Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

40/168

008831 en 2020.10

Sabroe Factory have gained comprehensive experience in VSD, and we are integrating this

knowledge into both the mechanical design and the control systems of our products. For this rea-

son, we cannot accept liability for any damage related to vibrations or variable speed drive on

non-factory-built equipment. This includes both mechanical and electrical equipment, meaning

that VSD equipment must be purchased as complete factory-built and tested packages to ensure

optimum reliability and to attain full factory warranty coverage. It should be noted that vibrations

may appear as structural vibrations in for instance frames, piping and instrumentation, or as tor-

sional vibrations in rotating equipment: compressor shaft, coupling and motor rotor.

4.7

Compressor lubrication system

The lubrication system on a screw compressor unit performs several functions:

•

It provides lubrication to bearings and seal.

•

It provides a cushion between the rotors to minimise noise and vibrations.

•

It helps keep the compressor cool and prevents overheating.

•

It provides an oil supply to hydraulically actuate the slide valve and slide stop.

•

It provides oil pressure to the balance pistons to increase bearing life.

•

It provides an oil seal between the rotors to prevent rotor contact or gas bypassing.

The compressor unit may be equipped with either a “no pump” or a “demand pump” lubrication

system. Additionally, either system may contain:

•

Dual oil filters and liquid injection.

•

Water-cooled or thermosyphon oil cooler for compressor oil cooling.

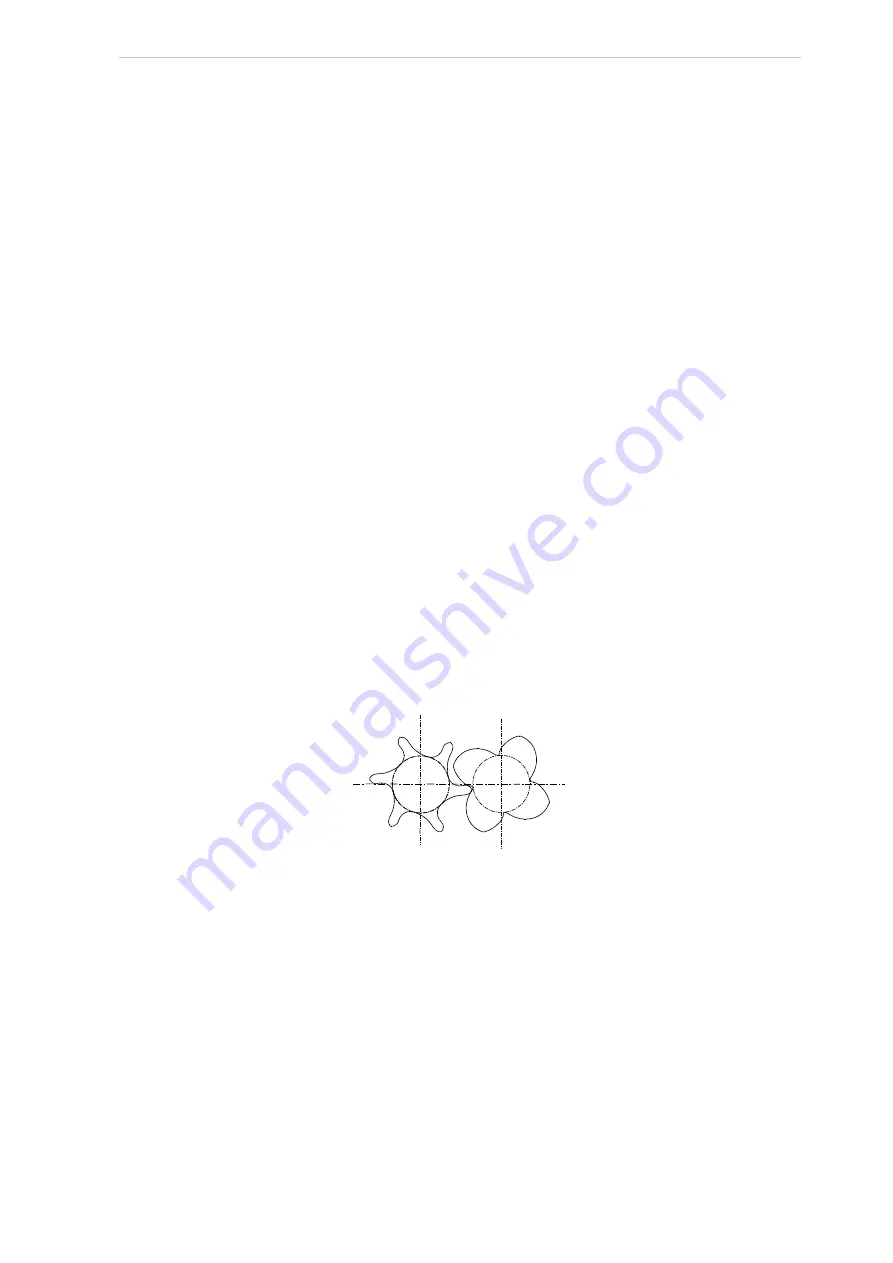

The rotors are constructed with an asymmetrical profile. The male rotor has four lobes, and the

female rotor has six, see Fig. 18.

Fig. 18: Female/male rotor

A shaft seal is mounted at the shaft end (driving shaft) of the male rotor. The shaft seal ensures

complete tightness between the compressor housing and the compressor shaft, thus preventing

atmospheric air from entering the compressor.

4.8

Oil injection valve

In order to control the amount of oil being led to the rotors, a hand expansion valve (pos. 124) is

installed in the main oil injection line.

Variable speed drive (VSD) units running high-pressure applications are equipped with a motor-

ised valve in this line. The motorised valve closes with the rotational speed and ensures that the

amount of oil in the compressor does not get too high when lowering the speed.

Adjustment of the hand expansion valve and the motorised oil injection valve is described in the

operating manual.

Female

Male

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......