Level

264 cm

2

(42 in

2

)

JU117 - High Level

197 cm

2

(31 in

2

)

JU117 - Low Level

393 cm

2

(62 in

2

)

JU156 - High Level

261 cm

2

(41 in

2

)

JU156 - Low Level

522 cm

2

(82 in

2

)

Table 1: Minimum Effective Areas

4.

DUCT SYSTEM

(See British Design Manual - Gas fired Warm Air Heating)

4.1

RETURN AIR

4.1.1

If the air heater is installed in a compartment, all return air shall be POSITIVELY ducted from outside the

compartment to the bottom of the unit. It is recommended that the return air duct be not routed directly from the

main occupied area, but from a convenient central area serving the remainder of the building.

4.1.2

The return air system must be constructed of non-combustible material. The flue shall not be run through an area

serving as a return air path. It is extremely important that the correct size of return air grilles and ducting is used.

Return air duct sizes and minimum open areas of return air grilles are as listed in Table 2.

Appliance

Minimum return air

Minimum free area of

duct size

Return air grilles

JU78

300mm x 300mm ( 12 in x 12 in )

1887cm

2

(291 in

2

)

JU117

450mm x 300mm ( 18 in x 12 in )

2796cm

2

(434 in

2

)

JU156

600mm x 300mm ( 24 in x 12 in )

3725cm

2

(578 in

2

)

Table 2

Minimum Return Air and Free Area

4.1.3

An adequate and unobstructed return air path is essential from areas not served by a directly ducted return and to

which warm air is delivered. All such rooms should be fitted with relief grilles which have a free area of

0.0088m

2

/kW (1in

2

/250Btu/h) of heat supplied to the room. The only exceptions are kitchens, bathrooms and

WC.’s.

4.1.4

All duct work in the room or internal space in which the heater is installed shall be mechanically secured, and

sealed with ducting tape.

4.2

WARM DELIVERED AIR

4.2.1

All duct work, including riser ducts, should be fully insulated with 50mm (2in) fibreglass or similar. If short

extended duct runs are taken below floor level these should be similarly insulated, and in addition wrapped with a

sound vapour proof barrier, and protected from crushing.

4.2.2

The duct system should be carefully designed (as given in the guidelines in the British System Design Manual) to

suit the needs of its specific heating requirements and building layout. The type of duct system, (i.e. radial/

extended plenum/stepped) should be installed using the least number of fittings to minimise airflow resistance.

3

ZZ602/6

16

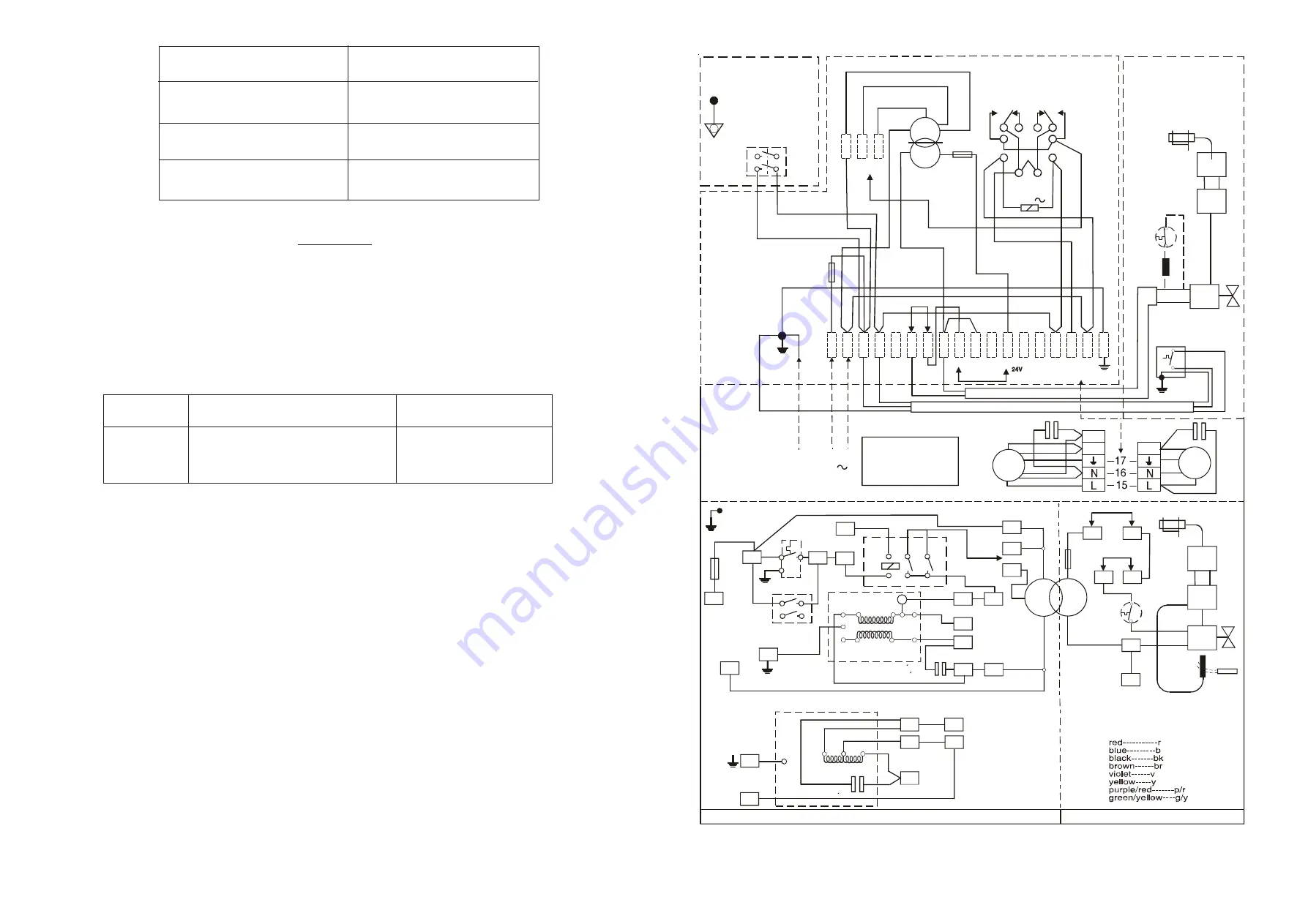

Fig. 5

JU Series Air Heaters Wiring Diagram

N

16

5

7

v

TAP

r

br

T4

9

WARNING

7 AND 9 ARE

OV

DO NOT EARTH

11

T1

T2

8

y

y

A

B

p/r

p/r

1.6A

6.3A

N/C

5

3

1.6A

TRANSFORMER

6

7

2

1

8

br

b

OV

24V

240V

FAN

210V

PWR

L

N

br

br

b

b

br

g/y

br

br

240V

FAN VOLTS

SELECTOR

EQUIPOTENTIAL

BONDING POINT

SUMMER

SWITCH

THESE ITEMS IN

BURNER CHAMBER

FLOOR

WARNING

DO NOT CONNECT

TO EARTH

4

N/C

N/O

240V

210V

N/O

bk

bk

6

24V

24V

GAS

PILOT

THERMO

COUPLE

GAS

CONTROL

INTERRUPTOR

UNIT

O’HEAT

LIMIT

CONTROL

AIR

TEMPERATURE

PROBE

THESE ITEMS MOUNTED

ON FRONT BULKHEAD

GAS

CONTROL

LIMIT

SWITCH

O’HEAT

LIMIT

CONTROL

AIR TEMP.

PROBE

INTERRUPTOR

UNIT

LIMIT

SWITCH

JU156

ONLY

N

NC

Wire colour code where indicated

LABEL REF NO 1000-2205540-02

CIRCUIT DIAGRAM: JU78, JU117 AND JU156 AIR HEATERS

y

MAIN

AUX

WINDINGS

FAN MOTOR

JU156 C1=16uF

WARNING:

THERMOSTAT

CIRCUIT

IS 24V

NOT MAINS

JU117 C1=7uF

JU117 & JU156

JU78

JU156

ONLY

15

20

19

18

15

L

16

N

L

F1

F2

14

240v

LO

210V

240V

HI

NC

NC

N

16

17

N

L

17

g/y

b

br

b

b

b

b

b

g/y

g/y

br

br

br

r

br

br

br

6.3A

DIRECT EARTH

POINT (DEP)

br

br

C1

Z2

U1

br

br

br

6

2

b

7

8

1

3

17

br

y

BUTT

CONNECTOR

bk

IN

g/y

b

OUT

THIS SIDE

16

15

14

13

12

11

10

9

8

2 CORE CABLE

3 CORE CABLE

7

6

5

LINK A

4

F

2

NC

OV

T2

NC

T1

NC

240V

FAN

PWR

L

N

NC

y

bk

y

r

SL

EE

V

E T

H

IS

E

N

D

br

LINK B

T4

OV

24V

GAS

CONTROL

FAN

SW

1

F

N

19

20

L

br

g/y

g/y

DIRECT EARTH

POINT

br

y

v

y

bk

p/r

br

br

br

br

br

br

br

b

br

r

br

p/r

b

b

18

Z1

U2

OL

AUX. WINDING

MAIN WINDING

FAN MOTOR

RELAY

SUMMER

SWITCH

FAN

CONTROL

24V

0V

S

L

N

P

FAN

MOTOR

FAN

CONTROL

FAN

MOTOR

P

S

T

JU78

JU117

AND

JU156

8uF

LINKS A AND B

A: REMOVE WHEN USING VOLT

FREE TIMED OR MANUAL

SWITCH.

B: REMOVE WHEN USING

THERMOSTAT.

SUPPLY 240V

50 Hz

FUSED 13A