288591-BIM-C-0408

8

Johnson Controls Unitary Products

Service Access

Access to all serviceable components is provided at the

following locations:

• Blower compartment access panel

• Electrical/Filter access panel

• Compressor access panel

• Refrigerant connections

Refer to Figures 1 and 3 for location of these access locations

and minimum clearances in Table 4.

Refer to Figure 11 for the R-410A quick reference guide.

Thermostat

The room thermostat should be located on an inside wall

approximately 56" above the floor where it will not be subject to

drafts, sun exposure or heat from electrical fixtures or

appliances. Follow manufacturer's instructions enclosed with

the thermostat for general installation procedure. Six color

coded insulated wires (minimum #18 AWG) should be used to

connect thermostat to unit. See Figures 7 and 8.

Power And Control Wiring

Field wiring to the unit must conform to provisions of the current

N.E.C. ANSI/NFPA No. 70 or C.E.C. and/or local ordinances.

The unit must be electrically grounded in accordance with local

codes or, in their absence, with the N.E.C./C.E.C. Voltage

tolerances which must be maintained at the compressor

terminals during starting and running conditions are indicated

on the unit Rating Plate and Table 5.

The wiring entering the cabinet must be provided with

mechanical strain relief.

A fused disconnect switch should be field provided for the unit.

If any of the wire supplied with the unit must be replaced,

replacement wire must be of the type shown on the wiring

diagram.

Electrical line must be sized properly to carry the load. Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

Refer to Figures 7, 8 and 9 for typical field wiring and to the

appropriate unit wiring diagram for control circuit and power

wiring information.

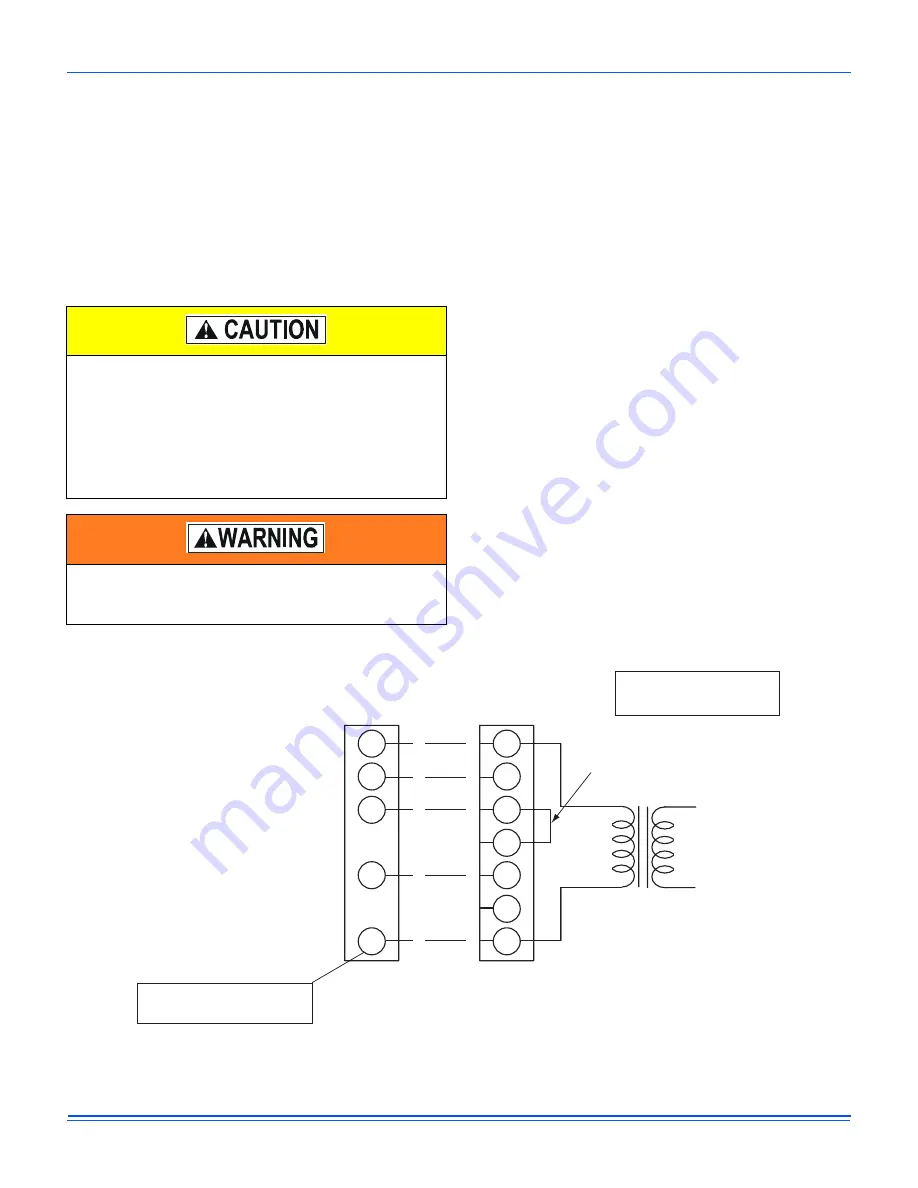

Figure 7: Typical Field Control Wiring Diagram Single Stage Thermostat

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system. Gauge sets, hoses, refrigerant

containers and recovery systems must be designed to

handle R-410A. If you are unsure, consult the

equipment manufacturer. Failure to use R-410A

compatible servicing equipment may result in property

damage or injury.

Wear safety glasses and gloves when handling

refrigerants. Failure to follow this warning can cause

serious personal injury.

R

G

W

R

G

Y

1

Y

W

2

W

1

Y/Y

2

** = Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

SINGLE STAGE

THERMOSTAT

UNIT CONTROL BOARD

TERMINAL STRIP

24 VOLT

TRANSFORMER

* *

NOTE: HEAT ANTICIPATOR

SHOULD BE SET AT 0.35

AMPS FOR ALL MODELS.

C

C

PROGRAMMABLE

THERMOSTAT ONLY

JUMPER NEEDED FOR FULL SPEED

COMPRESSOR OPERATION