CHooSInG a loCaTIon

DISPeRSIon TUbe

When choosing a location for the dispersion tube three things must be considered: Location in duct, elevation with respect to the humidifier, and

distance from humidifier to dispersion tube .

Duct location and absorption Distance

The preferred location for the dispersion tube is in a supply duct because higher temperature air will more readily absorb the moisture . Whether

installed in a supply or return, the dispersion tube must be in a straight section of duct to avoid turbulent air and must be far enough upstream

of any obstruction or bends in the duct to allow the steam to be fully absorbed to prevent condensation . The exact distance from obstructions in

the duct depends on air temperature, RH set point, and airflow velocity in the duct .

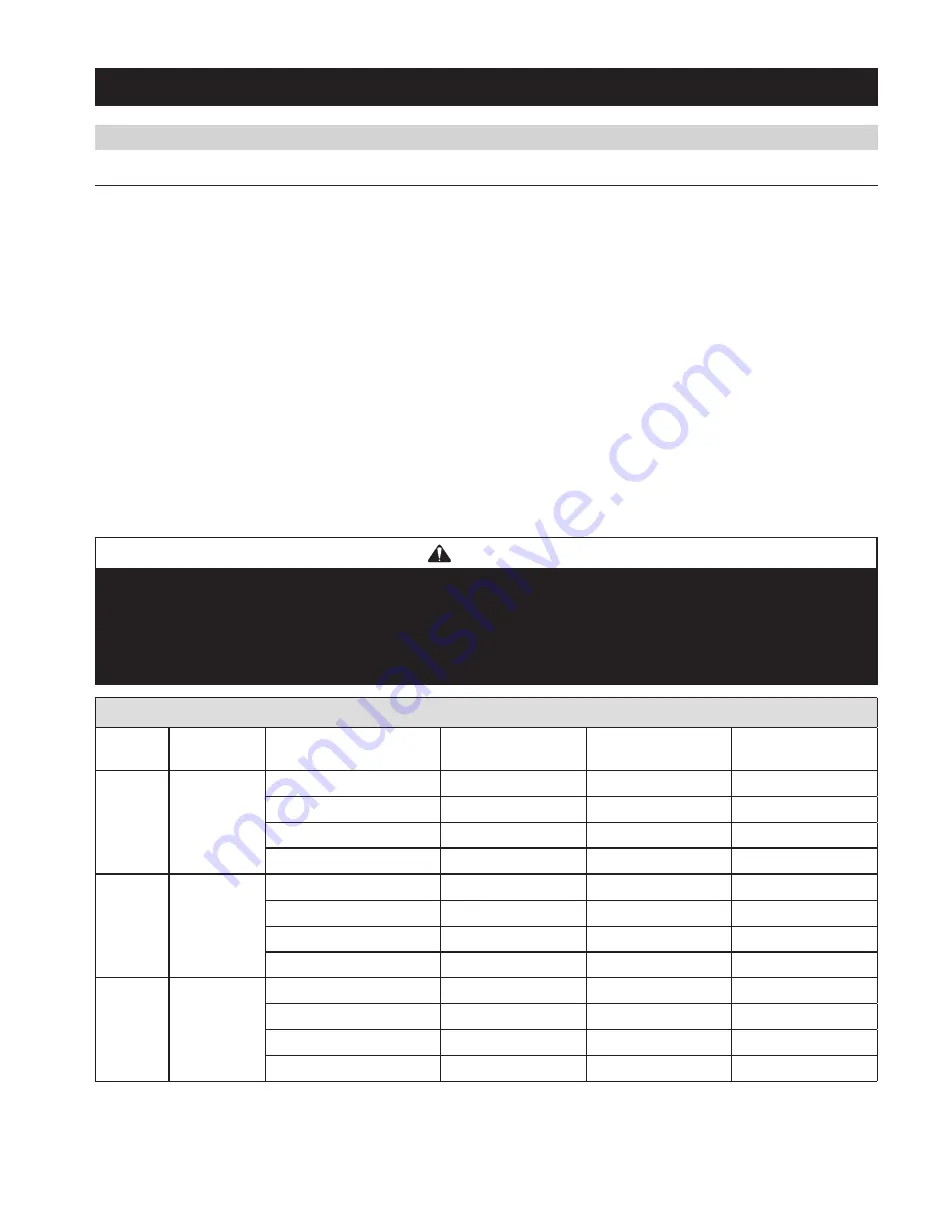

Table 2

provides absorption distance for typical conditions .

The higher the RH setting, the longer the absorption distance . Warmer air shortens the absorption distance . If absorption distance is a concern,

install dispersion tube in supply duct and configure humidifier and control to operate only during HVAC system heat call . When installing the

humidifier in a system with variable speed blower, determine absorption distance based on airflow at the lowest speed .

The dispersion tube must be mounted with the plate on a vertical surface with the tube angled up as shown in

figure 3

. The steam outlets must

face up regardless of the airflow direction in the duct . The plate is labeled “UP” to indicate proper orientation .

If the dispersion tube is mounted on insulated ductwork, make sure insulation is not more than 2” thick at tube location to prevent insulation

from blocking first steam outlet .

note:

If two dispersion tubes are installed in one duct, double the dispersion distances . If three dispersion tubes are installed, triple the

dispersion distance . Position dispersion tubes so one does not discharge directly onto another .

*Velocity in feet per minute = Duct airflow volume in cubic feet per minute / duct area in square feet .

Example: 1,200 cfm through 16” x 12” duct = 1,200/(12 x 16/144 sq . in ./sq ft .) = 1,200/1 .333 = 900 fpm

InSTallaTIon InSTRUCTIonS

Table 2 – absorption Distance (Minimum distance from dispersion tube downstream to any obstruction or bend in duct)

Input

Power

Humidifier

output

airflow Velocity*

70°f & 30% RH

Setpoint

70°f & 45% RH

Setpoint

65°f & 45% RH

Setpoint

120 V

11 .5 gal/day

300 fpm

7"

11"

13"

600 fpm

3"

6"

7"

1200 fpm

2"

3"

3"

1800 fpm

< 2"

2"

2"

208 V

20 .5 gal/day

300 fpm

13"

19"

23"

600 fpm

6"

10"

12"

1200 fpm

3"

5"

6"

1800 fpm

2"

3"

4"

240 V

23 .3 gal/day

300 fpm

15"

23"

28"

600 fpm

6"

12"

13"

1200 fpm

5"

6"

7"

1800 fpm

3"

4"

5"

CaUTIon

Each humidifier requires its own steam hose and dispersion tube. Do not connect steam hoses from more than one humidifier

together. Back-pressure from one humidifier can lower the water level in the canister in the other humidifier and cause

operational problems.

Do not install the dispersion tube in a duct with greater than 2 in. wg static pressure. High duct pressure can cause back-

pressure in the canister which can result in unstable unit operation.

5