RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 11

the.chamber.provided.on.the.oil.outlet.connection..Determine.

the.size.of.the.water-cooled.oil.cooler.supplied.with.the.unit,.

then.refer.to.table.for.the.water.connec.tion.size.and.water.

flow.range.(GPM)..

The water supply must be sufficient to

meet the required flow.

It.is.imperative.that.the.condition.of.cooling.water.and.closed.

loop. fluids. be. analyzed. and. maintained. regularly. and. as.

necessary.to.prevent.corrosion.of.heat.exchanger.surfaces...

The.oxygen.content.of.river.water.and.some.other.cooling.

water.sources.will.oxidize.steel.tubes.and.cause.premature.

failure..Careful.attention.to.water.treatment.is.essential.to.

ensure.adequate.life.of.steel.cooler.tubes.if.cooling.tower.

water.is.used..The.condition.of.heat.exchanger.tubes.should.

be.checked.semiannually.to.prevent.hazard.

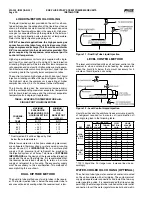

OIL COOLER DATA TABLE

SIZE - Inches

APPROX

WATER FLOW

RANGE (GPM)

...

COOLER

WATER CONN

5.Foot.Lengths

6".DIA.

1..NPT

10.–.23

8".DIA.

1-1/4..NPT

35.–.60

NOTE: The water regulating valve shipped with the unit

will be sized to the specific flow for the unit.

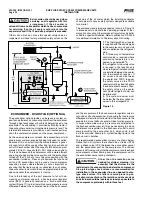

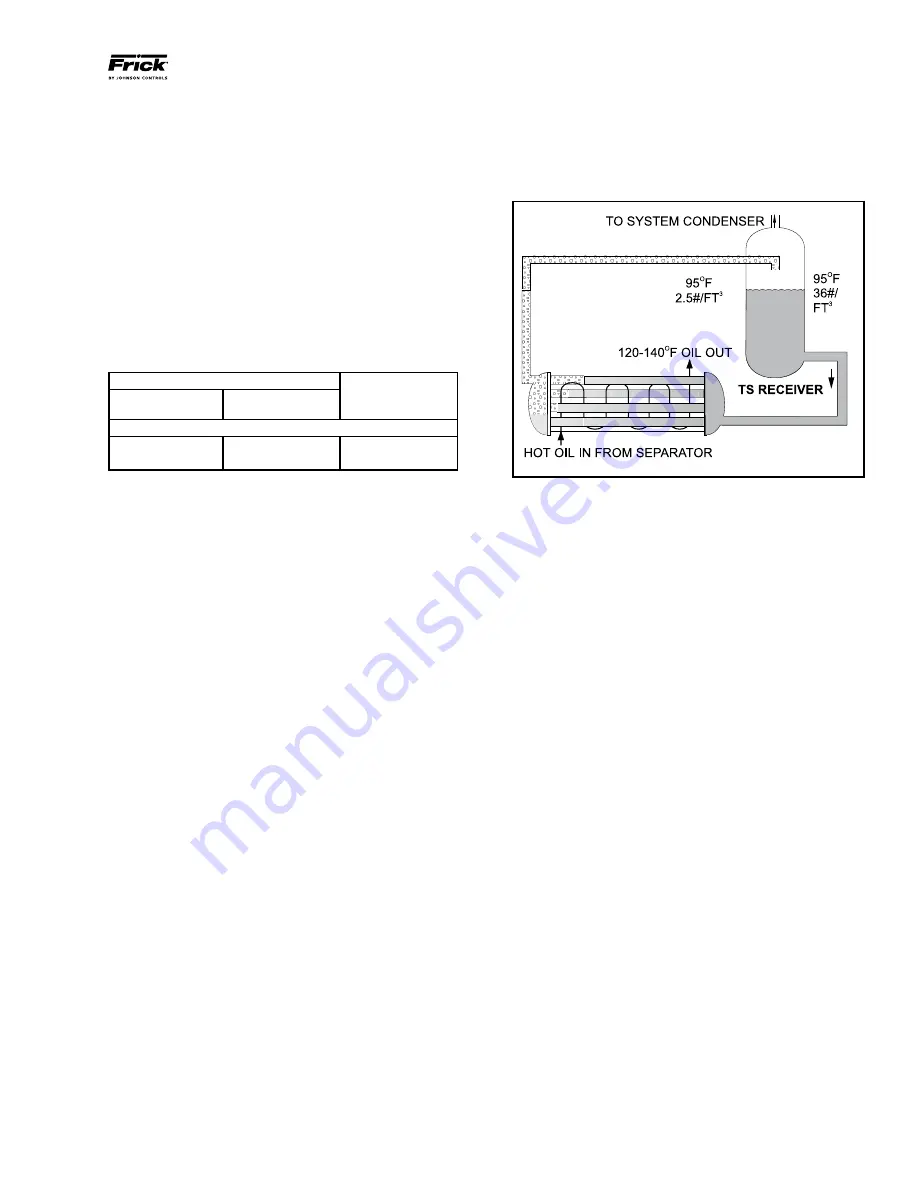

THERMOSYPHON OIL COOLING (OPTIONAL)

Thermosyphon.oil.cooling.is.an.economical,.effective.method.

for. cooling. oil. on. screw. compressor. units..Ther.mosyphon.

cooling.utilizes.liquid.refrigerant.at.condenser.pressure.and.

temperature.which.is.partially.vaporized.at.the.condenser.

temperature.in.a.shell.and.tube-.or.plate-type.vessel.cool-

ing.the.oil.to.within.15°F.of.that.temperature..The.vapor,.at.

condensing.pressure,.is.vented.to.the.condenser.inlet.and.

reliquified..This.method.is.the.most.cost.effective.of.all.cur-

rently.applied.cooling.systems.since.no.compres.sor.capacity.

is.lost.or.compressor.power.penalties.in.curred..The.vapor.

from.the.cooler.need.only.be.con.densed,.not.compressed..

Refrigerant.flow.to.the..cooler.is.automatic,.driven.by.the.

thermosyphon.principle,.and.cooling.flow.increases.as.the.

oil.inlet.temperature.rises.

EQUIPMENT

. -.The. basic. equipment. required. for. a. ther-

mosyphon.system.consists.of:

1.

.A.source.of.liquid.refrigerant.at.condensing.pressure.and.

temperature.located.in.close.proximity.to.the.unit.to.mini.mize.

piping.pressure.drop..The.liquid.level.in.the.refrigerant.source.

must.be.6.to.8.feet.above.the.center.of.the.oil.cooler.

2.

.A.shell.and.tube-.or.plate-type.oil.cooler.with.a.300.psi.

minimum.design.working.pressure.on.both.the.oil.and.re-

frigerant.sides.

Due.to.the.many.variations.in.refrigeration.system.design.

and.physical.layout,.several.systems.for.ensuring.the.above.

criteria.are.possible.

SYSTEM OPERATION

.-.Liquid.refrigerant.fills.the.cooler.tube.

side.up.to.the.Thermosyphon.receiver.liquid.level.

Water.or.hot.oil.(above.the.liquid.temperature).flowing.through.

the. cooler. will. cause. some. of. the. refrigerant. to. boil. and.

vaporize.in.the.tubes..The.vapor.rises.in.the.return.line..The.

density.of.the.refrigerant.liquid/vapor.mixture.in.the.return.

line.is.considerably.less.than.the.density.of.the.liquid.in.the.

supply.line..This.imbalance.provides.a.differential.pressure.

that.sustains.a.flow.condi.tion.to.the.oil.cooler..This.relation-

ship.involves:

1.

.Liquid.height.above.the.cooler.

.

2.

.Oil.heat.of.rejection.

.

3.

.Cooler.size.and.piping.pressure.drops.

Figure 13 - Thermosyphon System Operation

Current.thermosyphon.systems.are.using.two-pass.oil.cool-

ers.and.flow.rates.based.on.4:1.overfeed.

The.liquid/vapor.returned.from.the.cooler.is.separated.in.the.

receiver..The.vapor.is.vented.to.the.condenser.inlet.and.need.

only.be.reliquified.since.it.is.still.at.condenser.pressure.

INSTALLATION

.-.The.shell.and.tube-.or.plate-type.thermo-

syphon.oil.cooler.with.oil-side.piping.and.a.thermostatically.

controlled.mixing.valve.(if.ordered).are.factory.mount.ed.and.

piped..The.customer.must.supply.and.install.all.piping.and.

equip.ment.located.outside.of.the.shaded.area.on.the.piping.

diagram.with.consideration.given.to.the.following:

1.

.The.refrigerant.source,.thermosyphon.or.system.receiv.er,.

should.be.in.close.proximity.to.the.unit.to.minimize.piping.

pressure.drop.

2.

.The.liquid.level.in.the.refrigerant.source.must.be.

6

.to.

8

.

feet

.above.the.center.of.the.oil.cooler.

3.

.A.safety.valve.should.be.installed.if.refrigerant.isolation.

valves.are.used.for.the.oil.cooler.

4.

An.angle.valve.should.be.installed.in.the.piping.before.

the.thermosyphon.oil.cooler.to.balance.the.thermosyphon.

system..Also.recommended.is.the.installation.of.sight.glasses.

at.the.TSOC.inlet.and.outlet.to.aid.in.troubleshooting..The.

factory-mounted,.plate-type.thermosyphon.oil.cooler.requires.

a.refrigerant-side.drain.valve.to.be.provided.and.installed.by.

the.customer.

TSOC AND WCOC OPTIONAL OIL SIDE SAFETY RE-

LIEF -

Compressor.units,.which.have.valves.in.the.oil.piping.

to.isolate.the.oil.cooler.from.the.oil.separator.for.servicing,.

may.have.factory.installed.piping.to.relieve.the.shell.side.(oil.

side).safety.valve.directly.into.the.oil.separator,.as.shown.in.

the.P.&.I.diagrams.on.pages.58.through.60.

This.arrangement.uses.a.special.UV.stamped.safety.valve.

rated.for.liquid.and.vapor.relief..The.safety.valve.is.designed.

for.500.psi.DWP.and.is.set.to.relieve.at.75.psi.delta.P..The.

safety.valve.piping.contains.flanged.connections.should.the.

valve.require.maintenance.or.replacement.