Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

159/168

15.7

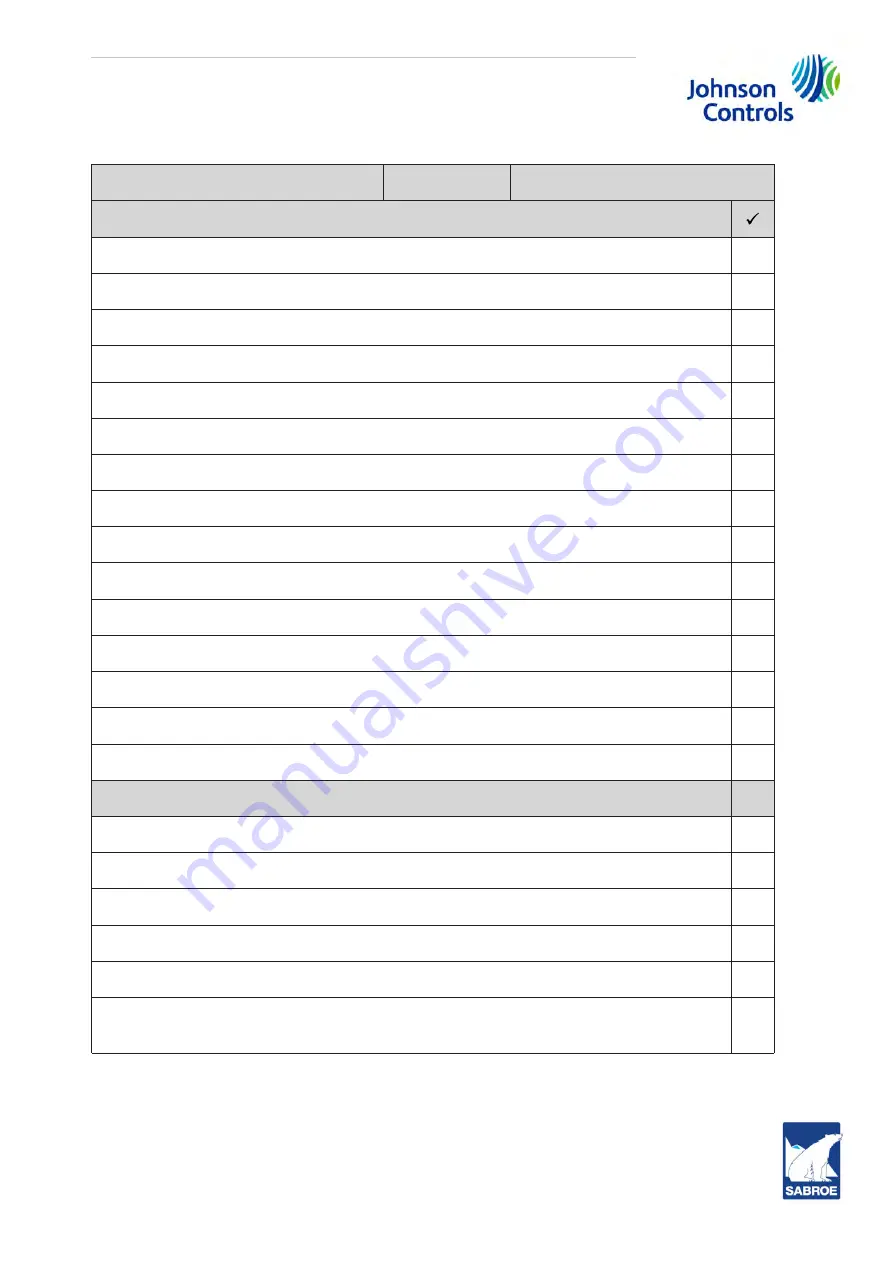

Commissioning checklist

Compressor serial no.:

Date:

Name:

Check before start-up

Read and understand all Sabroe manuals (compressor, UniSAB , chiller, etc.)

Read and understand manuals for third party components (electric motors, valves, etc.)

Check unit installation and vibration damper adjustment

Carry out functional testing of safety equipment

Read the opening pressures on all safety valves, and check that they are correct

Carry out vacuum test

Check UniSAB set-up (see list of settings), and check VSD set-up, as applicable

Check oil level

Check that the heating element in the oil has been on for 6-8 hours before start

Take a sample of the primary refrigerant (must be free from water, air, etc.)

Check that the motor rotation direction is correct

Check that the coupling is aligned

Check that compressor cooling is connected correctly

Check that the plant is not leaking

Check that the valves are in the correct position for operation

Check after start-up

Check that the capacity regulation system is working correctly

Check the refrigerant charge (at full load)

Check the unit for vibrations

Check the unit for vibrations using VibraGuard (variable speed)

Make a start-up log at full load (on the back of this form)

Take out a representative lubricating oil sample after about 1 hour of operation, and save it

for minimum 1 year from commissioning date

Table 58: Commissioning checklist

Summary of Contents for Sabroe SAB 193 L

Page 1: ...SAB 193 233 283 S A frame including ATEX Screw compressor units Engineering manual en ...

Page 2: ......

Page 169: ......