Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

126/168

008831 en 2020.10

•

test pressure

•

comments

7.31

Evacuation of the refrigeration plant

After pressure testing, the refrigeration plant must be evacuated to remove atmospheric air and

moisture. Evacuation must be carried out on all types of plants, regardless of the refrigerant type

to be charged to the plant.

Note that HCFC and HFC refrigerants mix only minimally with water. Consequently, it is important

to carry out evacuation of such plants with particular care.

The boiling point of a liquid is defined as the temperature where the steam pressure equals at-

mospheric pressure. The boiling point of water is 100° C. If the pressure is reduced, the boiling

point will also be reduced.

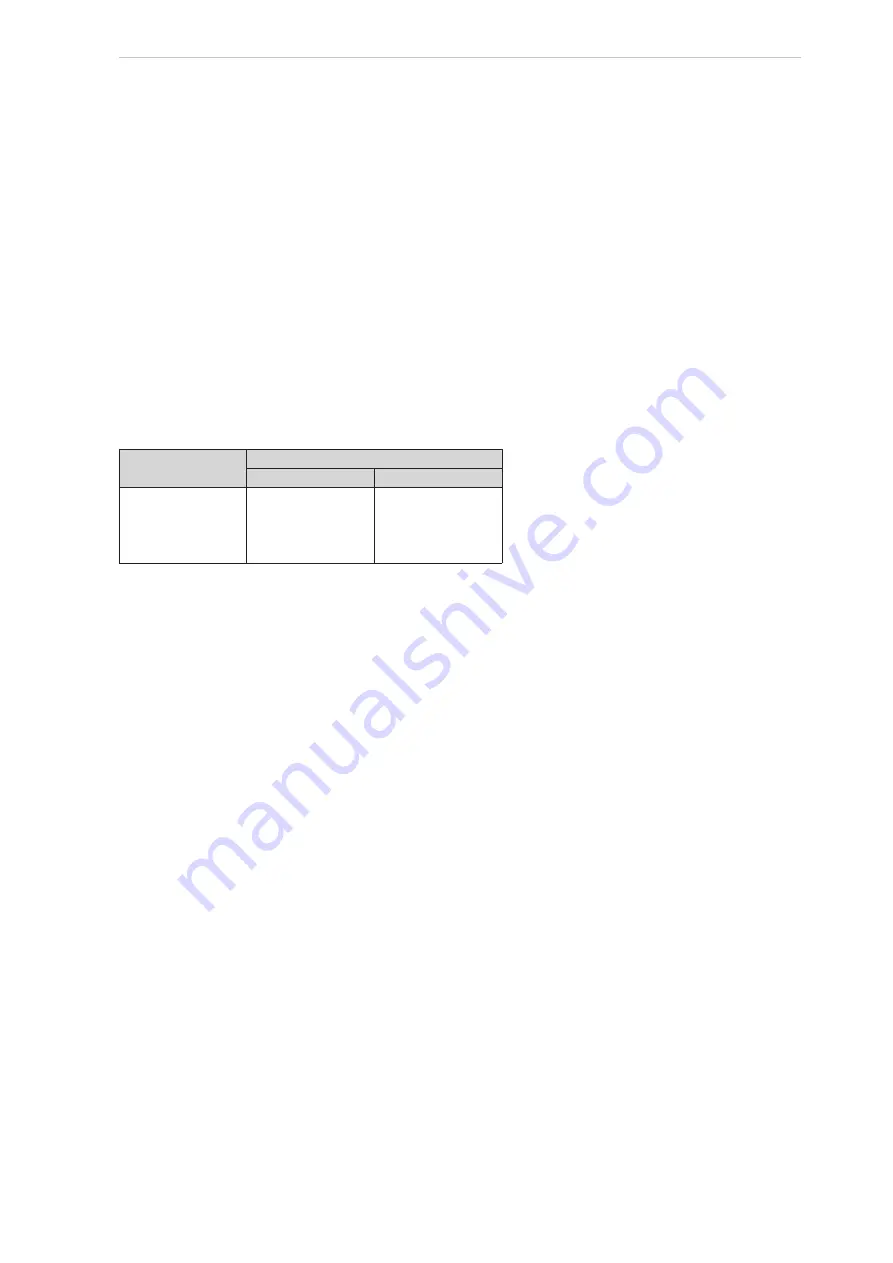

The following table shows the boiling points of water at very low pressure levels.

Boiling point

of water °C

At pressure

mm Hg

bar

5

10

15

20

6.63

9.14

12.73

17.80

0.0088

0.0122

0.0170

0.0237

For evacuation, use a vacuum pump to empty the plant of air and steam. The vacuum pump must

be able to reduce the pressure to approximately 700 Pa (5 mm Hg mercury column) and must be

fitted with a gas ballast valve. This valve should be used wherever possible to prevent water va-

pour condensing in the vacuum pump.

Important!

Never use the refrigeration compressor to evacuate the plant.

To perform an evacuation satisfactorily, the final pressure must be lower than 5 mm Hg. Please

note that water left in the refrigeration plant may freeze if ambient temperatures are lower than

105°C. In such cases it is necessary to supply heat to the component surroundings as ice evapo-

rates with difficulty.

It is recommended to carry out evacuation as follows:

•

Evacuate to a pressure lower than 5 mm Hg.

•

Blow dry air or nitrogen into the system to a pressure corresponding to atmospheric

pressure.

Never use OXYGEN cylinders

•

Repeat evacuation to reduce pressure to less than 5 mm Hg.

•

Shut off the vacuum pump from the refrigeration plant and check that the pressure does

not rise within the next couple of hours. If the system still contains water, this will evapo-

rate and cause the pressure to rise thereby indicating unsatisfactory evacuation. In such

cases, repeat the above procedure.

7.32

Oil charging

The compressor unit is usually delivered without oil and must therefore be charged with oil before

start-up. The oil is chosen according to the

Sabroe oil recommendation

. Oil charging is carried out

by means of a special oil pump. Subsection

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......