RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 32

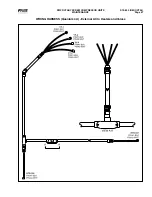

SV POSITION POTENTIOMETER

REPLACEMENT AND ADJUST MENT

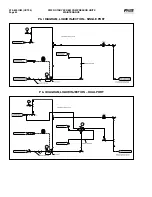

The Slide Valve Position potentiometer is located on the end

of the compressor unloader cylinder (applies to models 100

- 270), see Figure 26.

POTENTIOMETER

FLEXIBLE

COUPLING

COVER

LOCKNUT

Figure 26

1.

Shut off control power.

2.

Remove the four socket head cap screws securing the

potentiometer cover to the unloader cylinder.

3.

Unsolder leads to the potentiometer and remove.

4.

Loosen the setscrew on the potentiometer side of the

flexible coupling.

5.

Remove the three retainer clips securing the poten tiometer

to the base plate. The potentiometer should slip out of the

coupling.

6.

Install the new potentiometer and reassemble.

7.

Adjustment:

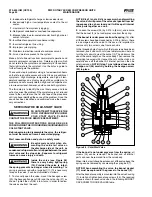

ROUGH ADJUSTMENT

is made with the slide valve fully

unloaded and the control power off. Remove connector P5.

With a digital voltmeter, measure the resistance across the

red and white wires, having removed them from the SBC.

The resistance should be 1000 +/- 50 ohms. If adjustment is

necessary, loosen the locknut and rotate the potentiometer

clockwise or counterclock wise until the resistance reading

is a close to a 1000 ohms as possible. Retighten the locknut

and replace wires.

NOTE: Mechanical travel of the slide

valve potentio meter is 300 degrees rotation when the

slide stop is confirmed to be in the 2.2 Vi position. The

travel will be less than 300 degrees if the slide stop is

in any position above 2.2 Vi.

FINE ADJUSTMENT

must be made with the slide valve fully

unloaded and the compressor running. The Operating display

at this time should indicate a slide valve position of 0%. If

the display is greater than 0%, adjust potentio meter POT

#4 on the SBC until 0% is indicated. If 0% is not attainable,

get as close as possible and then proceed to the next step.

The adjust ments of POT #4 and POT #3 are interactive and

POT #3 may require adjustment to allow POT #4 to come

into range.

Completely load the slide valve. The display at this time

should indicate 100%. If the display is less than 100%, adjust

potentiometer POT #3 on the SBC until 100% is indicated.

Repeat this sequence until the slide valve indicates 0% fully

unloaded and 100% fully loaded.

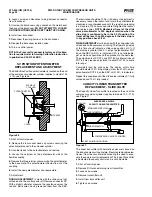

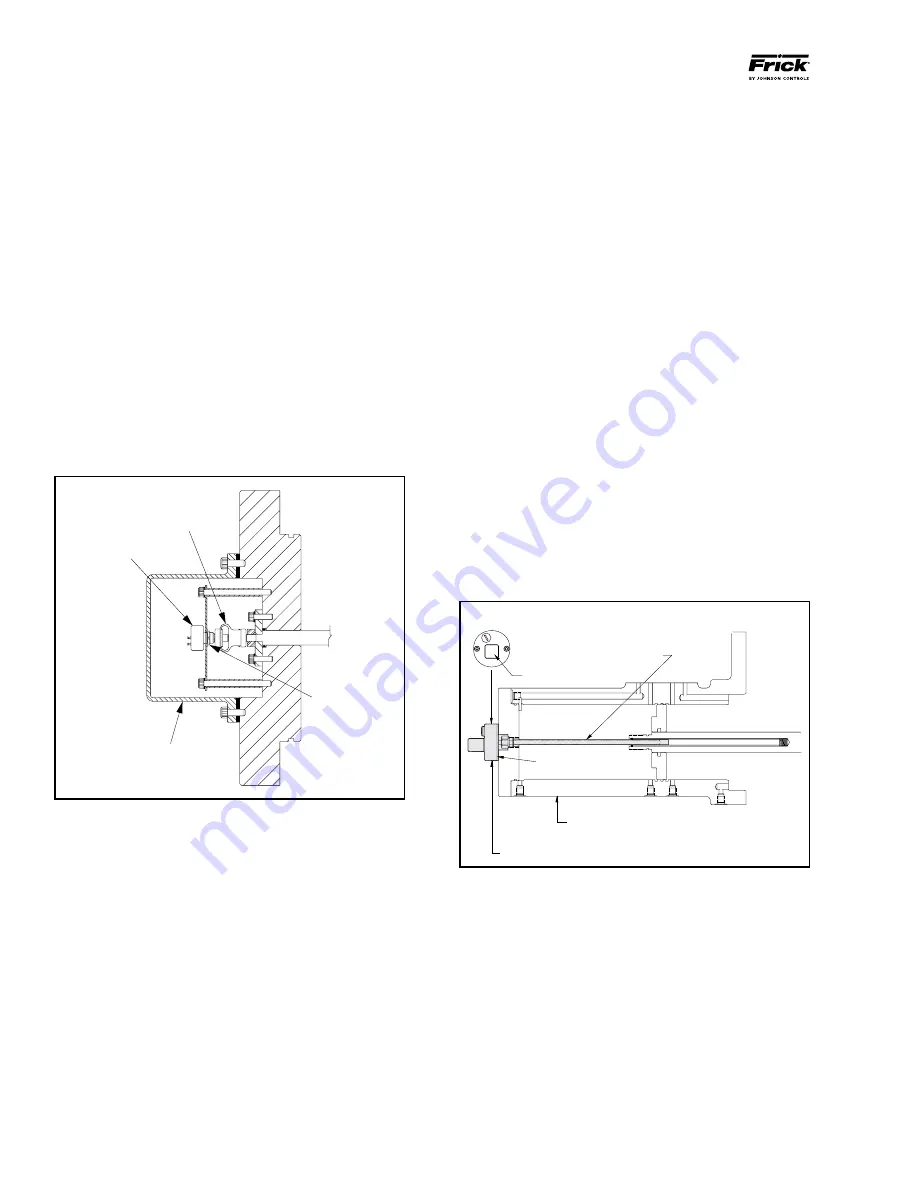

CAPACITY LINEAR TRANSMITTER

REPLACEMENT - SLIDE VALVE

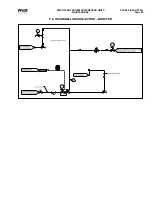

The Capacity Linear Transmitter is located on the end of the

compressor unload cylinder (applies to models 100 - 270),

see Figure 27.

END VIEW

DIN CONNECTOR

STAINLESS STEEL WELL

HEAT ISOLATOR

CAST ALUMINUM HOUSING

COMPRESSOR UNLOAD CYLINDER

SHADED AREA SHOWS

CAPACITY LINEAR TRANSMITTER

Figure 27

The linear transmitter with hermetic enclosure is based on

the inductive measuring principle. It features removable elec-

tronics (from the sensor well) eliminating the need to evac-

uate the compressor for replacement. This type of transmitter

is dedicated to capacity control and is not adjustable.

1.

Shut off control power.

2.

Remove DIN connector plug from transmitter.

3.

Loosen cap screws.

4.

Remove transmitter unit.

5.

Install new transmitter unit.

6.

Tighten cap screws.

4.

Loosen screw and disconnect wiring harness connector

from transducer.

5.

Unscrew the transducer using a wrench on the metal hex at

the base of the transducer.

DO NOT ATTEMPT TO LOOSEN

OR TIGHTEN TRANSDUCERS BY THEIR TOP CASING.

6.

Install new transducer.

7.

Reconnect the wiring harness to the transducer.

8.

Reopen the transducer isolation valve.

9.

Turn on control power.

NOTE: The Pressure Transducer is factory set. If calibra-

tion is required, refer to Amalog Calibration Instruction

in publication S90-010 M-ADD.