288591-BIM-C-0408

Johnson Controls Unitary Products

17

Blower Speed Selection

The variable speed blowers are designed to deliver constant

CFM regardless of the external static pressure (ESP) in the

ductwork. Therefore, if too many supply registers are closed, a

filter becomes clogged, or there is a restriction in the ductwork,

the motor will automatically operate at a higher speed to

compensate for the higher ESP. This may result in a higher

operating sound level.

These units have variable speed motors that automatically

adjust to provide constant CFM from 0.2" to 0.6" w.c. static

pressure. From 0.6" to 1.0" static pressure, CFM is reduced by

2% per 0.1" increase in static. Operation on duct systems with

greater than 1.0" w.c. external static pressure is not

recommended.

To Set Cooling CFM:

Refer to Tables 7 and 8 for the possible cooling and heating

CFM selections.

Find the recommended system airflow for the unit model.

Set desired cooling airflow by moving the jumper on the “Cool”

tap located on the CFM selection board as indicated in Tables

7, 8 and Figure 10.

Airflow may be increased by 10% by moving the “ADJ” jumper

to “B”. Airflow may be decreased by 10% by moving the “ADJ”

jumper to “C”.

NOTE:

CFM indicator light flashes once for every 100 CFM

(i.e., 12 flashes = 1200 CFM).

To Set Delay Profile:

Every unit has multiple cooling “blower off delay” profiles to

optimize system performance and efficiency. Refer to Table

19 for the regional climate in your area. Place the “DELAY”

jumper tap on the CFM selection board to the appropriate pin

setting.

To Set Electric Heat CFM:

The airflow required for Electric Heat may be different than for

cooling.

Refer to Table 10 for the minimum required CFM for the

electric heater installed. Find the desired airflow in Tables 7

and 8. Set the “Heat” Jumper on the CFM selection board to

tap shown.

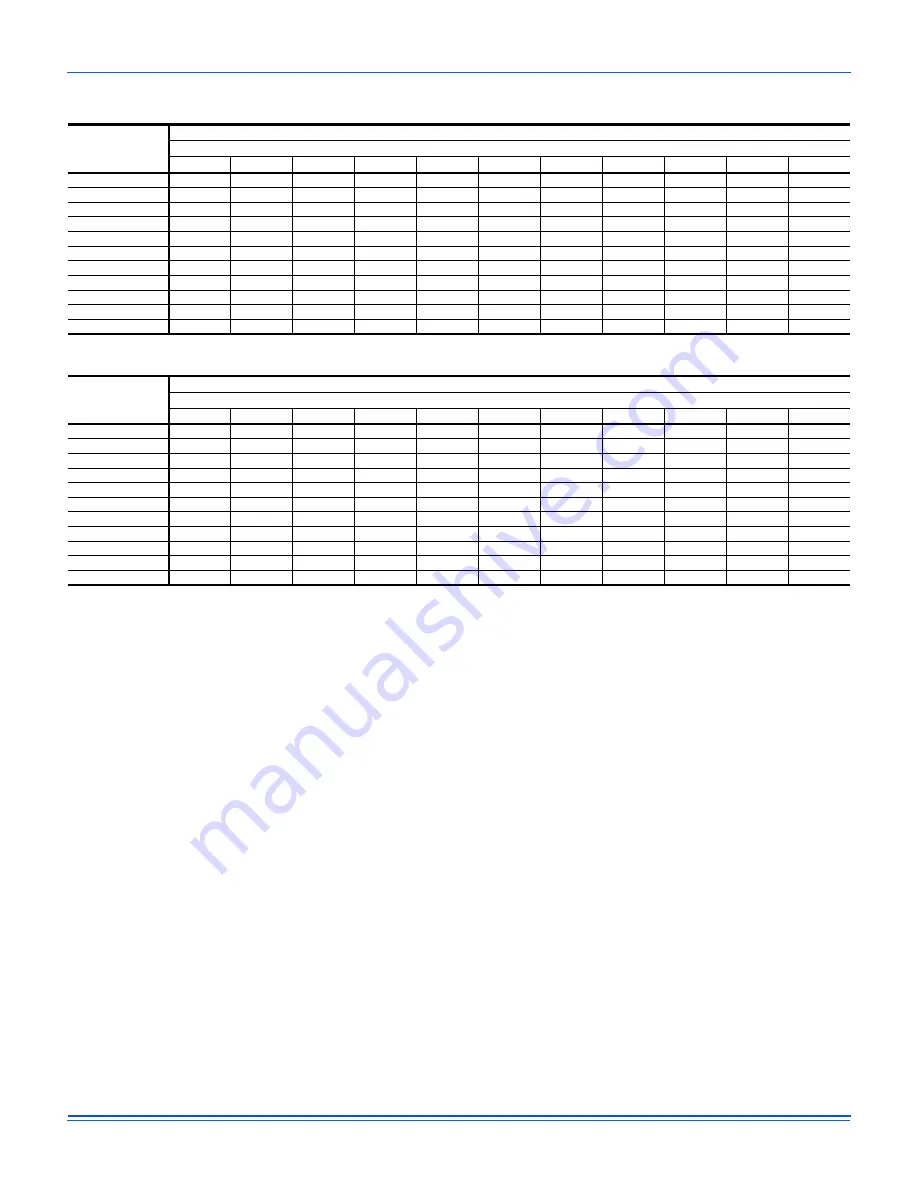

Table 17: DPX048 Superheat Charging

Outdoor

Temp

(°F)

Superheat at Compressor Suction (°F), Airflow = 1600 CFM

Indoor Wet Bulb Temp (°F)

55

57

59

61

63

65

67

69

71

73

75

65

10.1

10.0

9.9

9.8

9.8

9.7

9.6

9.6

9.7

9.7

9.7

70

9.9

9.8

9.7

9.7

9.6

9.5

9.5

9.5

9.6

9.6

9.6

75

9.7

9.6

9.5

9.5

9.4

9.4

9.3

9.4

9.5

9.5

9.5

80

9.5

9.4

9.4

9.3

9.3

9.2

9.2

9.3

9.4

9.4

9.5

85

9.2

9.2

9.2

9.1

9.1

9.0

9.0

9.1

9.2

9.3

9.4

90

8.8

8.9

8.9

8.9

9.0

9.0

9.1

9.2

9.4

9.5

9.5

95

8.4

8.5

8.6

8.7

8.9

9.0

9.1

9.3

9.5

9.6

9.7

100

8.3

8.4

8.5

8.6

8.7

8.8

9.0

9.2

9.5

9.7

9.8

105

8.3

8.4

8.4

8.5

8.6

8.7

8.8

9.2

9.5

9.7

9.9

110

8.2

8.3

8.4

8.4

8.5

8.6

8.7

9.1

9.5

9.8

10.0

115

8.1

8.2

8.3

8.3

8.4

8.4

8.5

9.0

9.5

9.8

10.1

Table 18: DPY060 Superheat Charging

Outdoor

Temp

(°F)

Superheat at Compressor Suction (°F), Airflow = 1750 CFM

Indoor Wet Bulb Temp (°F)

55

57

59

61

63

65

67

69

71

73

75

65

16.6

16.7

16.8

16.9

17.1

17.2

17.3

17.9

18.4

18.7

19.0

70

16.2

16.4

16.5

16.6

16.7

16.8

17.0

17.4

17.9

18.1

18.4

75

15.9

16.0

16.1

16.2

16.4

16.5

16.6

17.0

17.4

17.6

17.7

80

15.5

15.7

15.8

15.9

16.0

16.1

16.3

16.5

16.8

17.0

17.1

85

15.2

15.3

15.4

15.5

15.7

15.8

15.9

16.1

16.3

16.4

16.5

90

14.0

14.2

14.3

14.4

14.5

14.6

14.8

15.3

15.9

16.2

16.5

95

12.9

13.0

13.1

13.2

13.4

13.5

13.6

14.6

15.5

16.0

16.5

100

12.6

12.8

12.9

13.0

13.1

13.2

13.3

14.3

15.2

15.7

16.2

105

12.4

12.5

12.6

12.7

12.8

12.9

13.0

14.0

14.9

15.4

15.9

110

12.2

12.3

12.3

12.4

12.5

12.6

12.7

13.7

14.6

15.1

15.6

115

11.9

12.0

12.1

12.2

12.2

12.3

12.4

13.4

14.3

14.8

15.3