2

F59D Technical Bulletin

To install weights and cable

proceed as follows:

!

CAUTION: Do not drop

weights. The weights could

crack causing them to

waterlog. This would

prevent the switch from

operating automatically and

would require a new weight

kit.

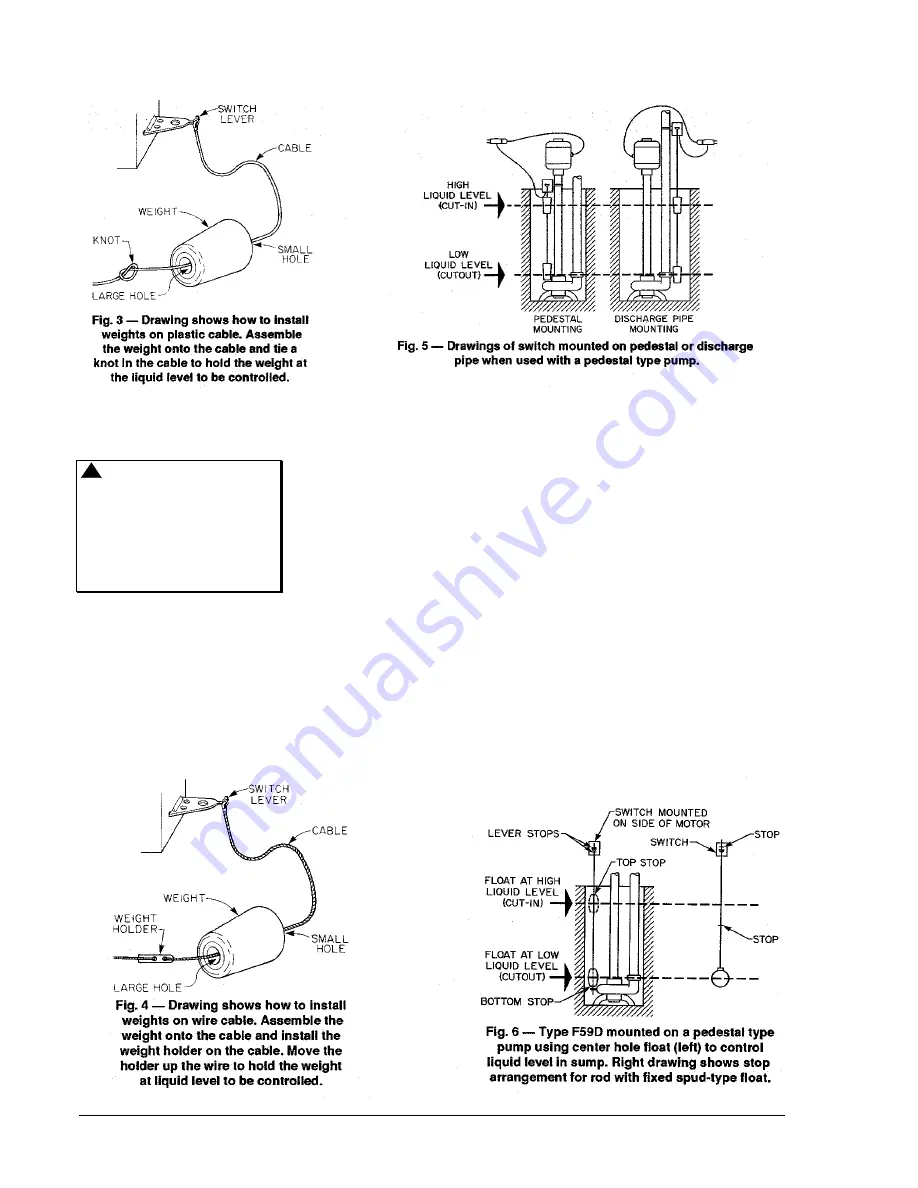

For Plastic Cable

1.

Place the cable eyelet over

the hook on the switch

lever. Do not crimp or bend

the switch lever hook.

2.

Thread upper weight onto

plastic cable with large hole

down.

3.

Determine upper liquid level

(pump turn-on level) and tie

a knot in the plastic cable to

support weight at the

selected liquid level. (See

Fig. 3.)

4.

Slide the weight down over

the knot.

5.

Thread lower weight onto

plastic cable.

6.

Determine lower liquid level

(pump turnoff level) and tie

a knot in plastic cable to

support weight at the

selected liquid level.

7.

Slid the weight down over

the knot.

8.

Cut off excess cable below

lower weight after checking

to be sure weights are at

the correct level. (See

Fig. 2.)

For Wire Cable

1.

Place the cable eyelet over

the hook on the switch

lever. Do not crimp or bend

the switch lever hook.

2.

Thread upper weight onto

wire cable.

3.

Thread upper weight holder

onto wire cable to support

weight at the selected liquid

level. (See Fig. 4.)