2

VA-8122 Proportional Valve Actuator Product/Technical Bulletin

O

peration

The actuator uses a reversible synchronous motor to

accurately position the valve. The motor can reliably

generate 22 pounds of force in either the Drive Down

(DD) or Drive Up (DU) direction.

Once the valve closes, a shutoff force builds up. When

this force reaches 22 pounds, a lever within the

actuator operates a force sensor that stops the motor.

The constant load at the end of travel ensures tight

valve seat shutoff and compensates for seat wear.

Field calibration of shutoff is not required. The actuator

maintains the shutoff force and its last position even if

power is removed.

Note:

The valve stem can be positioned manually by

turning the manual adjustment knob shown in

Figure 2. Rotating the knob counterclockwise

moves the valve stem up.

Yoke/

Machine Screw

Lever

Plate

Drive

Screw

Jumpers

W1-W5

AUTOCAL

Pushbutton

Spade

Terminals (3)

LED

Circuit Board

+

2

4

C

O

M

V

D

C

/m

A

Stem Retainer/

Position Indicator

Manual

Adjustment

Knob

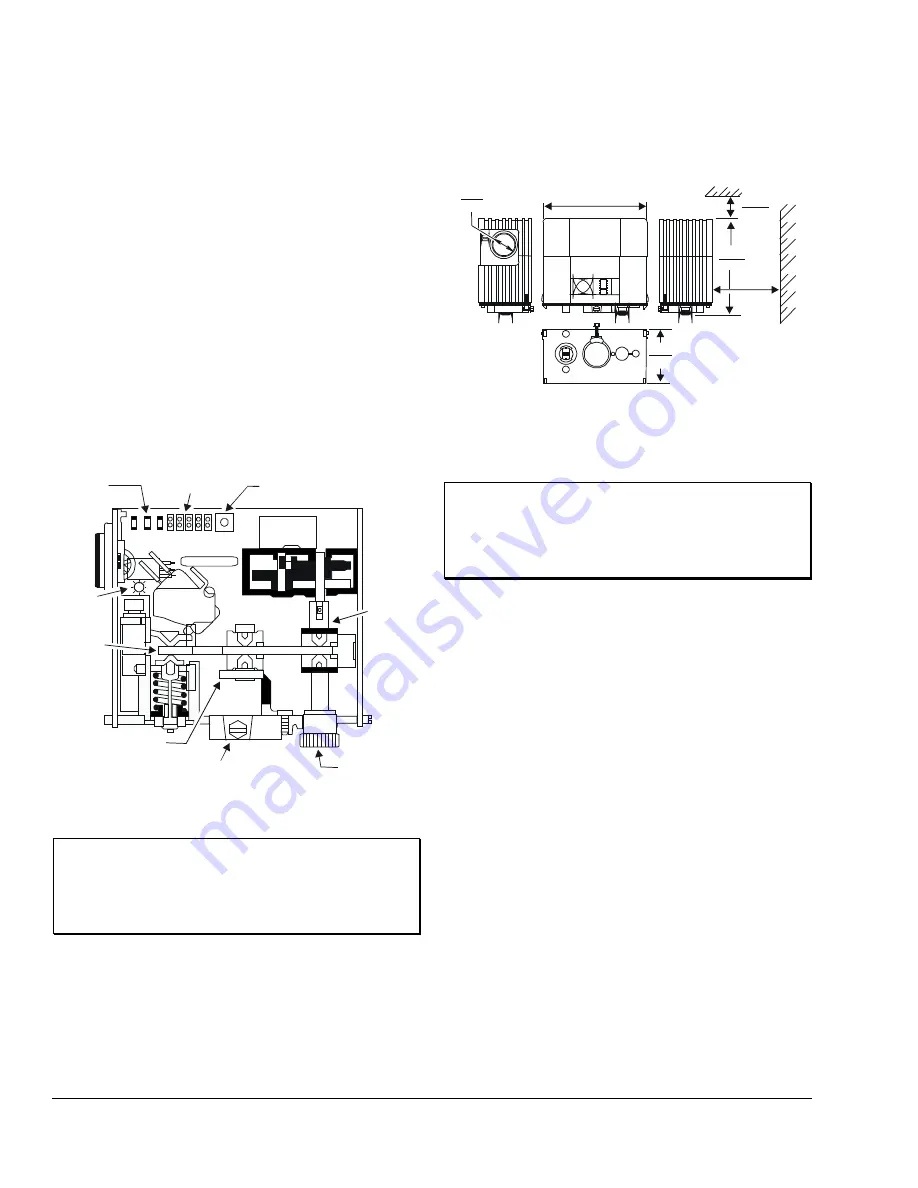

Figure 2: VA-8122 Components

IMPORTANT:

There are no internal mechanical

stops in the actuator. Never drive

the actuator unless it is installed on

the proper valve body, or the

actuator may be damaged.

D

imensions

See Figure 3 for actuator dimensions.

5.00

127.0

2.50

63.5

0.87

22.2

4.50

114.3

0.50*

12.7

2.50*

63.5

* Required for cover

removal clearance.

Figure 3: VA-8122 Dimensions, in. (mm)

I

nstallation

IMPORTANT:

Dripping water must be prevented

from entering the actuator housing,

since this could damage the

actuator. Do not cover the actuator

with thermal insulating material.

Note:

The VA-8020-100 kit (ordered separately) is

required if mounting to a VT Series Terminal

Unit Valve.

Kit Includes

•

VA-8122 actuator

•

VA-8020-605 stem retainer and clip kit

Tools Required

•

5/16 in. (8 mm) nut driver or 3/16 in. (5 mm)

flat-blade screwdriver

•

needle-nose pliers

•

crescent wrench (to fit 1-1/4 in. bonnet

adaptor nut)