RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 31

PRESSURE TRANSDUCERS - TESTING

1.

Shut down the compressor and allow pressures to

equalize.

2.

Isolate suction transducer PE-4 from the unit and depres-

surize.

NOTE: Recover or transfer all refrigerant vapor,

in accordance with local ordinances, before opening to

atmosphere.

3.

Measure the voltage of PE-4 on connector P4 (terminals

WHT and BLK) on the SBC with a digital voltmeter.

4.

The voltage reading should be 1.48 VDC to 1.72

VDC at standard atmospheric pressure (14.7 PSIA or 0

PSIG). When checking transducers at higher elevations, an

allowance in the readings must be made by subtracting ap-

proximately 0.02 VDC per 1000 feet of elevation above sea

level. Therefore, if PE-4 is measured at 5000 feet elevation

under relatively normal weather conditions, the output volt-

age should differ by 0.10 VDC to read between 1.38 VDC

and 1.62 VDC.

5.

Isolate the oil pressure transducer PE-1 from the

package and open it to atmosphere.

6.

Measure the voltage of PE-1 on connector P4

(terminals WHT and BLK) on the SBC.

7.

The voltage reading should be between 1.1 VDC

and 1.29 VDC at standard atmospheric pressure. PE-1, PE-2,

and PE-3 all have a span of 500 PSI as compared to PE-4

with a span of 200 PSI. Therefore, atmospheric pressure

changes have a lesser effect which is 0.0067 VDC per 1000

feet of elevation and 0.00067 VDC per 0.1 inch Hg barometric

deviation.

8.

Isolate transducer PE-2 from the package and

depressurize.

NOTE: Recover or transfer all refrigerant

vapor, in accordance with local ordinances, before open-

ing to atmosphere.

9.

Measure the voltage of PE-2 on connector P4 (terminals

WHT and BLK) on the SBC.

10.

The voltage reading should be between 1.1 VDC and

1.29 VDC at standard atmospheric pressure (see Step 12).

11.

Since the discharge pressure, PE-3, cannot be closed

off from its sensing point (code require ments), close all

transducers from atmosphere and open them to their sens-

ing points so all transducers can equalize to separator pres-

sure.

12.

Measure the voltage of PE-3 on connector P4 (terminals

WHT and BLK) on the SBC.

13.

Measure the voltage of PE-1 on connector P4 (terminals

WHT and BLK) on the SBC.

14.

These two voltages should be within .04 VDC of one

another.

15.

Test is complete.

PRESSURE TRANSDUCERS - REPLACEMENT

1.

Shut off control power.

2.

Close the applicable transducer isolation valve.

NOTE:

To change the discharge pressure transducer (PE-3), it

will be necessary to depressurize the entire compressor

package. Follow "General Instructions For Replacing

Compressor Unit Components" before going to step 3.

3.

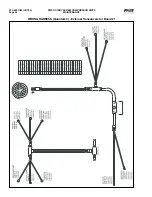

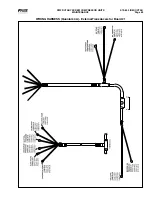

Refer to the WIRING HARNESS section, External

Transducers for Board #1, to identify the wiring harness

connectors.

*

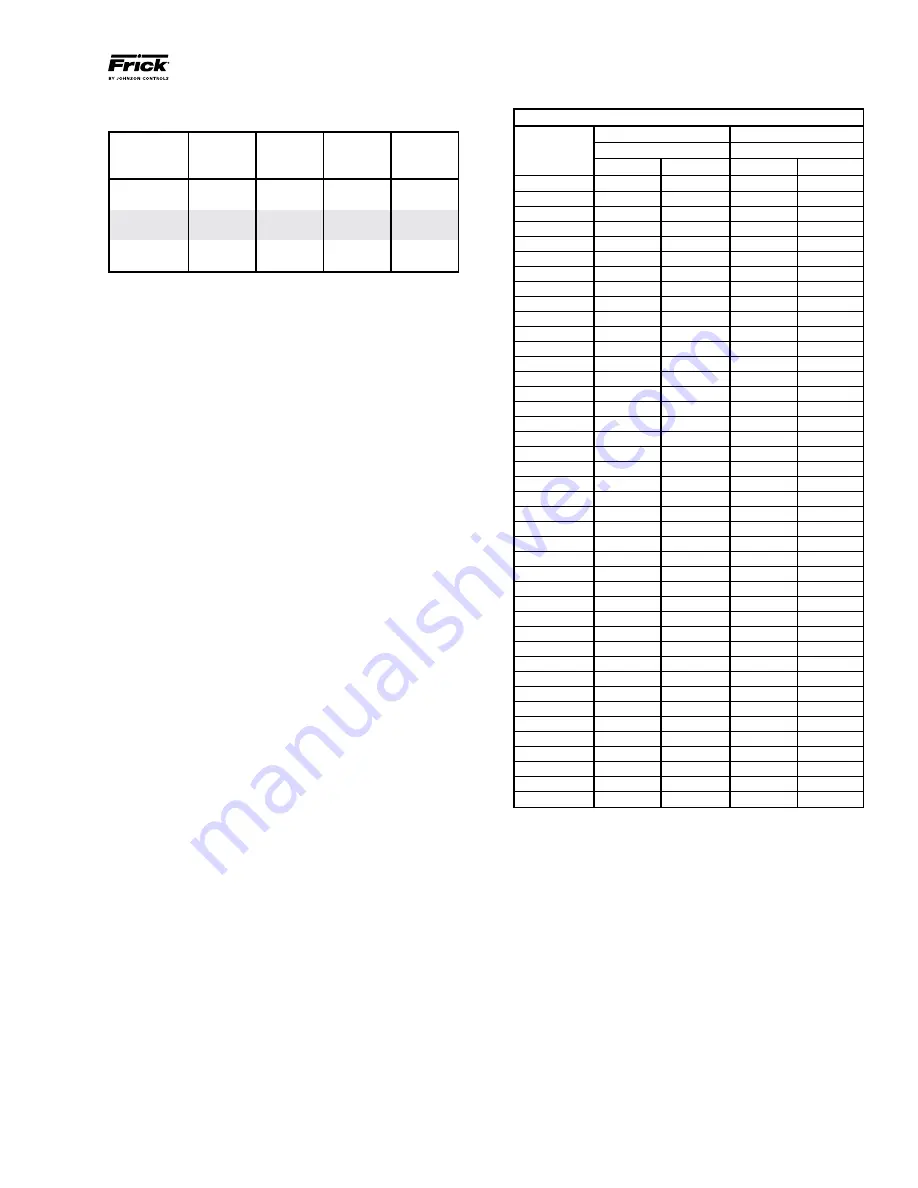

Below 0 PSIG measured in inches of mercury.

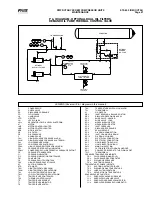

PRESSURE TRANSDUCER CONVERSION DATA

200 psi

500 psi

Sensor

Range - PSI

Range - PSIG*

Voltage

low

high

low

high

1.0

29.92"

9.57"

29.92"

4.10

1.1

29.92"

0.30

29.92"

16.60

1.2

29.92"

5.30

17.10"

29.10

1.3

19.74"

10.30

4.10

41.60

1.4

9.57"

15.30

16.60

54.10

1.5

0.30

20.30

29.10

66.60

1.6

5.30

25.30

41.60

79.10

1.7

10.30

30.30

54.10

91.60

1.8

15.30

35.30

66.60

104.10

1.9

20.30

40.30

79.10

116.60

2.0

25.30

45.30

91.60

129.10

2.1

30.30

50.30

104.10

141.60

2.2

35.30

55.30

116.60

154.10

2.3

40.30

60.30

129.10

166.60

2.4

45.30

65.30

141.60

179.10

2.5

50.30

70.30

154.10

191.60

2.6

55.30

75.30

166.60

204.10

2.7

60.30

80.30

179.10

216.60

2.8

65.30

85.30

191.60

229.10

2.9

70.30

90.30

204.10

241.60

3.0

75.30

95.30

216.60

254.10

3.1

80.30

100.30

229.10

266.60

3.2

85.30

105.30

241.60

279.10

3.3

90.30

110.30

254.10

291.60

3.4

95.30

115.30

266.60

304.10

3.5

100.30

120.30

279.10

316.60

3.6

105.30

125.30

291.60

329.10

3.7

110.30

130.30

304.10

341.60

3.8

115.30

135.30

316.60

354.10

3.9

120.30

140.30

329.10

366.60

4.0

125.30

145.30

341.60

379.10

4.1

130.30

150.30

354.10

391.60

4.2

135.30

155.30

366.60

404.10

4.3

140.30

160.30

379.10

416.60

4.4

145.30

165.30

391.60

429.10

4.5

150.30

170.30

404.10

441.60

4.6

155.30

175.30

416.60

454.10

4.7

160.30

180.30

429.10

466.60

4.8

165.30

185.30

441.60

479.10

4.9

170.30

190.30

454.10

491.60

5.0

175.30

195.30

466.60

504.10

At 0 psig

1.094 V

1.494 V

0.968 V

1.268 V

BONNET CAP SCREW TORQUE VALUES

Valve

Valve

Screw

Size

Torque

Size

Torque

Size

DN (mm)

(Nm)

ANSI

(lb-ft)

(mm)

65

74

2 1/2"

54

M12

80

44

3"

32

M10

100

74

4"

54

M12

125

183

5"

134

M16

150

183

6"

134

M16

200

370

8"

271

M20