Operating manual- SAB 355 (including ATEX)

004059 en 2019.11

43/63

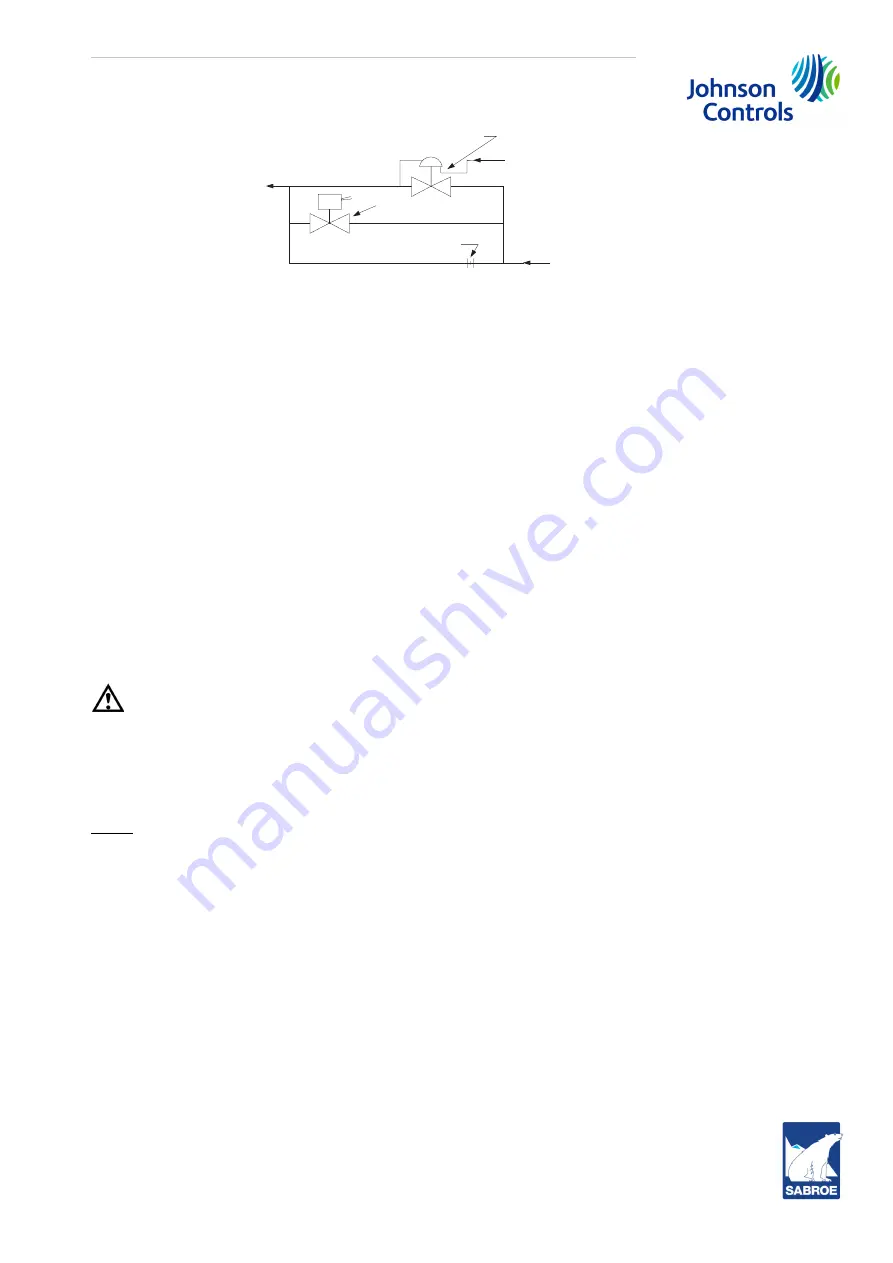

Fig. 23: High-stage SB-2 oil supply line diagram (SAB 355 H only)

6.19

Low ambient temperature operation

It is recommended that oil separators are insulated as a minimum requirement to preserve the

heat generated by the oil heaters. It is important that the coalescer end of the separator is insu-

lated to prevent refrigerant condensation.

On systems located outdoors, or in unheated buildings, where the ambient temperature may drop

below 0° C, insulation and heat tracing of the compressor lubricating oil systems, including oil

lines, oil filters, oil pumps and oil coolers, is mandatory. Freeze-up protection must also be pro-

vided for all water-cooled equipment.

SABROE heat pumps always have insulation and heat tracing.

6.20

Heating element

To keep the compressor lubricating oil warm during a period of standstill, a heating element is

built into the oil reservoir. Before start-up, the heating element must be switched on for 6-8 hours

to ensure that only a minimum of refrigerant remains in the oil. If there is too much refrigerant in

the oil, the oil loses its lubricating properties.

Warning!

The heating element must not be switched on if the oil level in the reservoir is below minimum in

the sight glass. Normally, it must be turned off when the compressor is in operation.

Remember to turn off the heating element before draining the oil through the compressor service

valve and before opening into the oil reservoir for inspection.

ATEX:

On ATEX-executions, the heating element(s) are ATEX-approved. Heating elements from Johnson

Controls Denmark have a thermostat with manual reset. If the thermostat drops out, only compe-

tent personnel should reactivate it.

6.21

Start-up

Preparations before start-up

1.

Turn on the power voltage and the control voltage. Check the emergency stop button.

2.

Check the oil level in the oil separator, see subsection

8.4 Oil .

3.

Check that all valves are positioned in accordance with

Table 6: Valve positions during op-

including the secondary side of the oil cooler.

4.

Reset all alarms according to the control system instructions.

5.

Check on the control display that the compressor capacity control system is in minimum

slide pos. 0-4%.

Pressure-regulating valve(A4ALE)

From compressor

discharge or oil

manifold

Solenoid valve

Restriction orifice (pipe)

From oil manifold

To SB-2

compressor

port