Johnson Controls Ducted Systems

6052931-UAI-A-0121

ACCESSORY KIT INSTALLATION MANUAL

Electric Heat Kit (6HK Series)

For Use with Models: AP, AE, AVC, AVV, AHR, AHE, AHV, MP, ME, MVC, RFCX*E, RFCX*P, PHE, and PCE

General information

These instructions cover installation of the 6HK series of elec-

tric heat kits with the following:

• AP, AE, AVC, AVV, AHR, AHE, AHV, RFCX*E, and

RFCX*P single-piece air handlers

• MP, ME, and MVC modular air handlers

• PHE and PCE residential packaged units

The 6HK series of electric heat kits use a single polarized plug

to easily connect the equipment power and controls.

These electric heat kits are used for applications of electric

heat, cooling with electric heat, and heat pump with electric

heat. Each of the air handler and residential packaged unit

models are approved for use with specific electric heat kits. The

unit installation instructions, technical guide, or name plate list

the possible combinations and other important electrical data

and limitations. Refer to the unit installation instructions for fur-

ther electrical specifications.

Clearance

All installations of the 6HK electric heat kits are approved for

zero clearance to combustibles when the minimum speed tap

on the blower motor is set according to the equipment installa-

tion instructions or nameplate. See the equipment installation

instructions for more information on changing motor speed

taps.

WARNING

ELECTRICAL SHOCK HAZARD

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation must conform with

local building codes or, in the absence of local codes, with

National Electrical Code ANSI/NFPA 70-1996 or current edi-

tion.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Shut OFF electric power at unit disconnect and/or service

panel before beginning the following procedures.

Failure to carefully read and follow all instructions in this man-

ual can result in malfunction, property damage, personal

injury, and/or death.

Verify edges of foil faced insulation are not in contact with any

exposed electrical connections.

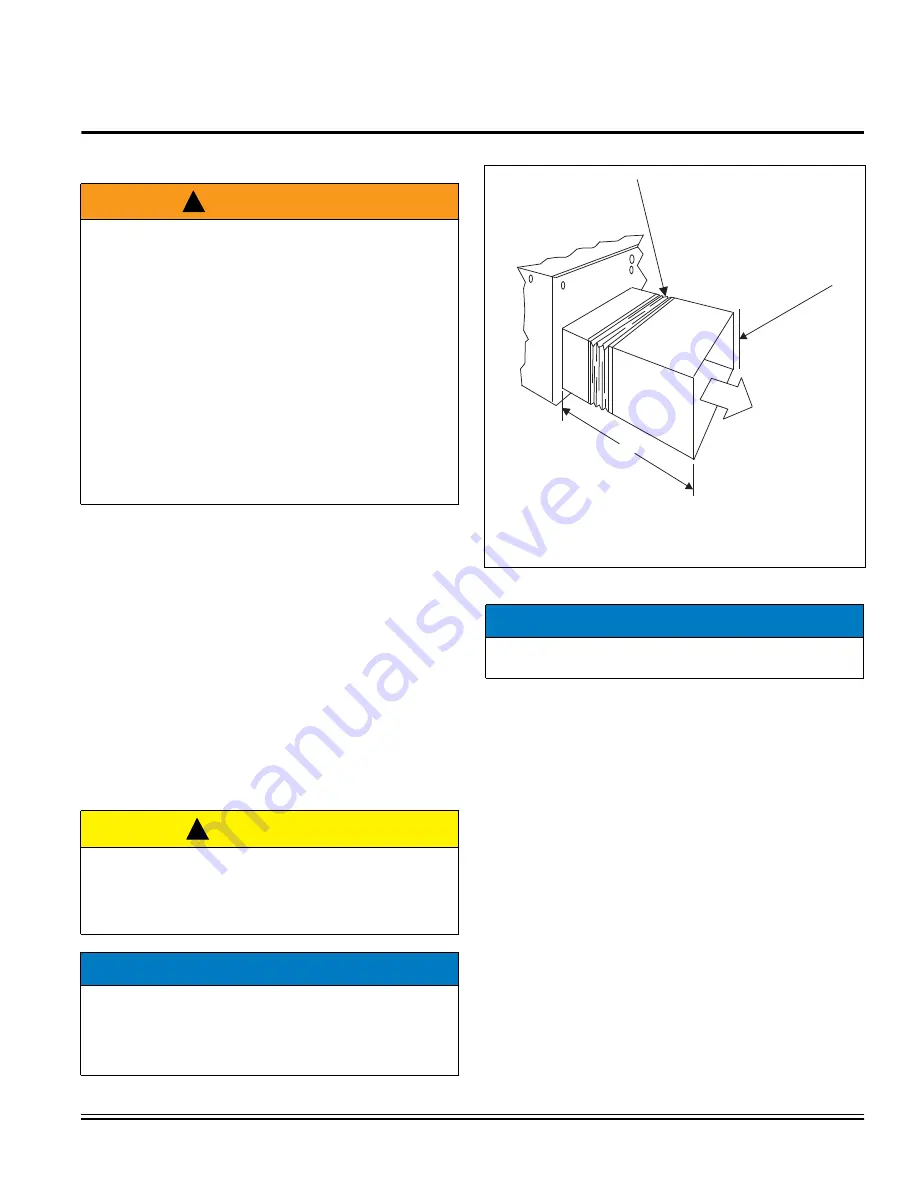

CAUTION

Unit is approved for zero clearance to combustible material

and when equipped with electric heat a minimum clearance

of 1 in. must be maintained on all sides of the supply duct

and/or plenum for 3 ft as shown in the detail in Figure 1 for

the 20 kW and 25 kW electric heat kits only.

NOTICE

In some horizontal applications, the service disconnects on

the electric heat kits must be rotated 180° so the up position

of the disconnect is the ON position. This service disconnect

orientation change is required by UL 1995, Article 26.19 (in

reference to all circuit breakers).

!

!

Figure 1:

Duct work clearance

NOTICE

The electric heat kit should be installed before the supply air

duct is attached to the supply air opening flanges.

MINIMUM CLEARANCE

1” on all sides for the first 3’

of duct from 20 & 25 kw units.

For all other heaters,

zero inch clearance on all

sides for entire length of duct.

FLEXIBLE DUCT COLLAR

NOTE:

For units applied with a roof

curb, the minimum clearance

may be reduced from 1 inch to

1/2 inch between combustible

roof curb material and the

supply duct.

A0238-001

3’