RXB PLUS ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.101-IOM (JAN 13)

Page 63

Do.not.drill.into.an.electronic.control.panel.to.locate.conduit.

connections..You.are.probably.not.entering.the.panel.where.

the.manufacturer.would.like.you.to.since.most.manufactur-

ers.recommend.or.provide.prepunched.conduit.connections...

You.may.also.be.negating.the.NEMA.rating.of.the.enclosure..

Drilling.can.cause.metal.filings.to.land.on.the.electronics.and.

create.a.short.circuit.when.powered.is.applied..If.you.must.

drill.the.panel,.take.the.following.precautions:.

•

. First,.call.the.panel.manufacturer.before.drilling.into.the.

panel.to.be.sure.you.are.entering.the.panel.at.the.right.

place..

•

. Take.measures.to.avoid.ESD.(electrostatic.discharge).to.

the. electronics. as. you. prep. the. inside. of. the. Electronic.

control.panel..This.can.be.done.by.employing.an.antistatic.

wrist.band.and.mat.connected.to.ground..

•

. Cover.the.electronics.with.plastic.and.secure.it.with.mask-

ing.or.electrical.tape..

•

. Place.masking.tape.or.duct.tape.on.the.inside.of.the.panel.

where.you.are.going.to.drill..The.tape.will.catch.most.of.

the.filings..

•

. Clean. all. of. the. remaining. filings. from. the. panel. before.

removing.the.protective.plastic..

When. routing. conduit. to. the. top. of. an. electronic. control.

panel,.condensation.must.be.taken.into.consideration..Water.

can.condense.in.the.conduit.and.run.into.the.panel.causing.

catastrophic.failure..Route.the.conduit.to.the.sides.or.bottom.

of.the.panel.and.use.a.conduit.drain..If.the.conduit.must.be.

routed.to.the.top.of.the.panel,.use.a.sealable.conduit.fitting.

which. is. poured. with. a. sealer. after. the. wires. have. been.

pulled,. terminated,. and. the. control. functions. have. been.

checked..A.conduit.entering.the.top.of.the.enclosure.must.

have. a. NEMA-4. hub. type. fitting. between. the. conduit. and.

the.enclosure.so.that.if.water.gets.on.top.of.the.enclosure.it.

cannot.run.in.between.the.conduit.and.the.enclosure..This.

is.extremely.important.in.outdoor.applications.

NOTE: It is simply NEVER a good practice to enter

through the top of an electronic control panel or starter

panel that does not already have knockouts provided. If

knockouts are not provided for this purpose it is obvious

this is not recommended and could VOID WARRANTY.

Never add relays, starters, timers, transformers, etc. in-

side an electronic control panel without first contacting

the manufacturer.

Contact. arcing. and. EMI. emitted. from.

these.devices.can.interfere.with.the.electronics..Relays.and.

timers.are.routinely.added.to.electronic.control.panels.by.the.

manufacturer,.but.the.manufacturer.knows.the.acceptable.

device. types. and. proper. placement. in. the. panel. that. will.

keep.interference.to.a.minimum..If.you.need.to.add.these.

devices,.contact.the.manufacturer.for.the.proper.device.types.

and.placement....

Never run refrigerant tubing inside an electronic control

panel.

If.the.refrigerant.is.ammonia,.a.leak.will.totally.destroy.

the.electronics.

If the electronic control panel has a starter built into the

same panel, be sure to run the higher voltage wires where

indicated by the manufacturer.

. EMI. from. the. wires. can.

interfere.with.the.electronics.if.run.too.close.to.the.circuitry.

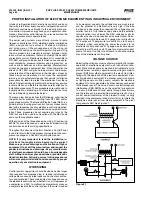

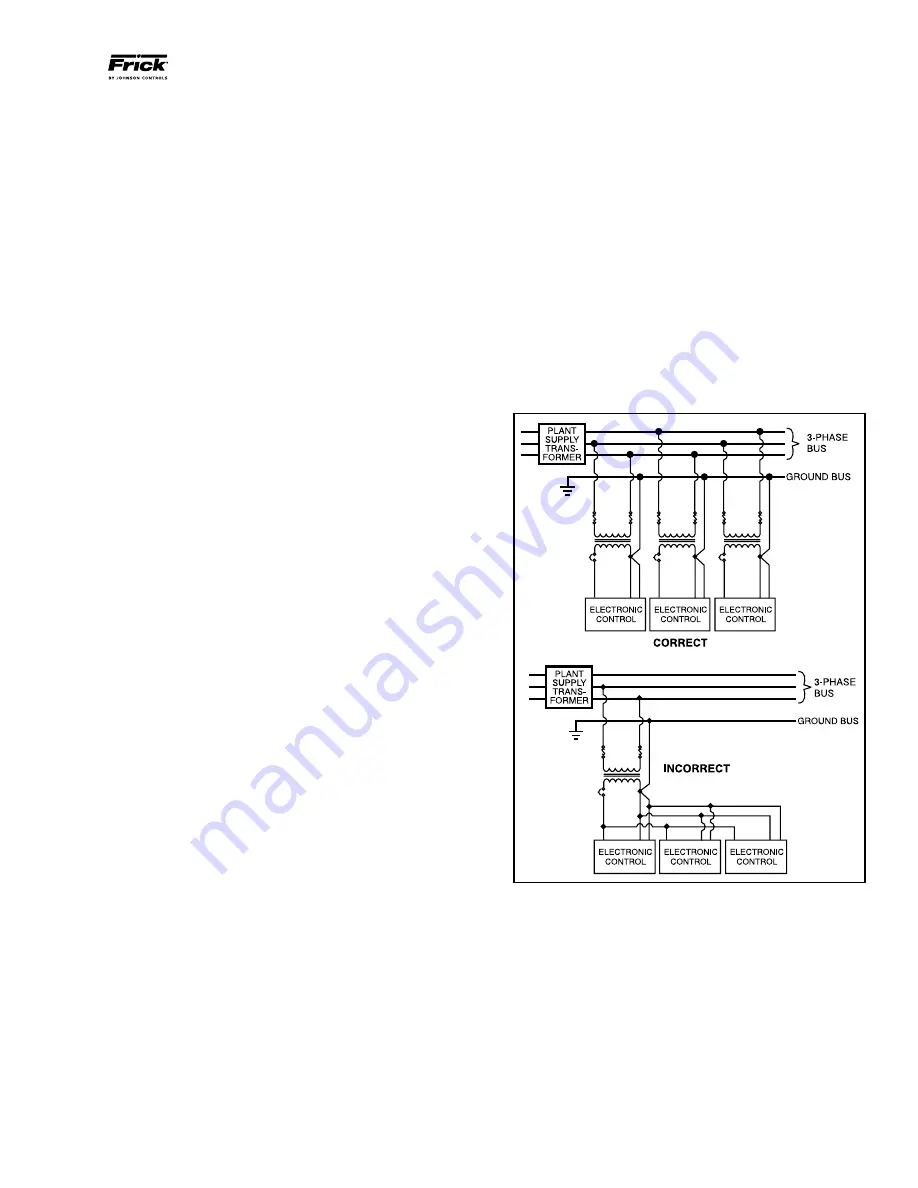

Never daisy-chain or parallel-connect power or ground

wires to electronic control panels.

.Each.electronic.control.

panel.must.have.its.own.control.power.supply.and.ground.

wires.back.to.the.power.source.(Plant.Transformer)..Multiple.

electronic.control.panels.on.the.same.power.wires.create.

current.surges.in.the.supply.wires,.which.may.cause.control-

ler.malfunctions..Daisy-chaining.ground.wires,.taking.them.

to. ground. at. each. device,. allows. ground. loop. currents. to.

flow.between.electronic.control.panels.which.also.causes.

malfunctions..See.Figure.25.

Figure 25