521271-UIM-D-1211

24

Johnson Controls Unitary Products

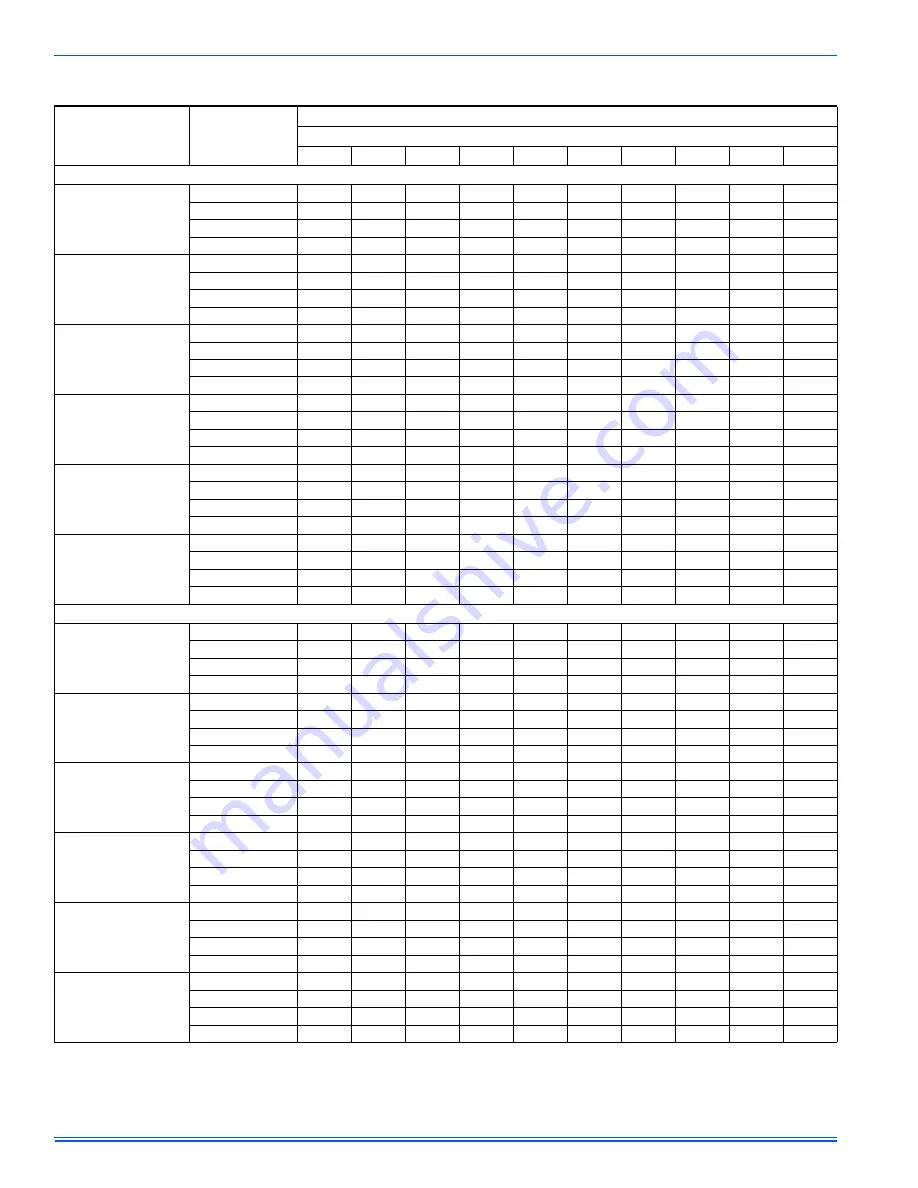

NOTES:

1. Airflow expressed in standard cubic feet per minute (CFM).

2. Motor voltage at 115 V.

3. Airflow through motor side (right side) may be slightly less than the data shown above.

Table 14:

Blower Performance CFM - Any Position - CFM

Models

Speed

Bottom Airflow Data (SCFM)

Ext. Static Pressure (in. H2O)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Bottom Return (without filter)

060A12

High

1358 1341 1319 1303 1275 1238 1190 1130 1062 943

Medium

High 1097 1083 1075 1064 1042 1024 997 962 906 821

Medium

Low 935 928 920 899 872 840 809 771 731 659

Low

800 779 763 736 711 687 657 622 584 529

080B12

High

1329 1307 1285 1247 1195 1143 1091 1027 927 806

Medium

High 994 1004

1008 984 970 941 893 839 773 669

Medium

Low 786 790 782 781 761 743 726 685 630 540

Low

655 654 647 629 620 594 560 524 469 399

080C16

High

1881 1822 1783 1696 1602 1539 1465 1394 1267 1130

Medium

High 1553 1535 1492 1456 1408 1343 1279 1226 1113 1014

Medium

Low 1312 1286 1288 1260 1205 1143 1091 1029 966 841

Low

1169

1166

1128

1098

1069

1032 987 909 835 747

100C16

High

2069 2014 1956 1885 1820 1748 1668 1577 1468 1362

Medium

High 1662 1656 1639 1608 1586 1544 1491 1421 1338 1204

Medium

1368 1371 1377 1376 1367 1334 1295 1250 1188 1104

Low

1016 1014 1018 1030 1012 996 975 944 898 852

100C20

High

2893 2774 2687 2589 2478 2376 2255 2120 1978 1824

Medium

High 2272 2243 2204 2169 2086 2018 1940 1842 1743 1602

Medium

Low 1765 1752 1737 1718 1674 1619 1561 1493 1437 1312

Low

1425 1380 1409 1378 1307 1274 1226 1180 1113 1025

120C20

High

2701 2620 2533 2429 2338 2227 2112 1993 1861 1706

Medium

High 2125 2083 2046 1994 1955 1901 1857 1737 1621 1497

Medium

Low 1664 1664 1647 1619 1580 1555 1468 1392 1332 1226

Low

1358 1339 1330 1318 1286 1235 1185 1141 1060 938

Left Side Return (without filter)

060A12

High

1406 1401 1394 1379 1338 1304 1261 1202 1135 1040

Medium

High 1129 1126 1107 1094 1076 1047 1010 966 921 843

Medium

Low 970 947 933 916 890 863 827 789 741 668

Low

834 809 797 768 740 710 677 634 586 534

080B12

High

1274 1285 1255 1239 1207 1158 1111 1049 979 830

Medium

High 975 974 968 960 948 923 879 823 756 672

Medium

Low 777 771 772 762 752 734 695 651 604 529

Low

647 634 623 610 602 588 552 506 457 381

080C16

High

1825 1781 1746 1695 1641 1587 1521 1429 1330 1184

Medium

High 1516 1493 1482 1464 1442 1411 1343 1275 1192 1035

Medium

1294 1297 1271 1238 1187 1120 1083 1028 979 851

Low

1126 1115

1095

1049

1027 996 957 929 840 742

100C16

High

2009 1994 1933 1893 1836 1763 1691 1606 1508 1389

Medium

High 1523 1506 1521 1490 1466 1435 1393 1326 1241 1119

Medium

Low 1230 1249 1245 1230 1218 1195 1161 1120 1039 949

Low

1126 1115

1095

1049

1027 996 957 929 840 742

100C20

High

2964 2886 2794 2707 2623 2522 2415 2281 2149 2012

Medium

High 2192 2178 2150 2109 2098 2007 1956 1888 1795 1671

Medium

Low 1699 1695 1706 1632 1612 1568 1519 1460 1392 1293

Low

1361 1356 1337 1304 1267 1243 1191 1149 1077 994

120C20

High

2828 2768 2699 2612 2524 2423 2308 2219 2118 1982

Medium

High 2085 2073 2042 2029 1967 1896 1893 1816 1717 1635

Medium

Low 1620 1631 1636 1593 1567 1557 1520 1476 1407 1263

Low

1322 1311 1302 1271 1241 1201 1162 1101 1042 979