Minerals that are naturally found in water cause the water to

be electrically conductive . Water conductivity is measured in

micro Siemens per centimeter (uS/cm) . Mineral content, also

described as “water hardness” is usually measured in grains per gallon . Because of the variety of minerals that are found in water, there is no

direct correlation between water hardness and conductivity, but generally the higher the mineral content, the higher the conductivity .

The Canister Steam Humidifier is designed to operate on water with conductivity between 125 and 1,250 uS/cm . This correlates loosely with

water with hardness between 3 and 36 grains/gallon . Water that is considered “hard” and also softened water work well in the humidifier . The

humidifier will make steam when plumbed to low-conductivity water but it takes longer to reach nominal capacity .

with low conductivity water, it may take the humidifier one week or more of operation to reach rated capacity, especially if it

is wired to operate on 120 volts. when operating on 240 volts, the humidifier usually will reach nominal capacity within a few

hours, even with lower conductivity water.

As water in the canister boils and turns into steam, minerals are left behind . The remaining minerals, if they remain in solution in the water,

increase the conductivity of the water . Minerals also deposit onto the submerged portions of the electrodes rendering those areas ineffective . As

this occurs, the level of water in the canister rises to expose uncoated electrode surface .

SPeCIfICaTIonS & DIMenSIonS

Table 1 – Specifications

Voltage

kw

Maximum steam capacity

nominal Current draw (amps)

Humidifier unit operating weight

gal/day

amps

lbs

120V

1 .4

11 .5

11 .5

23

208V

2 .4

20 .5

11 .5

23

240V

2 .8

23 .3

11 .5

23

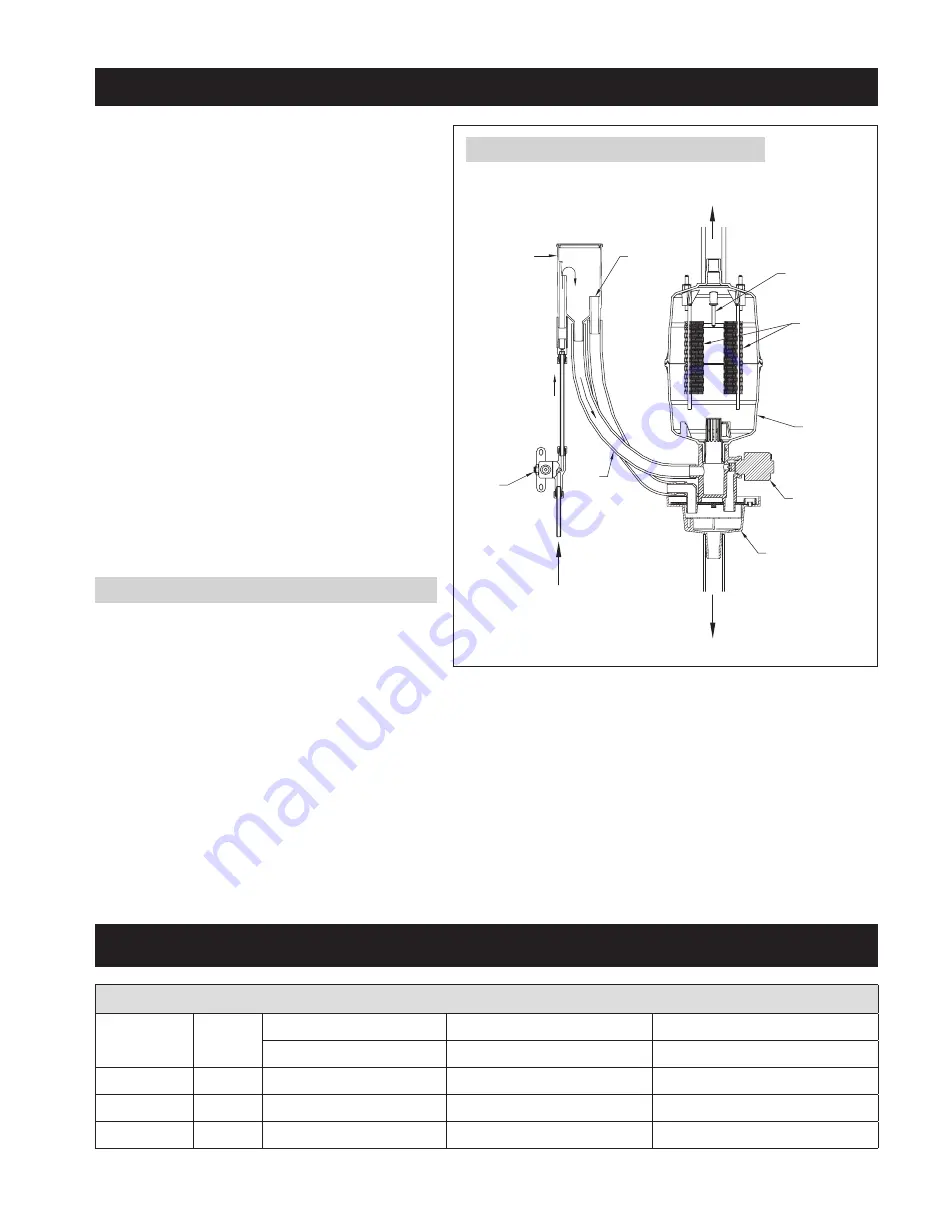

The Canister Steam Humidifier delivers humidity in the form

of steam to the conditioned space via the HVAC system

duct or optional Fan Pack . The humidifier generates steam

by energizing two electrodes that extend into a canister

of water . Current flowing between the electrodes causes

the water to boil, creating steam . Water is introduced to

the humidifier through a fill valve to a fill cup located in

the top of the cabinet . The fill cup serves as an overflow

reservoir and provides an air gap between the humidifier

and water source . The steam canister is filled from the

bottom . The canister is seated in a drain cup assembly

which includes a drain valve . The drain and fill valves work

together to maintain water level in the canister to deliver

the rated steam capacity based on the electrical conductivity

of the water and to temper drain water . See

figure 1

for

representation of fill and drain system and canister .

Steam is delivered into the airstream through a dispersion

tube mounted in the HVAC system ductwork . Openings in the

dispersion tube are fitted with “tubelets” which extend into

the center of the tube . The design of the dispersion tube and

tubelets distribute steam over a wide area in the duct and

direct any condensed moisture back into the steam hose .

PRInCIPleS of oPeRaTIon

fIGURe 1 – fill and Drain System and Canister

90-1522

Steam

Outlet

Drain

Supply

Water

Drain Cup

Drain Valve

Canister

Electrodes

High Water

Level Sensor

Flow Control

Orifice

Inlet

Fill Valve

Overflow

Fill

Fill Cup

waTeR QUalITy

3