Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

110/168

008831 en 2020.10

To check the deflection of the vibration dampers while loaded, measure "A", Fig. 80, while the unit

is still suspended in the crane. After the unit has been installed, measure "A" once more. The dif-

ference (deflection)

must

be between 3 and 5 mm for all vibration dampers.

If this is not the case, insert liner plates under the vibration dampers until the above deflection

has been obtained.

As vibration dampers for marine use should also dampen vibrations coming from the foundation

caused by the main and auxiliary engine, vibration dampers are selected on the basis of an infor-

mation table and the mentioned descriptions. Send the information table, including appendices,

to your local Johnson Controls representative, who will then select the appropriate dampers.

7.24

VSD equipment

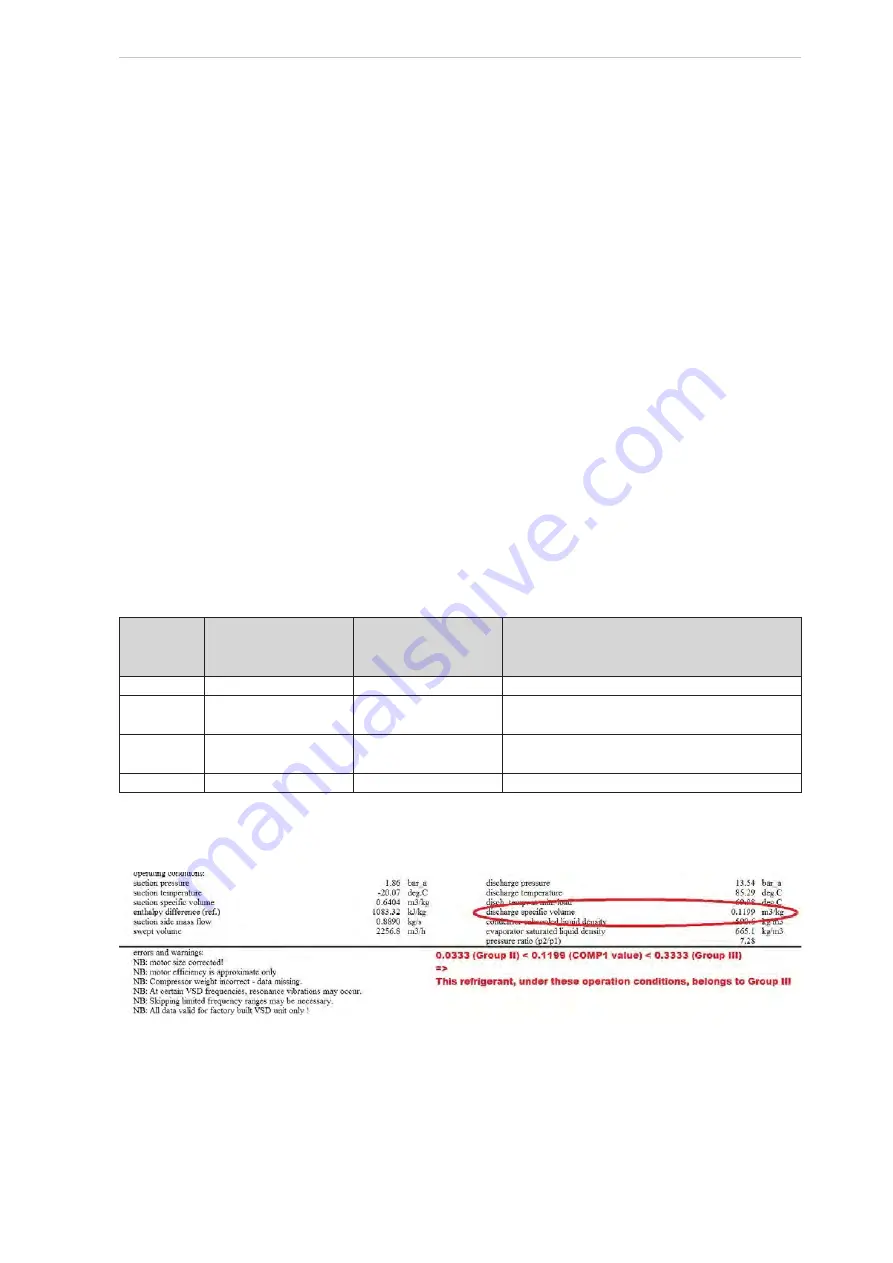

Equipment running variable speed (VSD) is more likely to encounter resonance causing critical vi-

brations. During selection, an assessment of equipment feasibility for variable speed must be car-

ried out, based on the risk chart below. The table values are based on reference temperatures of

35°C of condensation pressure and discharge temperatures at 75°C (60°C for HFCs). Every re-

frigerant belongs to either group I, II, III or IV. Which group is determined by the most severe

property, whether this is density or the speed of sound in the refrigerant at operating conditions.

It is also a prerequisite that the compressor is running close to ideal VI as any over- or under-

compression will increase vibrations significantly.

To ensure that vibrations are handled safely, all Sabroe VSD equipment must be checked during

commissioning using our VibraGuard tool and procedure, or equivalent. It is the commissioning

engineer’s responsibility to document the equivalence.

Group

Specific volume

[m3/kg]

Average speed of

sound in gas

[m/s]

Examples of refrigerants

usually in the group

I

< 0.0167

< 175

R507, R404A, R410A

II

< 0.0333

< 300

R134A, R407(A+C+F), R22, CO

2

(R744),

R32, MR gas

Note 1

III

< 0.3333

< 500

(some exceptions)

Ammonia (R717), Propane (R290)

IV

> 0.3333

> 500

Steam (R718)

Note 1: Even though MR gas is typically in group II, be aware that the possibility of performing

hot work (welding) on site may be limited due to flammability. In such case, variable speed appli-

cations must be avoided.

•

Lower speed of sound enables the gas to resonate in smaller volumes

•

Lower specific volume (larger density) increases the amplitude (severity) of the vibration.

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......