4

TABLE 5 -

RECOMMENDED MOTOR GREASING SCHEDULE

AVERAGE DAILY

OPERATING

HOURS

AMBIENT TEMP.

MAXIMUM

AVERAGE ENVIRONMENT

.25 TO 7.5 HP

MOTORS

10 HP

MOTORS

8-16

40°C

Clean and Dry

Every 5 years

Every 3 years

12-24

50°C

Moderate Dirt or Moisture

Every 2 years

Every year

Any

>50°C or Class H Insulation

Severe (very dirty or high

temperatures)

Every 6 months Every 3 months

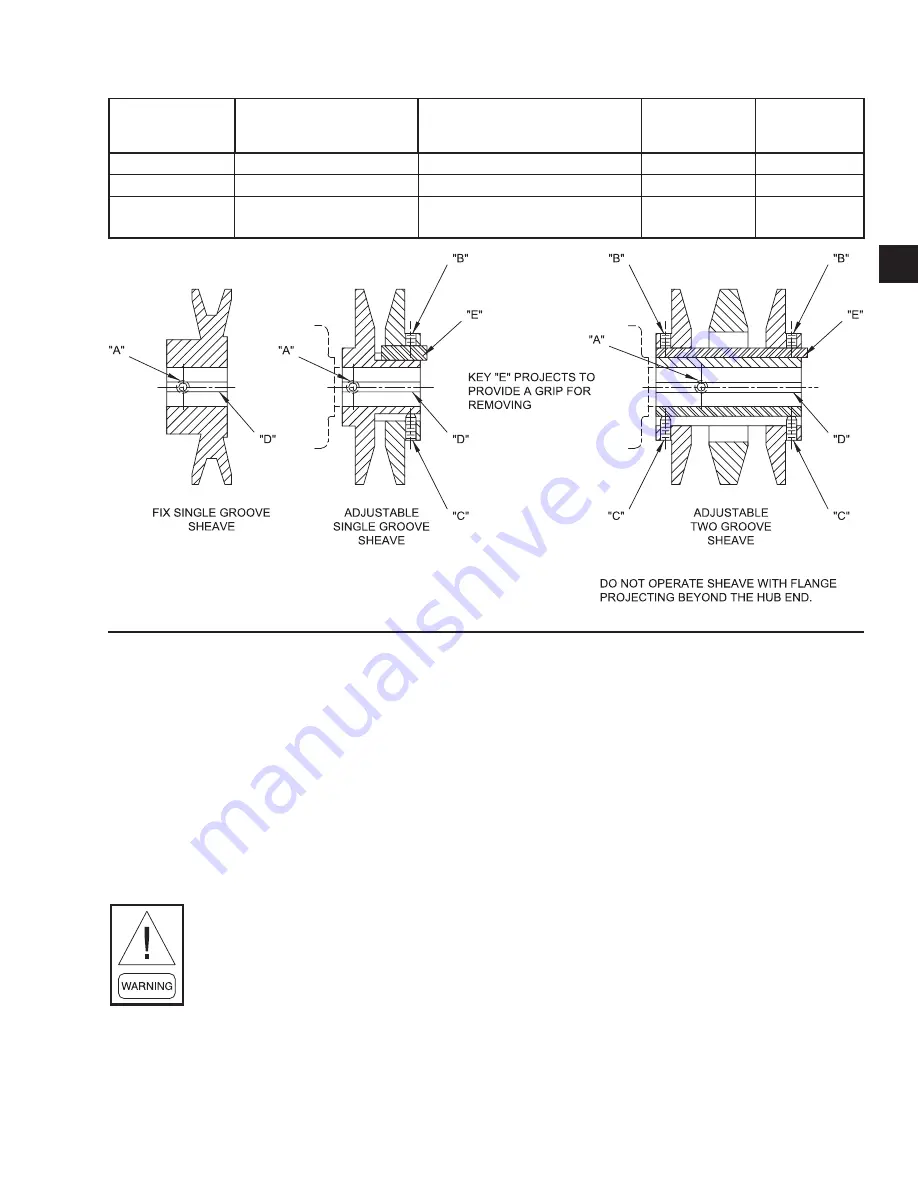

FIGURE 11 -

MOUNTING SHEAVES

Drives

Mounting Straight Bore Sheaves

1. Make sure there are no nicks or burrs on key, key-

way and shaft. If so, remove by proper methods.

2. Check key size with both the shaft and the sheave.

3. All straight bore sheaves should be mounted on

the motor or driver shaft with setscrew (A) to-

sheave should be close to the motor as possible

with setscrew (A) in full contact with the key.

If the setscrew (a) is not fully in contact

with key, the sheave assembly could come

off.

4. Be sure that both the driver and driven sheaves are

in alignment and that the shafts are parallel. The

centerline of the driver sheave must line up with

the centerline of the driven sheave. Angle “A”

5. Insert key (D) between the sheave and the shaft

and tighten setscrew (A) in place using torque

.

6. Put on belts and adjust belt tension properly. Refer

for tensioning instructions.

7. Be sure that all keys are in place. Make sure all

setscrews and capscrews are torqued properly be-

fore starting drive. Check setscrew and belt ten-

sion after 24 hours of service.

JOHNSON CONTROLS

25

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013