Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

134/168

008831 en 2020.10

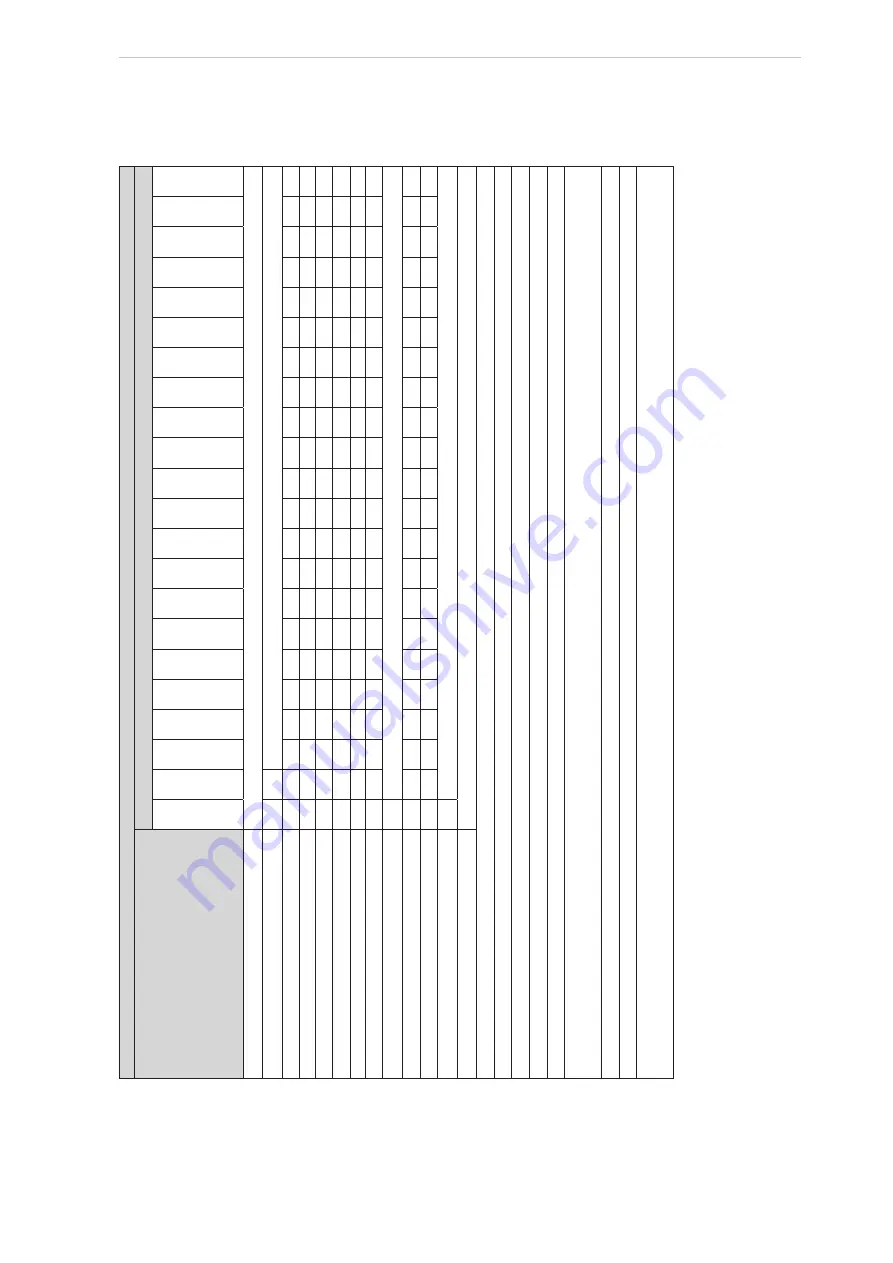

Maintenance

intervals

Maintenance

schedule

Hours

operation

(maximum)

200

1000

5000

8000

10000

15000

20000

25000

30000

35000

40000

45000

50000

55000

60000

65000

70000

75000

80000

85000

90000

95000

Change

oil

As

directed

by

oil

analysis

Oil

analysis

x

Every

6

months

Change

filters

x

x

x

x

x

x

x

x

x

x

x

Clean

oil

strainers

x

x

x

x

x

x

x

x

x

x

x

Clean

liquid

stra

iners

x

x

x

x

x

x

x

x

x

x

x

Change

coalescers

(d)

x

x

x

x

x

x

Check

and

clean

suction

screen

x

x

x

x

x

x

x

x

x

x

x

x

Check

alignment

(e)

x

x

x

x

x

x

x

x

x

x

x

Check

coupling

(a)

x

Annually

regardless

of

operating

hours

Check

electrical

connections

(b)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Check

sensor

calibratio

n

(c)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Vibr

ation

analysis

(f

)

x

Every

6

months,

more

frequently

if

levels

increase

R

eplace

shaft

seal

When

leak

rate

exceeds

7-8

drops

per

minute

(a)

Check

bolts,

shim

packs,

centre

inserts,

keys

and

all

bolt

torque.

(b)

Check

and

torque

all

terminals

in

the

processor

and

starter

panel

per

the

specification

posted

in

the

enclosure.

(c)

Check

calibration

of

slide

valve

,

slide

stop

and

pressure.

(d)

Booster:

20,000

h.

High-stage/air

conditioning:

10,000

h.

One

stage:

30,000

h.

(e)

Not

for

flange

motors.

(f

)

Vibrat

ion

measurement

must

be

carried

out

continuously

to

obtain

optimum

preventive

control

on

bearings.

If

not

continuously

controlled

then

every

6

months,

more

frequently

if

levels

increase.

Alternatively

,

major

overhaul

after

maximum

30000

h.

(g)

V

erify

tightness

of

bolts

on

suction

and

discharge

flanges

on

a

daily

basis.

See

for

torque

requirements.

Leak

test:

According

to

national

rules

or

as

a

minimum

according

to

EN

378-2

(Minimum

annually

if

leak

rate

<

1%

year)

Safety

equipment:

Check

of

safety

equipment

(Safety

switch

devices,

pressure

relief

valve)

according

to

national

rules.

Minimum

requirement

according

to

EN

378,

annual

check

of

safety

switch

devices

and

every

5

years

for

pressure

relief

valve.

Table 49: Maintenance intervals

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......