Engineering

manual

-

SAB

193-233-283

S

A-frame

(including

ATEX)

122/168

008831

en

2020.10

_2020.11

13. Install the unitised flex disc in the other end of the coupling. The unitised flex disc, as in-

stalled, should look flat and parallel with the mating hub and spacer flanges.

14. Torque the disc pack lock nuts as recommended in Table 47.

Hold the bolts in place while

the lock nuts are torqued.

Turning the bolts will damage the flex disc.

15. Centre the coupling between the shafts. Make sure that the keys are fully engaged in their

keyways.

The average gap dimension ‘G’ as shown in Fig. 83 at each disc pack should be within the value

given in Table 47 +/-12.5% of the axial capacity of the coupling.

16. To improve the coupling installation and performance, it is recommended, if possible at

this stage, to rotate the assembly a few times while repeatedly rapping the spacer flange

OD with a soft dead blow hammer to relieve any binding in the disc packs.

BPU

series

Disc pack

lock nut

Hub clamping

bolts

Keyway

set

screw

torque

(Nm)

Size NC

Clamp

bolts

‘A’ dia.

(mm)

‘G’

(mm)

Coupling

axial

capacity

(mm)

Torque

(lube)

(Nm)

Size

UNF

Torque

(Nm)

Size

UNF

Size

UNF

BPU-38

30

5

/

16

-24

14.9

1/4-28

30

3

/

8

-16

1

/

4

-28

149

10.2

± 0.71

BPU-41

75

7

/

16

-20

31.2

5/16-24

30

3

/

8

-16

5

/

16

-24

162

14

± 0.74

BPU-47

162.7

9

/

16

-18

55.6

3/8-24

68

1

/

2

-13

3

/

8

-24

183

15.7

± 0.76

BPU-54

162.7

9

/

16

-18

89.5

7/16-20

68

1

/

2

-13

7

/

16

-20

208

15.7

± 1.27

BPU-56

162.7

9

/

16

-18

136.9

1/2–20

68

1

/

2

-13

1

/

2

-20

222

15.7

± 2.03

Table 47: BPU series coupling data

G:

The distance between spacer and coupling hub, both sides. See Fig. 83

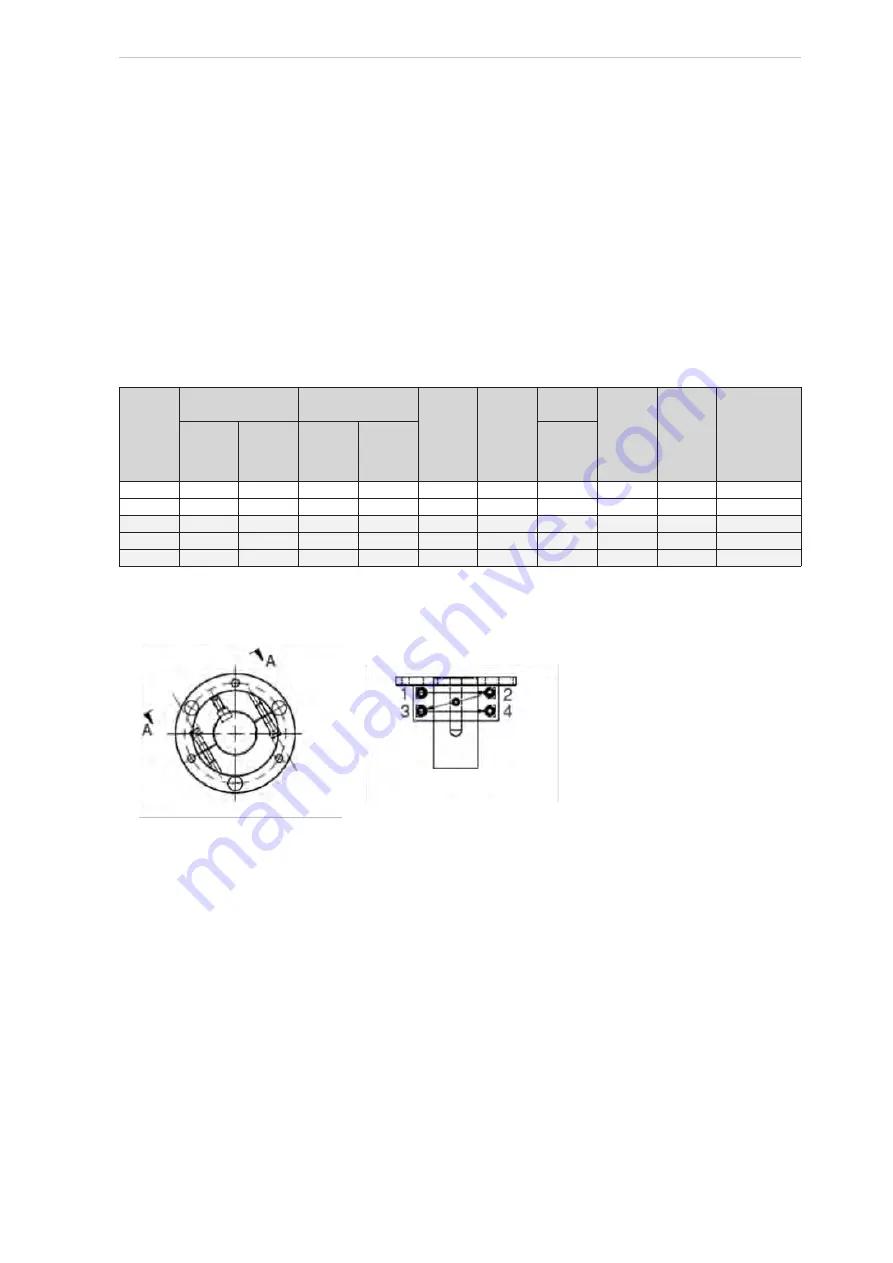

Fig. 84: Clamp hub design

Tighten the clamp screws in three stages. With each stage, follow the tightening sequence pat-

tern shown in section A-A in Fig. 84.

1.

Hand tighten with an Allen wrench.

2.

Tighten to half the clamp screw tightening torque value shown in Table 47 (according to

the coupling size).

3.

Tighten to the full clamp screw tightening torque value shown in Table 47 according to the

coupling size. Continually repeat the tightening sequence of section A-A until all bolts are

completely tightened. Tighten the set screw per the appropriate value shown in Table 47

according to the coupling size.

Section A-A

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......