RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 39

SHUTDOWN DUE TO IMPROPER OIL

PRESSURE (HIGH STAGE and BOOSTER)

The compressor must not operate with incorrect oil

pressure.

1.

Refer to CONTROL SETUP - "OIL SETPOINTS DISPLAY"

in S90-010 O.

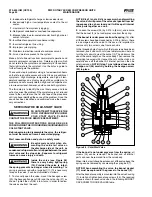

MOTOR REPLACEMENT

The following procedure is required when a motor is replaced

in the field.

1.

Verify that main power to the unit is disconnected and

tag the switch.

2.

Disconnect the coupling from the motor shaft.

3.

Remove the two bolts from the motor feet.

4.

While supporting the motor with a crane, remove the eight

bolts connecting the motor to the tunnel, then remove the

motor.

5.

Thoroughly clean the motor feet and mounting pads of

burrs and other foreign matter to ensure firm seating of the

new motor.

6.

While supporting the new motor with the crane, install and

hand tighten the eight bolts to connect the motor to the tunnel.

Then torque the bolts in a star pattern to 250 ft-lb.

7.

Then install the two bolts in the in the motor feet and torque

them to 250 ft-lb. Remove the crane from motor.

8.

Reattach coupling to the motor.

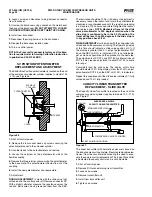

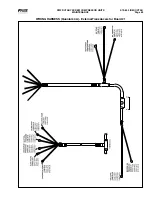

BARE COMPRESSOR REPLACEMENT

The following procedure is required only when a bare com-

pressor is replaced in the field.

1.

Verify that main power to the unit is disconnected and

tag the switch.

2.

Remove all tubing, piping, and wiring that is connected

to the compressor.

3.

Disconnect the coupling from the motor shaft.

4.

While supporting the motor and compressor assembly with

a crane, remove the bolts at the motor feet, compressor feet,

and separator flange.

5.

Thoroughly clean the compressor and motor feet and

mounting pads of burrs and other foreign matter to ensure

firm seating of the compressor.

6.

Clean the discharge flange surfaces on the compres sor

and separator.

7.

Set the assembly on a clean surface and remove the two

pins and bolts connecting the compressor to the tunnel and

remove the compressor.

8.

Assemble the new compressor to the tunnel by inserting

the two pins and hand tightening the bolts. then torque the

bolts in a star pattern to 250 ft-lb.

9.

Install a gasket on the compressor discharge connec tion

of the separator.

10.

Using the crane, set the new assembly in place and shim

the motor and compressor feet wherer required.

11.

Reattach the drive coupling.

12.

The shaft alignment must be checked and tolerances

verified with the Frick service dept.

13.

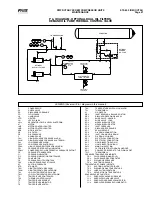

Complete tubing, piping and wiring per the P & I and

wiring diagrams.

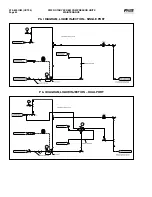

Install the valve and adjust the spring tension accordingly

to maintain the predetermined oil temperature. The rec-

ommended oil temperatures are 130°F for ammonia and

140°F for R-22. Check with Frick service for recommended

oil temperatures for other refrigerants.

If all of the above steps have been properly performed and

the desired oil temperature can not be achieved, contact

Frick Service.