4

3.

Use a portable vacuum with HEPA filtration to re

-

move the loose dirt and organic matter. The filter

should be 99.97% efficient at .3 micron particle

size.

4. If no microbial growth (mold) exists, thoroughly

clean the fan and associated components with an

industrial cleaning solution. Carefully follow the

cleaning solution manufacturer instructions re-

garding use and disposal of their product.

5. If microbial growth (mold) is present remove the

contamination, and thoroughly clean the affected

area with an EPA-approved sanitizer specifically

designed for HVAC use. Carefully follow the san-

itizer manufacturer instructions regarding the use

and disposal of their product.

6. Rinse the affected surfaces thoroughly with fresh

water and a fresh sponge to prevent potential cor-

rosion of metal surfaces.

7. Allow the unit to dry completely before putting it

back into service.

8. Use caution to assure that any contaminated ma-

terial does not contact other areas of the unit or

building.

Properly dispose of all contaminated ma-

terials and cleaning solutions.

Important: If the microbial growth (mold)

was found, the cause of the contamination

must be determined and action taken to

assure it does not reoccur.

Fan Bearings

Bearing Set Screw Alignment

Align bearing setscrews. See

for

bearing setscrew torque.

Fan Bearings should be lubricated with a lithium base

grease which conforms to NLGI Number 2 for consis-

tency. See

Table 2 on page 23, Table 3 on page 23,

for recommended greasing

intervals, operating range, and bearing grease capacities.

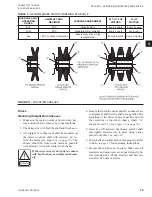

TABLE 2 -

RECOMMENDED GREASING

INTERVALS OF FAN BEARINGS

OPERATING

CONDITIONS

-20°F TO

+140°F

140°F TO

200°F

Clean, Dry

3-6 months

1-3 weeks

Dirty, Dry

1-3 months

1-4 weeks

Dirty, Wet, High Humid

1-4 weeks

1-14 days

TABLE 3 -

RECOMMENDED GREASES FOR VARI-

OUS OPERATING RANGES

RECOMMENDED

GREASES

RECOMMENDED OPER-

ATING RANGE

Texaco-Multi Fak #2

-20°F to +250°F

Shell Alvania #2

-20°F to +250°F

Mobil Mobilux #2

-20°F to +250°F

Exxon Unirex #2

-20°F to +250°F

Exxon Beacon

-65°F to +250°F

TABLE 4 -

FAN BEARING MAXIMUM GREASE

CAPACITY

SHAFT SIZE IN INCHES

CAPACITY IN FL. OZ.

1/2 – 3/4

1/8

7/8 – 1-3/16

3/8

1-1/4 – 1-1/2

5/8

1-11/16 – 1-15/16

7/8

2 – 2-7/16

1-1/4

2-1/2 – 2-15/16

2

Lubricating the Fan Bearing

To lubricate the fan bearing, complete the following:

1. Disconnect all electrical power to the unit, tag and

lock out power source.

2. Check grease lines for tight connections at the

grease fitting.

3. Using a manual low-pressure grease gun, add

grease until a light bead appears at the bearing

grease seal. Turn the fan wheel manually while

adding grease.

Motor

General Inspection

Inspect the motor at regular intervals, approximately

every 500 hours of operation or every three months,

which ever occurs first. Operating conditions will vary

the frequency of inspection and lubrication. Table

5 (

lists recommended motor

JOHNSON CONTROLS

23

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013