Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

120/168

008831 en 2020.10

7.26

Instruction for mounting of coupling

The arrangement of motor and compressor is mounted stress-free on the unit to ensure sound

operation. The arrangement is pre-aligned from factory. If the motor has not been mounted from

factory or if, for some other reason, either the motor or the compressor has been mounted on

site, the arrangement must be aligned properly by means of shimming and/or adjustment.

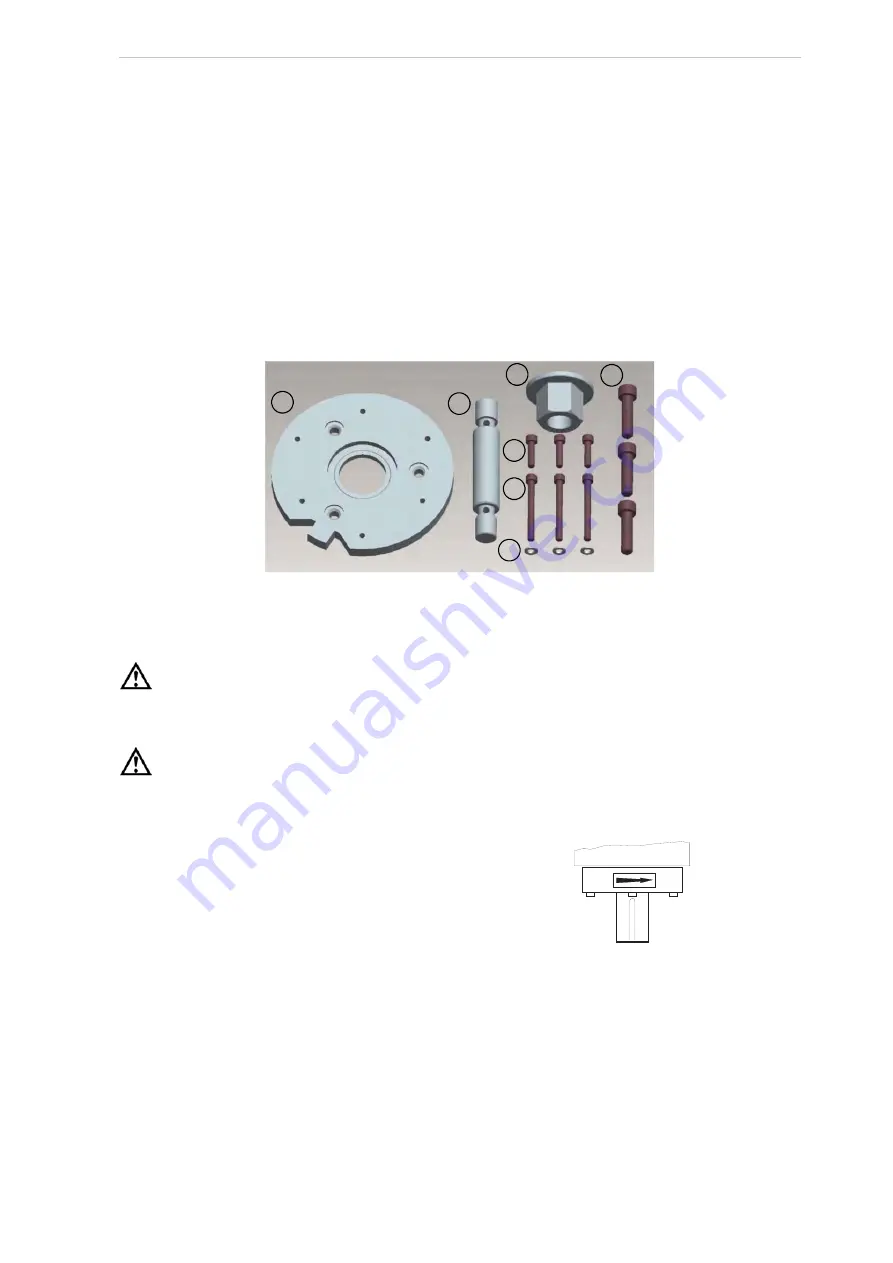

In order to be able to mount and dismantle the coupling, without the risk of damaging any compo-

nents such as the shafts or the coupling parts, a special toolset has been designed. The toolset

(part no. 3083-398) is shown in Fig. 82 and is available from the Johnson Controls Industrial Re-

frigeration Parts Centre in Denmark, if required. The use of the toolset is described in the “Com-

missioning guide, mechanical”.

Fig. 82

Checking motor/compressor rotation

Warning!

Make sure that the coupling hubs are tightened to the shaft before rotating the motor to prevent

them from flying off and possibly causing serious injury or death.

Warning!

Injury may occur if items such as loose clothing become entangled in the spinning motor shaft.

Compressor rotation is clockwise when

facing the end of the compressor shaft.

Under no conditions

should the motor rotation

be checked with the coupling centre installed as

damage to the compressor may result. Bump

the motor to check for correct compressor rota-

tion. After verification, install disc drive spacer

as applicable.

Compressor/motor coupling installation

The unit has compressor to motor alignment through the use of a machined cast iron tunnel. This

tunnel is factory-set through machining tolerances ensuring motor/compressor alignment.

No alignment is required in the field

. See Fig. 83.

5

3

1

2

4

6

7

COMPRESSOR

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......