501562-UIM-A-0909

2

Johnson Controls Unitary Products

INSPECTION

As soon as a unit is received, it should be inspected for possible dam-

age during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information.

Requirements For Installing/Servicing R-410A Equipment

•

Gauge sets, hoses, refrigerant containers, and recovery systems

must be designed to handle POE oils and the higher pressures of

R-410A.

•

Manifold sets should be 800 PSIG high side and 250 PSIG low

side with 550 PSIG low side retard.

•

All hoses must have a 700 PSIG service pressure rating.

•

Leak detectors should be designed to detect HFC refrigerant.

•

Recovery equipment (including refrigerant recovery containers)

must be specifically designed to handle R-410A.

•

Do not use an R-22 TXV.

•

A liquid-line filter drier is required on every unit.

LIMITATIONS

The unit should be installed in accordance with all National, State, and

Local Safety Codes and the limitations listed below:

1.

Limitations for the indoor unit, coil, and appropriate accessories

must also be observed.

2.

Only variable speed air handlers or variable speed furnaces should

be used with these models.

3.

The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed to

operate against any additional external static pressure.

4.

The maximum and minimum conditions for operation must be

observed to ensure a system that will give maximum performance

with minimum service.

5.

The unit should not be operated at outdoor temperatures below 60°

F without an approved low ambient operation accessory kit

installed.

6.

The maximum allowable line length for this product is 75 feet.

7.

Indoor evaporator coil orifice

must

be removed prior to the

installa-

tion

of a factory supplied balanced port TXV kit.

SECTION III: UNIT INSTALLATION

LOCATION

Before starting the installation, select and check the suitability of the

location for both the indoor and outdoor unit. Observe all limitations and

clearance requirements.

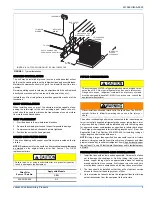

The outdoor unit must have sufficient clearance for air entrance to the

condenser coil, for air discharge, and for service access. See Figure 1.

NOTE:

For multiple unit installations, units must be spaced a minimum

of 18 inches apart (coil face to coil face.).

If the unit is to be installed on a hot sun exposed roof or a black-topped

ground area, the unit should be raised sufficiently above the roof or

ground to avoid taking the accumulated layer of hot air into the outdoor

unit.

Provide an adequate structural support.

ADD-ON REPLACEMENT/RETROFIT

When this unit is being used as a replacement for an R-22 unit, it is

required that the outdoor unit, indoor coil, and metering device all be

replaced. Line-set change out is also recommended. The following

steps should be performed in order to insure proper system operation

and performance.

1.

Change-out of the indoor coil to an approved R-410A coil with the

appropriate metering device.

2.

Change-out of the line-set when replacing an R-22 unit with an

R-410A unit is highly recommended to reduce cross-contamination

of oils and refrigerants.

3.

If change-out of the line set is not practical, then the following pre-

cautions should be taken.

•

Inspect the line set for kinks, sharp bends, or other restrictions,

and for corrosion.

•

Determine if there are any low spots which might be serving as oil

traps.

•

Flush the line set with a commercially available flush kit to

remove as much of the existing oil and contaminants as possible.

•

Install a suction line filter-drier to trap any remaining contami-

nants, and remove after 50 hours of operation.

4.

If the outdoor unit is being replaced due to a compressor burnout,

then installation of a 100% activated alumina suction-line filter drier

is required, in addition to the factory installed liquid-line drier. Oper-

ate the system for 10 hours. Monitor the suction drier pressure

drop. If the pressure drop exceeds 3 psig, replace both the suction-

line and liquid-line driers. After a total of 10 hours run time where

the suction-line pressure drop has not exceeded 3 psig, replace the

liquid line drier, and remove the suction-line drier. Never leave a

suction-line drier in the system longer than 50 hours of run time.