Operating manual- SAB 355 (including ATEX)

004059 en 2019.11

35/63

discharge pressure. During normal compressor operation, the compressor unit essentially oper-

ates as its own oil pump. All oil entering the compressor is moved by the compressor rotors out

the compressor outlet and back to the oil separator.

For normal high-stage operation an oil pump is not required.

6.8

Demand pump oil system

This system is designed to provide adequate compressor lubrication when the oil differential pres-

sure across the compressor suction and discharge side is low. It applies to high-stage and booster

applications.

On start-up, the control system calculates the differential pressure between the compressor dis-

charge and the main oil injection port. If this differential pressure is less than 2.5 bar [35 psi], the

demand pump will turn on and continue to run until obtaining a 3 bar [45 psi] differential

pressure.

Note:

For alarm descriptions and shutdown or cut-out parameters, see separate control system

manual.

6.9

Compressor oil separation system

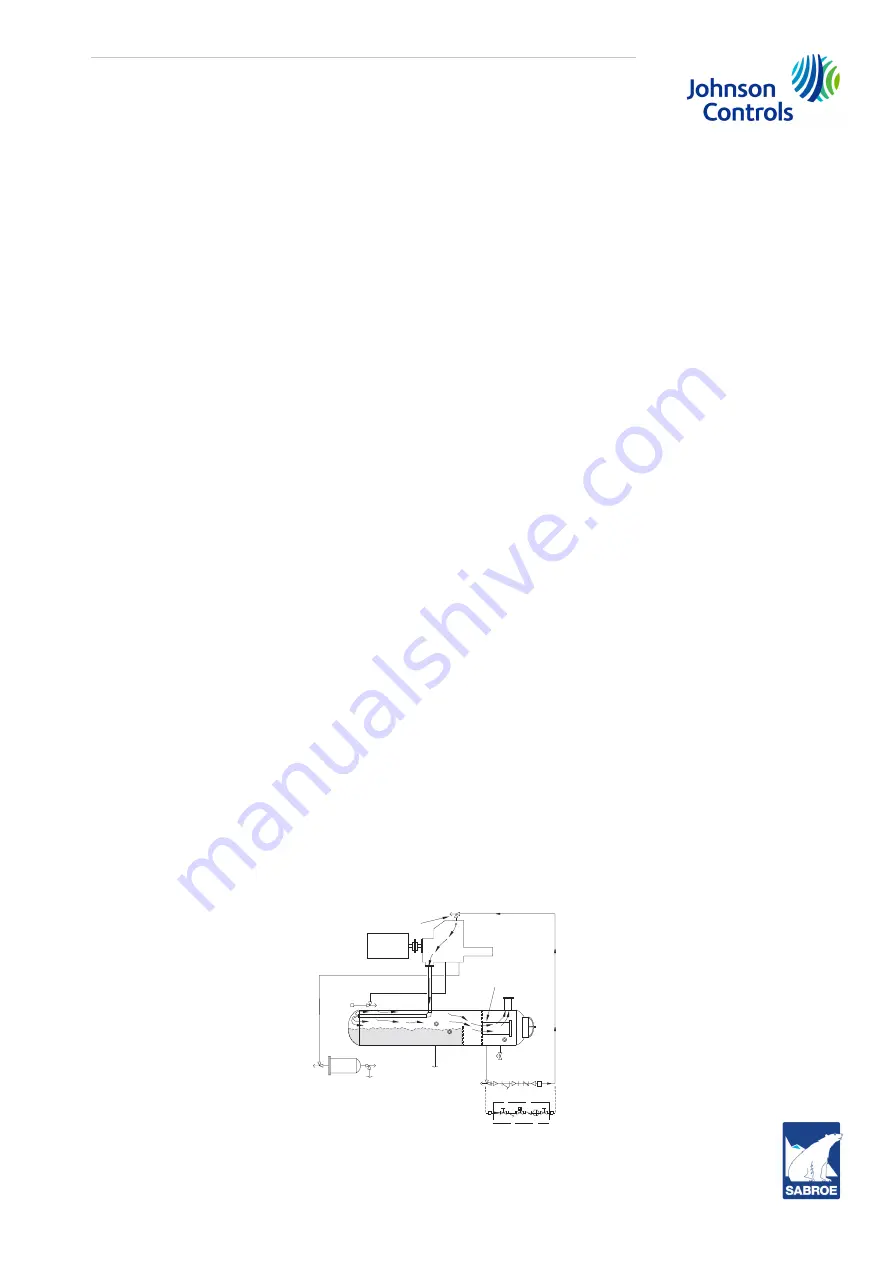

The compressor is an oil flooded screw compressor. Most of the oil discharged by the compressor

separates from the gas flow in the oil charge reservoir. Some oil, however, is discharged as a mist

which does not separate readily from the gas flow and is carried past the oil charge reservoir. One

or more coalescer elements then coalesce the oil mist into droplets which fall to the bottom of the

coalescer section of the oil separator. See Fig. 16. The return of this oil to the compressor is con-

trolled by a throttling valve on both high stage and booster applications.

Note:

Original: Open needle valves only enough to keep coalescer end of separator free from oil.

The sight glass located near the bottom of the coalescer section of the oil separator should remain

empty during normal operation. If the oil level rises and remains in the sight glass, there is a

problem in the oil return separation system or compressor operation. Refer to chapter

for information on how to correct the problem.

Note:

Automatic: Open service valves completely to keep coalescer end of separator free of oil.

The sight glass in the valve indicates flow variations.

Note:

Normal operating oil level is halfway in the top sight glass, which is located midway along

the oil separator shell.

Fig. 16: Principle oil separation system

Compressor

Note: Original only!

Throttling valve

Motor

Oil charge

To oil cooler

Coalescer

element

From oil pump/oil cooler

OF-1

Separator

Automatic oil return

NC