JOHNSON CONTROLS

14

FORM 145.32-IOM1 (908)

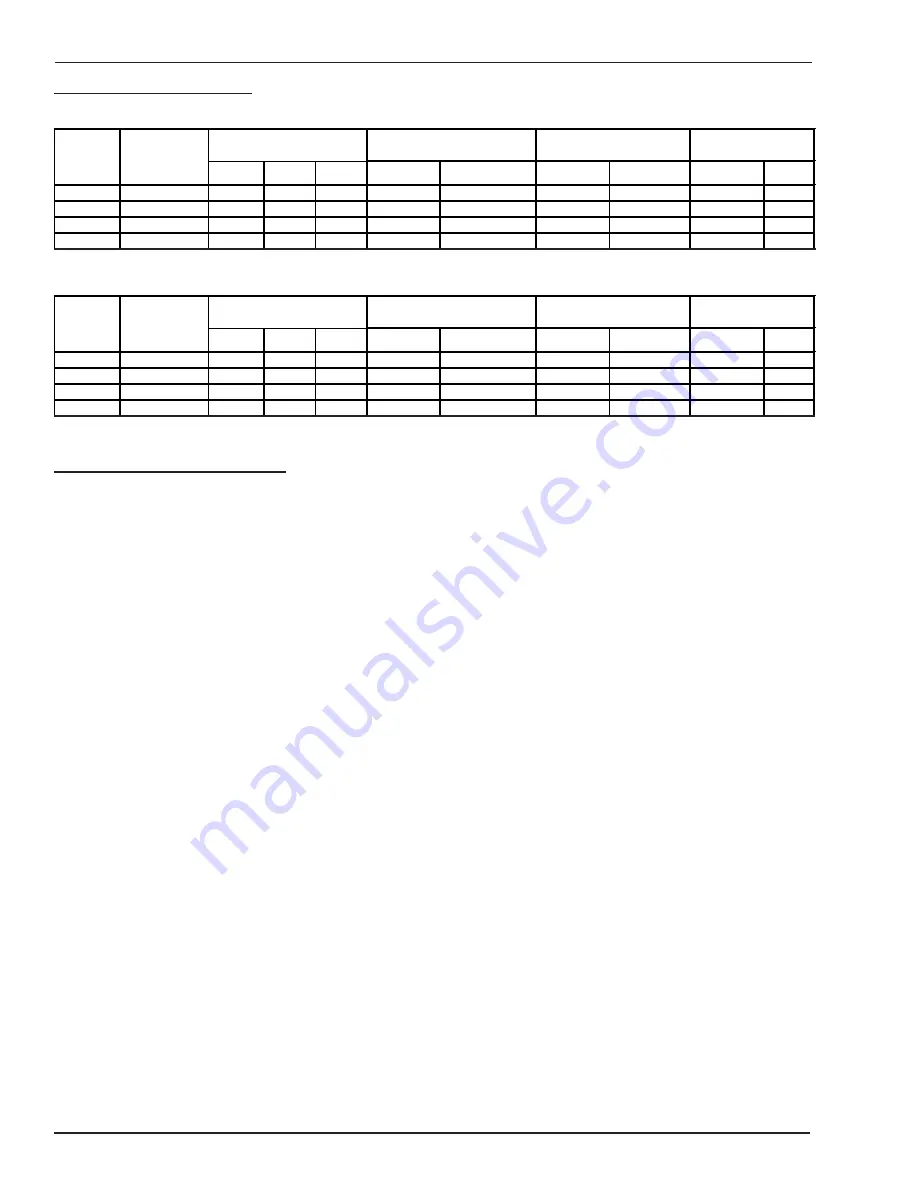

MOTOR AND PULLEY DATA

EVAPORATOR

- STANDARD BLOWER MOTOR AND DRIVE DATA

Belts

HP

Frame Eff.(%)

Pitch Dia.(in)

Browning #

Pitch Dia.(in)

Browning#

Rating / Size

Qty

2 TON

845-1170

1/4

56

66.0

2.6-3.6

1VP40 X 5/8

5.4

AK56H

4L370

1

3 TON

675-1010

1/3

56

75.0

2.0-3.0

1VP34 X 5/8

5.2

AK54H

4L370

1

4 TON

675-1010

3/4

56

75.0

2.0-3.0

1VP34 X 5/8

5.2

AK54H

4L400

1

5 TON

745-1120

1

143

75.0

2.0-3.0

1VP34 X 7/8

4.7

AK49H

4L390

1

CONDENSER

- STANDARD BLOWER MOTOR AND DRIVE DATA

Belts

HP

Frame Eff.(%)

Pitch Dia.(in)

Browning #

Pitch Dia.(in)

Browning#

Rating / Size

Qty

2 TON

770-1070

1/2

56

75.0

2.6-3.6

1VP40 X 5/8

5.9

AK61H

4L500

1

3 TON

745-1071

3/4

56

82.5

2.0-3.0

1VP34 X 5/8

4.7

AK49H

4L390

1

4 TON

615-920

1

143

82.5

2.0-3.0

1VP34 X 7/8

5.7

AK59H

4L490

1

5 TON

770-1070

1.5

145

84.0

2.6-3.6

1VP40 X 7/8

5.9

AK61H

4L500

1

Model

Motor

Adjustable

Motor Pulley

Model

Drive Range

(RPM)

Fixed

Blower Pulley

Drive Range

(RPM)

Motor

Adjustable

Motor Pulley

Fixed

Blower Pulley

BLOWER SPEED ADJUSTMENT

The RPM of the supply air and condenser air blow-

ers will depend on the required CFM, and the static

resistance of both the supply/discharge and the return/

intake duct systems. With this information, the RPM

for the blowers can be determined from the blower

performance tables. Adjustment of blower speed is

accomplished as follows:

1. Loosen belt tension by moving motor towards the

blower shaft via the adjustable mounting base.

2. Loosen the setscrew in the adjustable motor pul-

ley flange. Remove external key on pulleys 4-in.

dia and larger.

3. Blower speed will increase when moveable flange is

adjusted towards the fixed flange (closed). Blower

speed will decrease when the moveable flange

is adjusted away from the fixed flange (opened).

Pulleys are adjustable only in half-turn increments.

Do not open pulley more than five full turns for “4L”

and “A” belts, or six full turns for “B” belts.

4. Once the pulley has been opened/closed the ap-

propriate number of turns, replace the external key

and tighten the adjustment set screw. Proper torque

is 110 - 130 in-lbs.

5. Install drive belt and adjust motor mount to tension

belt.

Summary of Contents for DSH

Page 5: ...FORM 145 32 IOM1 908 5 Johnson Controls TYPICAL INSTALLATION DRAWING ...

Page 9: ...FORM 145 32 IOM1 908 9 Johnson Controls DIMENSIONAL DATA ...

Page 10: ...JOHNSON CONTROLS 10 FORM 145 32 IOM1 908 DIMENSIONAL DATA Cont ...

Page 16: ...JOHNSON CONTROLS 16 FORM 145 32 IOM1 908 TYPICAL SCHEMATIC ...