which will be handling 35ºF, or colder, air.

The desired degree of control can be obtained

with a modulating valve on the downstream

coil.

d. Provision should always be made to thor-

oughly mix fresh air and return air before it

enters the coil. In addition, temperature con-

trol elements must be properly located to ob-

tain true air mixture temperatures.

e. As additional protection against freeze-up,

the trap should be installed sufficiently be-

low coil to provide an adequate hydrostatic

head to ensure removal of condensate during

an interruption in the steam pressure. Esti-

mate 3 feet for each 1-psi of trap differential

required.

f. On startup, admit steam to coil ten minutes

before admitting outdoor air.

g. Provision must be made to close fresh air

dampers if steam supply pressure falls below

minimum specified.

Water Heating Coils

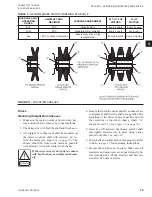

1. Water supply and water return connections extend

through the end panel of the coil section. All con-

nections are labeled on the end panel.

2. Water supply and water return connections are

male N.P.T copper pipe.

3. When installing couplings, do not apply undue

stress to the connection extending through unit

panel. Use a backup pipe wrench to avoid break-

ing the weld between coil connection and header.

4. Follow recommendations of the control manu-

facturer regarding types, sizes and installation of

control valves.

5. Hot water coils are not recommended for use with

entering air below 40ºF.

6. If fresh air and return air are to be heated by a hot

water coil, care should be used in the design of

the system to assure thorough mixing before air

enters the coil.

JOHNSON CONTROLS

32

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE