RXB PLUS ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.101-IOM (JAN 13)

Page 30

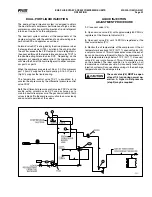

RXB COMPRESSOR

The. Frick.

RXB

. rotary. screw. compressor. utilizes. mating,.

asymmetrical-profile.helical.rotors.to.provide.a.continuous.

pulse-free.flow.of.refriger.ant.vapor.and.is.designed.for.both.

high.pressure.and.low.pressure.applications..The.compres.sor.

incorporates.the.following.features:

1.

.High-capacity.roller.bearings.to.carry.radial.loads.at.both.

the.inlet.and.outlet.ends.of.the.compressor.

2.

. Heavy-duty,. four-point,. angular-contact. ball. bearings.

to. carry. axial. loads. are. mounted. at. the. discharge. end. of.

compressor.

3.

. Moveable. slide. valve. to. provide. infinite. step. capacity.

control.from.100.to.25%.of.full.load.

4.

.VOLUMIZER

®

.adjusts.to.the.most.efficient.of.three.volume.

ratios. (2.2,. 3.5. or. 5.0). depending. upon. system. require-

ments.

5.

. A. hydraulic. unloader. cylinder. to. operate. the. slide. stop.

and.slide.valve.

6.

. Compressor. housing. suitable. for. 350. PSI. pressure..

Dual-.compressor.casing.design.for.very.low.airborne.noise.

trans.mission.

7.

.Most.bearing.and.control.oil.vented.to.closed.thread.in.

the.compressor.instead.of.suction.port.to.avoid.performance.

penalties.from.superheating.suction.gas.

8.

.Shaft.seal.design.to.maintain.operating.pressure.on.seal.

well.below.discharge.pressure.for.increased.seal.life.

9.

.Oil.injected.into.the.rotors.to.maintain.good.volumetric.and.

adiabatic.efficiency.even.at.very.high.compression.ratios.

IT IS MANDATORY THAT THE COU-

PLING CENTER BE REMOVED

AND THE DIRECTION OF MOTOR

ROTATION BE CONFIRMED

BEFORE

RUNNING THE

COMPRESSOR. Proper rotation of the compressor shaft

is clockwise looking at the end of the compressor shaft.

FAILURE TO FOLLOW THIS STEP COULD RESULT IN

BACKWARD COMPRESSOR ROTATION WHICH CAN

CAUSE COMPRESSOR FAILURE OR EXPLOSION OF

THE SUCTION HOUSING.

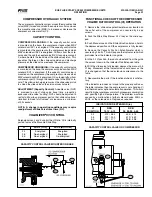

COMPRESSOR LUBRICATION SYSTEM

The.

RXB

.compressor.is.designed.specifically.for.operation.

without. an. oil. pump. for. high. stage. service.. Boosters. and.

some.low-differential-pressure.appli.cations.will.require.the.

full-lube.pump.option.

The.lubrication.system.on.an.

RXB

.screw.compressor.unit.

performs.several.functions:

1.

.Lubricates.the.rotor.contact.area,.allowing.the.male.rotor.

to.drive.the.female.rotor.on.a.cushioning.film.of.oil.

2.

.Provides.lubrication.of.the.bear.ings.and.shaft.seal.

3.

.Serves.to.remove.the.heat.of.compression.from.the.gas,.

keeping.discharge.temperatures.low.and.minimizing.refriger-

ant.or.oil.break.down.

4.

.Fills.gas.leakage.paths.between.or.around.the.rotors.with.

oil,.thus.greatly.reducing.gas.leakage.and.main.tain.ing.good.

compressor.per.formance.even.at.high.compres.sion.ratios.

5.

.Provides.oil.pressure.for.development.of.balance.load.on.

the.balance.pistons.to.reduce.bearing.loading.and.increase.

bearing.life.

FULL-LUBE OIL SYSTEM

RXB PLUS

.booster.compressors.and.high-stage.compres-

sors,.that.operate.with.very.low.differential.pressures.across.

the.compressor.suction.and.compres.sor.discharge,.require.

a.full-time.oil.pump.to.produce.the.oil.flow.and.pressures.

required..Oil.is.pumped.from.the.oil.separator.through.the.

oil.filter.to.the.main.oil.injection.feed.and.the.compressor...

An.oil.pressure.regulating.valve.downstream.of.the.pump.is.

used.to.regulate.oil.pressure.at.the.compressor.by.returning.

excess.oil.to.the.separator.

Oil.pressure.on.

RXB PLUS

.compressors.with.full-time.oil.

pumps. should. be. adjusted. to. provide. 20. –. 25. PSI. (high.

stage).or.30.–.35.PSI.(booster).pounds.of.oil.pressure.at.

the.highest.normal.head.pressure.or.intermediate.pressure.

expected.with.the.compressor.fully.loaded..The.compressor.

will.require.maximum.oil.flow.under.these.conditions.

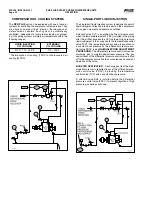

COMPRESSOR OIL SEPARATION SYSTEM

The.

RXB PLUS

.is.an.oil.flooded.screw.compressor...Most.

of.the.oil.discharged.by.the.compressor.separates.from.the.

gas.flow.in.the.oil.charge.reservoir..Some.oil,.however,.is.

discharged.as.a.mist,.which.does.not.separate.readily.from.

the. gas. flow. and. is. carried. past. the. oil-charge. reser.voir..

One.or.more.coalescer.filter.elements.then.coalesce.the.oil.

mist.into.droplets;.the.droplets.of.oil.fall.to.the.bottom.of.the.

coalescer.section.of.the.oil.separator..The.return.of.this.oil.

to.the.compressor.is.controlled.by.a.needle.valve.on.both.

high-stage.and.booster.applications.

NOTE: Open needle the valve only enough to keep the

coalescer end of the separator free of oil.

The. sight. glass. located. near. the. bottom. of. the. coales.cer.

section. of. the. oil. separator. should. remain. empty. during.

normal.operation..If.an.oil.level.develops.and.remains.in.the.

sight.glass,.a.problem.in.the.oil.return.separation.system.or.

compressor.operation.has.develop.ed..Refer.to.Maintenance.

for.information.on.how.to.correct.the.problem.

NOTE: Normal operating level is between the top sight

glass and bottom sight glass.