3

CONTENTS

PAGE

1.

General

. ....................................................................................................... 5

1.1

Description of the appliance .......................................................................... 5

1.2

Technical safety equipment ........................................................................... 6

1.3

Technical description ..................................................................................... 8

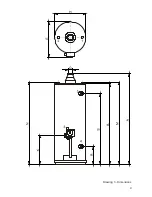

1.3.1

Dimensions .................................................................................................... 8

1.3.2

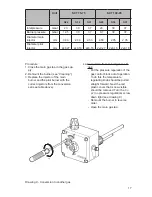

Technical data ............................................................................................. 10

2.

For the installer

. ...................................................................................... 11

2.1

Installation instructions ................................................................................ 11

2.1.1

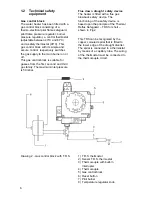

Installation .................................................................................................... 11

2.1.2

Water connections ...................................................................................... 11

2.1.3

Gas connection ........................................................................................... 12

2.1.4

Flue system ................................................................................................. 13

2.1.5

Draught diverter ........................................................................................... 13

2.2

Commissioning ............................................................................................. 14

2.3

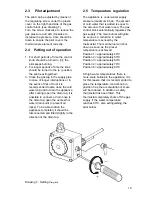

Pilot adjustment ............................................................................................ 15

2.4

Putting out of operation ................................................................................ 15

2.5

Temperature regulation ................................................................................ 15

2.6

Setting the nominal heat input ...................................................................... 16

2.7

Conversion procedure ................................................................................. 16

2.8

Maintenance ................................................................................................ 18

2.8.1

Sacrificial anode .......................................................................................... 18

2.8.2

Cleaning ....................................................................................................... 19

2.8.3

Decalcification ............................................................................................. 19

2.8.4

Spare parts .................................................................................................. 19

2.9

Inlet combination .......................................................................................... 20

2.10

Fault finding ................................................................................................. 20

2.11

Gas smell ..................................................................................................... 20

2.12

Condensation ............................................................................................... 20

3.

For the user

. ............................................................................................. 21

3.1

Commissioning ............................................................................................. 21

3.2

Use .............................................................................................................. 21

3.3

Putting out of operation ................................................................................ 21

3.4

Fault finding ................................................................................................. 22

4.

Warranty

. .................................................................................................. 23

Summary of Contents for SCT 100-95 G

Page 9: ...9 Drawing 3 Dimensions...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28 0308 254 R1...