697936-UIM-B-01211

Johnson Controls Unitary Products

15

ACCESSORY CONNECTIONS

The furnace control will allow power-switching control of various acces-

sories.

ELECTRONIC AIR CLEANER CONNECTION

Two 1/4” (6.4 mm) spade terminals (EAC and NEUTRAL) for electronic

air cleaner connections are located on the control board. The terminals

provide 115 VAC (1.0 amp maximum) during circulating blower opera-

tion.

HUMIDIFIER CONNECTION

Two 1/4” (6.4 mm) spade terminals (HUM and NEUTRAL) for humidifier

connections are located on the control board. The terminals provide 115

VAC (1.0 amp maximum) during heating system operation.

A mounting hole is provided on the control panel next to the furnace

control board for mounting a humidifier transformer if required.

TWINNING

These furnaces are not to be twinned. If more than one furnace is

needed in an application, each furnace must have its own complete

duct system and its own wall thermostat.

SECTION VI: CONDENSATE PIPING AND

FURNACE VENTING CONFIGURATION

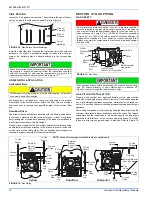

CONDENSATE DRAIN LOCATION

As shipped from the factory:

• For all 040, 060 & 080K input furnaces the main drain is plumbed

through the casing right-side opening when viewed from the front

of the furnace.

• For all 100 & 120 input furnaces the main drain is plumbed through

the casing left-side opening when viewed from the front of the fur-

nace.

The condensate hoses must slope downwards at all points.

When drain hose routing changes are required (shown in Figures 22-

25), be sure to cap all un-used openings.

If rerouting hoses - excess length should be cut off so that no sagging

loops will collect and hold condensate - which will cause the furnace to

not operate.

No hose clamps are needed for connecting to the condensate pan.

The condensate will flow to the drain better if an open stand pipe is

installed in the drain line. See Figure 20.

If evaporator coil or humidifier drains are combined with the furnace

drain, then the open stand pipe could be raised higher, above the 5”

minimum.

The Figures 22 - 25 show the condensate drain arrangement for the

various possible furnace and vent blower positions.

The furnace condensate pan is self priming and contains an internal

trap to prevent flue gas leaking. Do not install an external condensate

trap.

The furnace, evaporator coil, and humidifier drains may be combined

and drained together. The evaporator coil drain may have an exter-

nal, field-supplied trap prior to the furnace drain connection to prevent

conditioned air leakage. All drain connections (furnace, evaporator

coil, or humidifier) must be terminated into an open or vented drain as

close to the respective equipment as possible. Regular maintenance

is required on condensate drainage system.

NOTICE

Condensate must be disposed of properly. Follow local plumbing

or wastewater codes. The drain line must maintain a 1/4" per foot (20

mm/m) downward slope to the drain.

If an external vent tee is being installed, then it must have its own

condensate trap before it is disposed into an open or vented drain.

This is not to be considered as a second trap as referenced else-

where in this document.

FIGURE 20:

Typical. Condensate drain, vertical installation

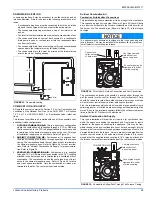

A loop has been added to the pressure switch vacuum hose. How-

ever, ensure that all pressure switch hoses are routed such that they

prevent any condensate from entering the pressure switch.

It is possible for condensation to form inside the combustion air

(intake) pipe in the summer months if significant length of combustion

air pipe passes through conditioned space. This problem can be

averted by the addition of a simple drain tee, or a drain tee with a

drain on the combustion air pipe as close to the furnace as possible,

as shown in Figure 21. This is true for all long horizontal venting in

any furnace configuration. This will prevent the condensate from

entering the furnace.

To Open Or

Vented Drain

Tee

5” Min.

Open Stand Pipe

(Anti-siphon air vent)

NOTICE