RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 14

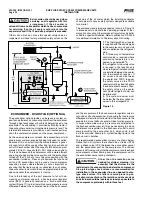

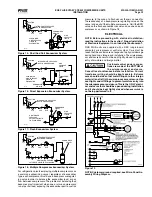

MOTOR STARTER PACKAGE

Motor.starter.and.interlock.wiring.requirements.are.shown.in.

the.wiring.diagram,.above..All.the.equipment.shown.is.sup-

plied.by.the.installer.unless.a.starter.package.is.pur.chased.

from.Frick...Starter.packages.should.consist.of:

NOTE: When compressor mo tor vol tage is dif fer ent from

oil pump mo tor vol tage, supply a circuit breaker discon-

nect for separate feed in lieu of fuses.

1.

.The. compressor. motor. starter. of. the. specified. HP. and.

voltage. for. the. starting. method. specified. (across-the-line,.

autotransformer,.wye-delta,.or.solid.state).

NOTE: If starting methods other than across-the-line are

desired, a motor/compressor torque analysis must be

done to ensure that sufficient starting torque is avail-

able, particularly in booster applica tions. Contact FRICK

Company if assistance is required.

2.

. If. specified,. the. starter. package. can. be. supplied. as. a.

combination.starter.with.circuit.breaker.disconnect..Howev-

er,. the. motor. overcurrent. protection/disconnection. device.

can.be.supplied.by.others,.usually.as.a.part.of.an.electrical.

power.distribution.board.

3.

. A. 2.0. KVA. control. power. transformer. (CPT),. to. supply.

120.volt.control.power.to.the.control.system.and.separator.

oil.heaters,.is.included..If.environmental.conditions.require.

more.than.a.500.watt.oil.heater,.an.appro.priately.oversized.

control.trans.former.will.be.required.

4.

.One.normally.open,.compressor-motor-starter.auxiliary.

contact.and.one.normally.open,.oil-pump-motor-starter.aux-

iliary.con.tact.(opt.).should.be.supplied.and.wired.as.shown.

on.the.starter.package.wiring.diagram..In.addition,.the.com-

pressor.and.oil.pump.motor.starter.(opt.).coils.and.the.CPT.

secondaries.should.be.wired.as.shown.on.starter.package.

wiring.diagram.

5.

.The.compressor.motor.Current.Transformer.(CT).can.be.

installed.on.any.one.phase.of.the.compressor.leads..

NOTE:

The CT must see all the current on any one phase; there-

fore in wye-delta applications, BOTH leads of any one

phase must pass through the CT.

6.

.Oil.Pump.Option:..If.the.optional.oil.pump.is.specified,.

an.oil.pump.starter.must.be.a.com.ponent.of.the.unit.starter.

package..The.pump.starter.should.be.equipped.with.fuses.

or,.in.the.case.where.the.compressor.motor.is.a.different.

voltage.from.the.oil.pump.motor,.a.circuit.breaker.disconnect.

suitable.for.separate.power.feed.

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

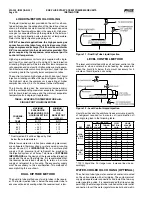

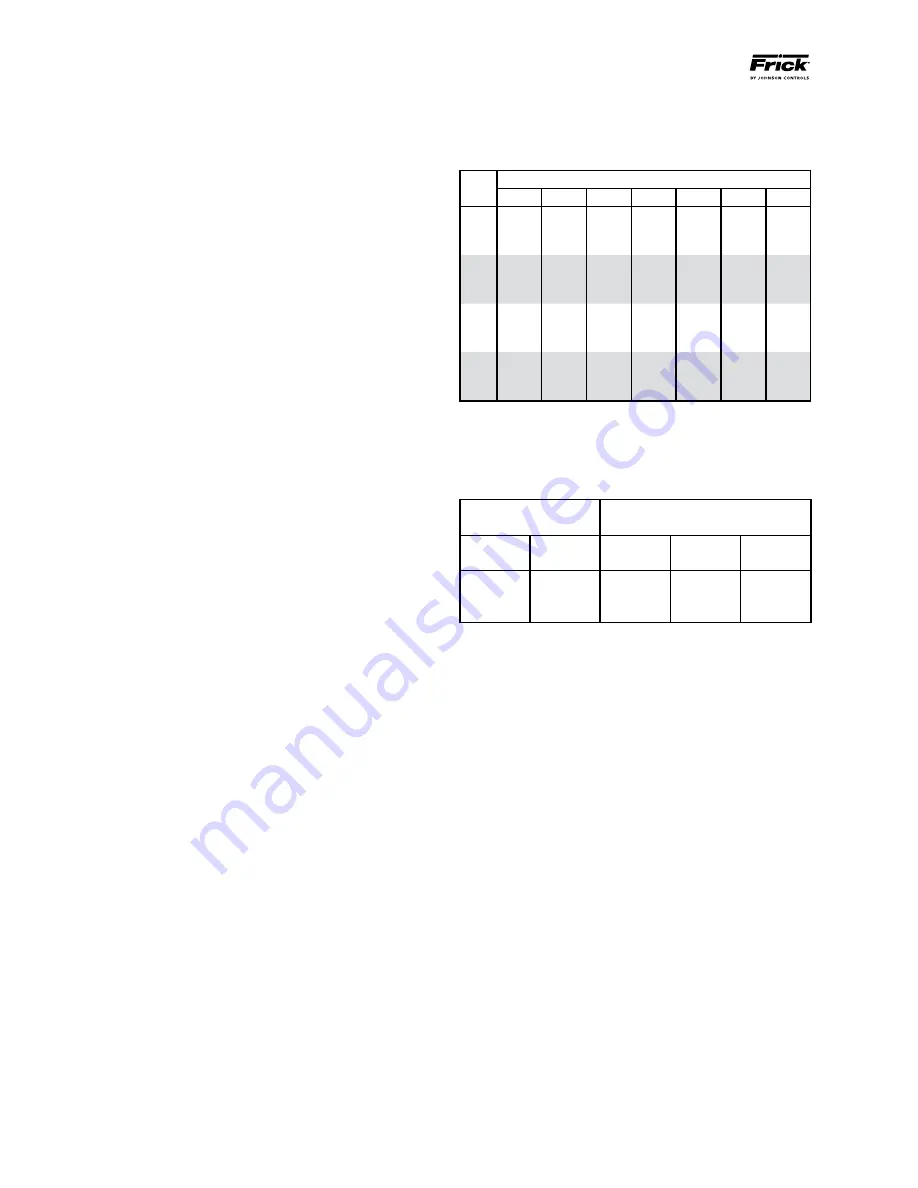

CURRENT TRANSFORMER (CT) RATIOS

The.CT.ratio.for.various.motor.sizes.(with.a.5.amp..second-

ary).is.given.in.the.following.table:

VOLTAGE

HP

200

230

380

460

575

2300 4160

20

100:5

100:5

100:5

100:5

100:5

-

-...

25

100:5

100:5

100:5

100:5

100:5

-

-...

30

200:5

100:5

100:5

100:5

100:5

-

-...

40

200:5

200:5

100:5

100:5

100:5

-

-...

50

200:5

200:5

100:5

100:5

100:5

-

-...

60

300:5

200:5

200:5

100:5

100:5

-

-...

75

300:5

300:5

200:5

200:5

100:5

-

-...

100

400:5

300:5

200:5

200:5

200:5

-

-...

125

500:5

400:5

300:5

200:5

200:5

-

-...

150

500:5

500:5

300:5

300:5

200:5

-

-...

200

800:5

600:5

400:5

300:5

300:5

100:5

50:5.

250

800:5

800:5

500:5

400:5

300:5

100:5

50:5

MINI MUM BURDEN RATINGS

The.following.table.gives.the.minimum.CT.burden.ratings..

This.is.a.function.of.the.distance.between.the.motor.starting.

package.and.the.compressor.unit.

BURDEN

RATING

MAXIMUM DISTANCE FROM

FRICK PANEL

ANSI

VA

USING #

14 AWG

USING #

12 AWG

USING #

10 AWG

B-0.1

2.5

15.ft

25.ft

40.ft

B-0.2

5

35.ft

55.ft

88.ft

B-0.5

12.5

93.ft

148.ft

236.ft

In.addition.to.the.starter.package.interlocks.shown.on.the.

starter. package. diagram,. the. following. optional. interlocks.

are.on.the.typical.RXB.PLUS.Screw.Compressor.unit.with.

the.SBC.Microprocessor.Control.System.wiring.diagram:

1.

.Remote.LOAD,.UNLOAD,.and.RUN.interlocks.in.case.the.

customer.desires.to.operate.the.unit.from.a.remote.control.

device.

2.

.Alarm.Horn.output.

3.

.Control.solenoid.valve.for.the.economizer.option.

For.customer.control.options,.consult.FRICK.

NOTE: The microprocessor will not operate without

EPROM chips installed. When EPROM chips are not

installed, the microprocessor display will typically in-

dicate two dark lines across both the upper and lower

display screens.

BATTERY BACKUP

The.battery.backup.prevents.data.loss.during.power.interrup-

tion..It.will.maintain.the.adjustable.setpoints.stored.in.RAM.

(Random.Access.Memory).for.up.to.1.year.after.power.loss..

Expected.battery.life.is.10.years..A.trickle.charge.maintains.the.

battery.backup.at.peak.charge.when.control.voltage.is.present.

To.prevent.power.loss,.the.battery.backup.is.shipped.disabled..

To.enable.the.battery.backup,.a.jumper.pin.located.near.the.

top.of.the.microprocessor.circuit.board.(see.illustration.page.

52).must.be.moved.from.OFF.(pins.1-2).to.ON.(pins.2-3).

NOTE: It is not necessary to disconnect the battery

backup during extended downtime.