RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 30

5.

Inadequate refrigerant charge or low receiver level.

6.

Excessively high or low temperature coolant to the oil

cooler.

7.

Liquid return from system (slugging).

8.

Refrigerant underfeed or overfeed to evaporators.

9.

Blocked tubes in water-cooled oil cooler from high mineral

content of water.

10.

Insufficient evaporator or condenser sizing.

11.

Incorrect refrigerant line sizing.

12.

Improper system piping.

13.

Problems in electrical service to compressor unit.

14.

Air and moisture present in the system.

Make a list of all deviations from normal plant operation and

normal compressor unit operation. Delete any items which

do not relate to the symptom and separately list those items

that might relate to the symptom. Use the list as a guide to

further investi gate the problem.

The second step in problem solving is to decide which items

on the list are possible causes and which items are additional

symptoms. High discharge temperature and high oil tem-

perature readings on a display may both be symptoms of a

problem and not casually relat ed. High suction superheat or

a low receiver level, however, could cause both symptoms.

The third step is to identify the most likely cause and take

action to correct the problem. If the symptoms are not relieved

move to the next item on the list and repeat the procedure

until you have identified the cause of the problem. Once the

cause has been identi fied and con firmed make the neces-

sary correc tions.

SERVICING THE COLD-START VALVE

DO NOT ATTEMPT TO SERVICE THE

YORK REFRIGERatIOn/GRam

COLD START VALVE. PLEASE

CONTACT THE FRICK SERVICE DEPARTMENT.

THE FOLLOWING INSTRUCTIONS SHOULD BE USE

FOR SURVICING THE

YORK REFRIGERatIOn/DanFOSS

COLD-START VALVE.

Before beginning to disassemble the valve, the refriger-

ant must be removed from all associated piping.

Start room ventilation and put on a safety mask.

Be extremely careful when dis-

mantling the cold-start valve on

the discharge side of the unit, as

condensed refrigerant often is trapped between the cold-

start valve and the stop valve. Exposure to refrigerant

fumes can cause injury or death.

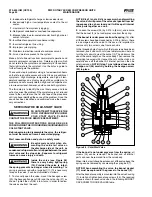

Inside the valve (see Figure 28)

there is a very heavy, tight spring

(15). Provided the valve is intact,

the spring presents no danger when dismantling.

The

spring is compressed with a large bolt (7). If it is necessary

to repair the valve, it can be dismantled as follows:

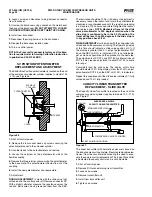

1.

To manually open the valve, mount the hexagon screw

(29), the hexagon flange nut (28) and the nylon ring (27) as

shown. Tighten the nut (28) a few turns, in order to redraw

the valve cone from the seat.

NOTE: Step 1 is not strictly necessary when dismantling

the valve, but will prevent the valve seat gasket from be-

ing exposed to a shear load, and it will keep all internal

valve parts together as a unit.

2.

Loosen the screws (24) by 0.315 in (8 mm), and ensure

that the bonnet (2) is not under pressure from the spring.

If the bonnet is under pressure from the spring

(15) after

all the screws have been loosened by 0.315 in (8 mm), there

is a damage inside the valve. In this case, it is important to

remove only two screws, one from each side.

In the threaded holes from which the two screws have been

removed, insert studs with nuts (see table for screw size) and

turn the nuts down to meet the bonnet (2). The studs must be

about the same length as the valve body. Then remove the

remaining two screws (24), loosen the nuts on the studs, and

carefully ease off the bonnet. All internal parts can then be

safely removed.

NOTE: If step 1 was followed, loosen the

hexagon nut (28) carefully, holding the hexagon screw

(29) in place.

Figure 28 - Cold-Start Valve

If the bonnet is not under pressure from the spring

, all

screws (24) can be removed. The bonnet and all internal

parts can now be removed from the valve body.

When internal parts have been taken out of the valve body, the

spring can be removed by unscrewing the spring bolt (7).

NOTE: When assembling the valve, the bonnet gasket

(17) must be captured in the groove in the bonnet (2).

After the bonnet assembly is mounted into the valve housing

(1), install and tighten bonnet cap screws (24). The required

torque is shown for each valve size in the following BONNET

CAP SCREW TORQUE VALUES table.