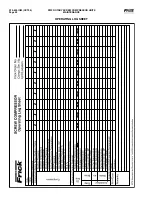

RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 54

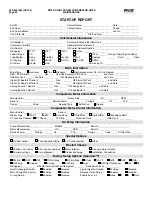

START-UP REPORT

Sold To: _____________________________________ Contact Name: _______________________ Date: ________________

End User: ___________________________________ Contact Name: _______________________ Phone: ______________

End User Address: _________________________________________________________________ Fax No: ______________

City, State, Zip: ________________________________________________ Start-up Rep. _____________________________

Unit General Information

Unit Model # _______________________________

Customer Package Identification # _____________________________

Compressor Serial # _________________________

Separator National Board # ___________________________________

Unit Serial # ________________________________

Oil Cooler National Board # ___________________________________

Refrigerant

R-717

R-22

R-290

Other ____________________

Lube Oil Type

2A

3

4

9

Other _______ Design Operating Conditions

Lube System

None

Prelube

Cycling

Full

Demand

______ °Suct./ _____ °Disch.

Oil Cooling

TSOC

WCOC

S-LIOC

D-LIOC

GCOC

Oil Filters

Single

Dual

Micro Log I.D. _____________________

Micro Information

Micro Type

Quantum

Plus

Standard

Electromechanical U3, U4, U5 Program ____________

SBC / CPU Serial # __________ Rev. ___ U24/U35 Program ID/OS Ver # ____________ and Date _____________

U36 Bios Ver # _______ and Date ___________ U42 Keyboard Ver # _________________ and Date _____________

Digital I/O Board #1 Serial # _____________ Rev. _______ U8 Digital I/O Ver # ____________ and Date _________

Digital I/O Board #2 Serial # _____________ Rev. _______ U8 Digital I/O Ver # ____________ and Date _________

Analog Board #1 Serial # ______________Rev. _____ U13 Analog Ver # _________ and Date ______________

Analog Board #2 Serial # ______________Rev. _____ U13 Analog Ver # _________ and Date ______________

Compressor Motor Information

Manufacturer __________________________________ Frame Size ______________ H.P._____________ RPM __________

Serial # ___________________________Service Factor ______________ Voltage __________ Hz _______ FLA _________

Design ____________Code ______________ Bearing Type

Antifriction

Sleeve

Compressor Motor Starter Information

Manufacturer ___________________________ Serial # ____________________________

Starter Type

WDCT

ATL

Auto-Trans

Solid State

Digital DBS

Standalone DBS

CT Location Checked

CT Phase ______ CT Ratio ________ Transition Time ___________ DBS Ver. # ____________

Oil Pump Information

Pump Manufacturer __________________ Model # ____________________ Serial # _________________________

Motor Manufacturer __________________ H.P. __________ RPM ________ Serial # _________________________

Service Factor ______ Voltage ________ Hz __________ FLA ________ Design ______ Code _____ Starter Size ________

Special Options

DX Economizer

Frick Supplied Starter

PC Control System

Other

Prestart Checks

Position of all valves

All wiring connections

Motor rotation

Oil pump motor rotation

All micro settings

Cold alignment

Proper oil charge

Installation, Foundation

Factory Setup Options (Quantum™)

RWB II

RWF

RXF

RDB 3-Step

RDB 4-Step

Other

GSV II

GST

GSF

GSB

No Pump

Prelube

Cycling

Full Time

Dual

Oil Filter Transducer

Yes

No

Refrigerant ___________ K-Factor for User Defined Refrigerant ________ Slide Valve Travel _____________

Dual Dischaarge Control

Enabled

Disabled

Liquid Injection Cooling

Enabled

Disabled

Main Oil Injection Control

Enabled

Disabled

Balance Piston Setup

Enabled

Disabled

Oil Log Setup

Enabled

Disabled

Enable Aux 1 & 2

None

1

2

Both