368261-UIM-B-1008

26

Johnson Controls Unitary Products

ADJUSTMENT OF FAN CONTROL SETTINGS

Cooling -

The airflow delivered by the furnace during cooling operation

can be adjusted to match the cooling capacity of the A/C condensing

unit. This is done by moving the COOL jumper on the control board to

give the desired airflow.

Do not move the motor wires to different positions on the

furnace control board!

The jumper has four positions, which will deliver sufficient airflow in

cooling mode for the cooling capacities shown in Table 13. The CFM

delivery on each jumper position is shown in Table 13.

Continuous Fan Operation -

The airflow delivered by the furnace dur-

ing continuous fan operation can be adjusted as desired. This is done

my moving the FAN jumper on the control board to give the desired air-

flow.

Do not move the motor wires to different positions on the

furnace control board!

The jumper has three positions. The "H" position delivers maximum air-

flow, 100% of the blower capacity. Position "M" delivers approximately

70% of the blower capacity. And Position "L" delivers minimum airflow,

approximately 40% of the blower capacity.

SECTION VIII: SAFETY CONTROLS

CONTROL CIRCUIT FUSE

A 3-amp fuse is provided on the control circuit board to protect the 24-

volt transformer from overload caused by control circuit wiring errors.

This is an ATO 3, automotive type fuse and is located on the control

board.

BLOWER DOOR SAFETY SWITCH

This unit is equipped with an electrical interlock switch mounted in the

burner compartment. This switch interrupts all power at the unit when

the panel covering the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel that covers the

blower compartment being in place and properly positioned.

ROLLOUT SWITCH CONTROLS

These controls are mounted on the burner assembly. If the temperature

in the burner area exceeds its set point, the ignition control and the gas

valve are de-energized. The operation of this control indicates a mal-

function in the combustion air blower, heat exchanger or a blocked vent

pipe connection. Corrective action is required. These are manual reset

controls that must be reset before operation can continue.

TABLE 13:

Cooling Airflow - A/C Capacity in Tons

Models

Jumper Position

H

MH

ML

L

60/1200

3

2-1/2

2

1-1/2

80/1200

3

2-1/2

2

1-1/2

80/1600

4

3-1/2

3

2-1/2

100/1600

4

3-1/2

3

2-1/2

100/2000

5

4

3-1/2

3

120/2000

5

4

3-1/2

3

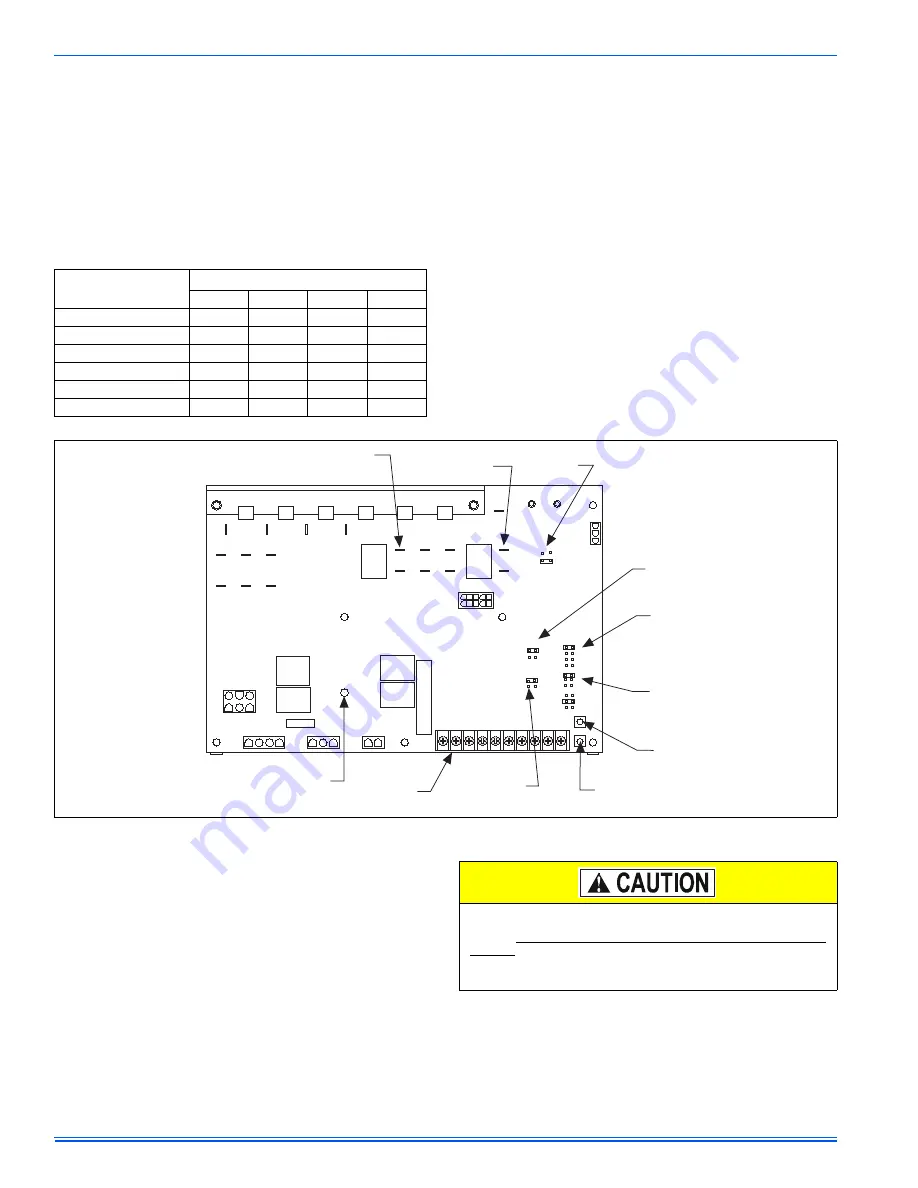

FIGURE 29:

Furnace Control Board

Diagnostic

Light

Low

Voltage

Terminals

Humidistat

Jumper

Last

Error

Button

Test

Button

Continuous

Fan Speed

Jumper

Cooling

Speed

Jumper

Heat Pump

Jumper

Zoning

Jumper

EAC

Terminals

Humidifier

Terminals

ZONE

CONTROL

NO

YES

EXT

PRESSURE

SENSOR

TEST

BUTT

ON

ERRORBUTT

ON

120V

AC

120V

AC

XFORMER

NEUTRAL

NEUTRAL

XFORMER

GROUND

WHITE

BLOWER

BLACK

BLUE

BLOWER

BLOWER

BLOWER

YELLOW

BLOWER

RED

24V

AC

MODULA

TE

COIL

GAS

V

AL

VE

PRIMARY

LIMIT

AUX

LIMIT

AIR

SW

TEMP

SENSOR

HUMIDIFIER

NEUTRAL

HOT

INDUCER

NEUTRAL

HOT

IGNITER

NEUTRAL

HOT

NEUTRAL

HOT

EAC

EAC

FLAME

ROD

FLAMEVOL

TAGE

ID

PLUG

HEA

T

PUMP

HUMIDIST

A

T

YES

NO

YES

NO

AT

R

CONT

FAN

COOL

NOM

-10F

+10F

LMH

L

ML

MH

H

LO

COMP

HI

COMP

O

DHUM

Y1

Y/Y2

W

R

G

C

Main power to the unit must still be interrupted at the main power

disconnect switch before any service or repair work is to be done to

the unit. Do not rely upon the interlock switch as a main power dis-

connect.

Blower and burner must never be operated without the blower

panel in place.