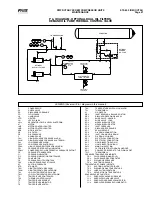

RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 29

Figure 25

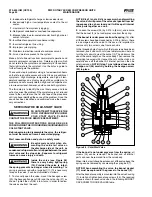

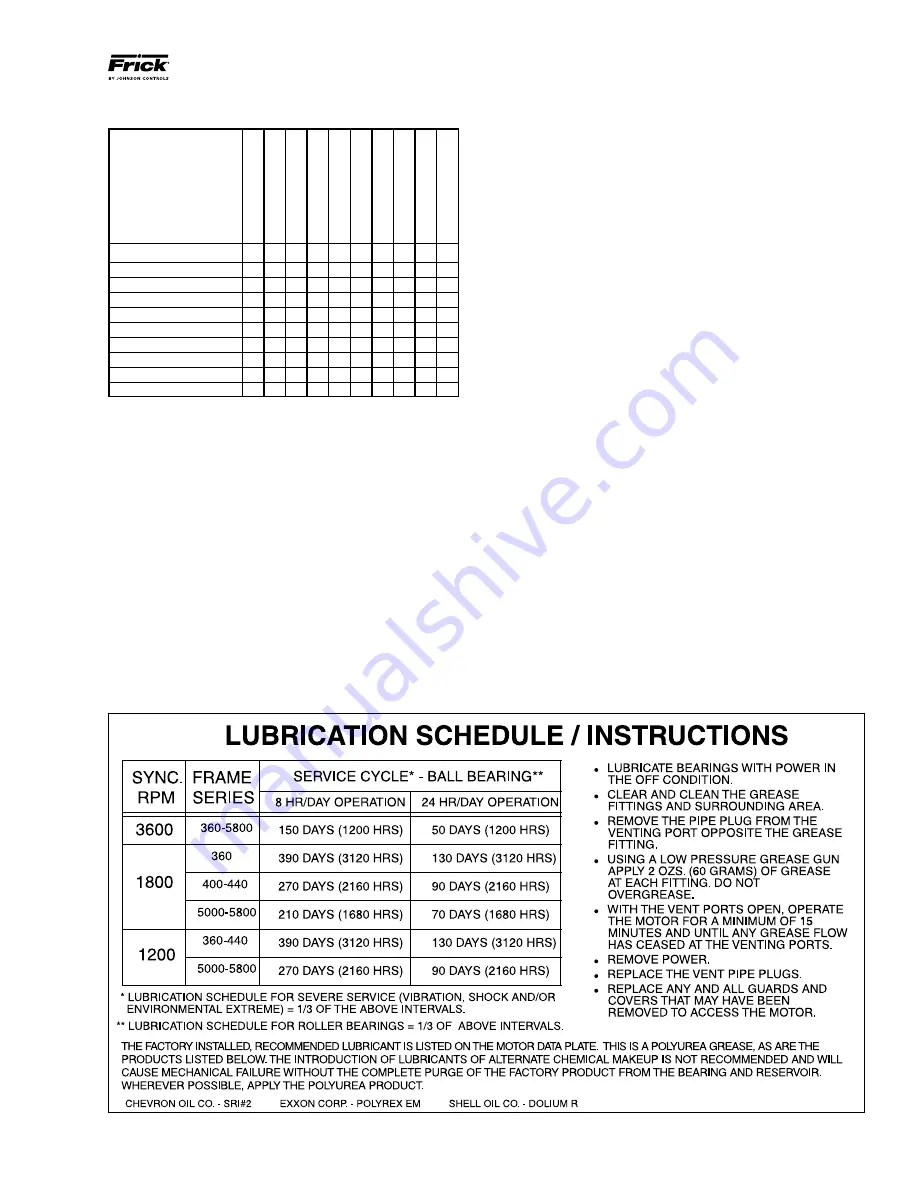

Aluminum Complex

– I

I C I

I

I

I C I

Barium

I – I C I

I

I

I

I

I

Calcium

I

I – C I C C B C I

Calcium 12-hydroxy

C C C – B C C C C I

Calcium Complex

I

I

I B – I

I

I C C

Clay

I

I C C I – I

I

I

I

Lithium

I

I C C I

I – C C I

Lithium 12-hydroxy

I

I B C I

I C – C I

Lithium Complex

C I C C C I C C – I

Polyurea*

I

I

I

I

C

I

I

I

I –

B = Borderline Compatibility

C = Compatible

I = Incompatible

* Standard

Alumin

um Comple

x

Bar

ium

Calcium

Calcium 12-h

ydro

xy

Calcium Comple

x*

Cla

y

Lithium

Lithium 12-h

ydro

xy

Lithium Comple

x

P

olyurea

NLGI Grease Compatibility Chart

TROUBLESHOOTING GUIDE

Successful problem solving requires an organized ap proach

to define the problem, identify the cause, and make the proper

correction. Sometimes it is possible that two relatively obvi-

ous problems combine to provide a set of symptoms that can

mislead the troubleshooter. Be aware of this possibility and

avoid solving the “wrong problem”.

ABNORMAL OPERATION

ANALYSIS and CORRECTION

Four logical steps are required to analyze an opera tional

problem effectively and make the necessary correc tions:

1.

Define the problem and its limits.

2.

Identify all possible causes.

3.

Test each cause until the source of the problem is found.

4.

Make the necessary corrections.

The first step in effective problem solving is to define the

limits of the problem. If, for example, the compressor peri-

odically experiences high oil tempera tures, do not rely on

this observation alone to help identify the problem. On the

basis of this information the apparent corrective measure

would appear to be a readjustment of the liquid injection

system. Lowering the equalizing pres sure on the thermal

expansion valve would increase the refriger ant feed and the

oil temperature should drop.

If the high oil temperature was the result of high suction

superheat, however, and not just a matter of improper liquid

injection adjustment, increasing the liquid feed could lead to

other problems. Under low load conditions the liquid injection

system may have a tendency to overfeed. The high suction

superheat condition, moreover, may only be temporary. When

system conditions return to normal the units’ liquid injection

will overfeed and oil temperature will drop. In solving the

wrong problem a new problem was created.

When an operating problem develops compare all operat ing

information on the MAIN OPERATING SCREEN with normal

operating conditions. If an Operating Log has been main-

tained the log can help determine what constitutes normal

operation for the compressor unit in that particular system.

The following list of abnormal system conditions can cause

abnormal operation of the RWF compressor unit:

1.

Insufficient or excessive refrigeration load.

2.

Excessively high suction pressure.

3.

Excessively high suction superheat.

4.

Excessively high discharge pressure.