VA-8122 Proportional Valve Actuator Product/Technical Bulletin

3

M

ounting

IMPORTANT:

Do not use on valves having a

stroke over 5/16 in. Travel beyond

5/16 in. will damage the actuator or

prevent complete shutoff.

Note:

In horizontal piping applications, it is

recommended that the valve be mounted

within 85° of the upright position. When

mounted in vertical piping, the valve must be

protected from moisture.

Unpack the actuator and proceed as follows:

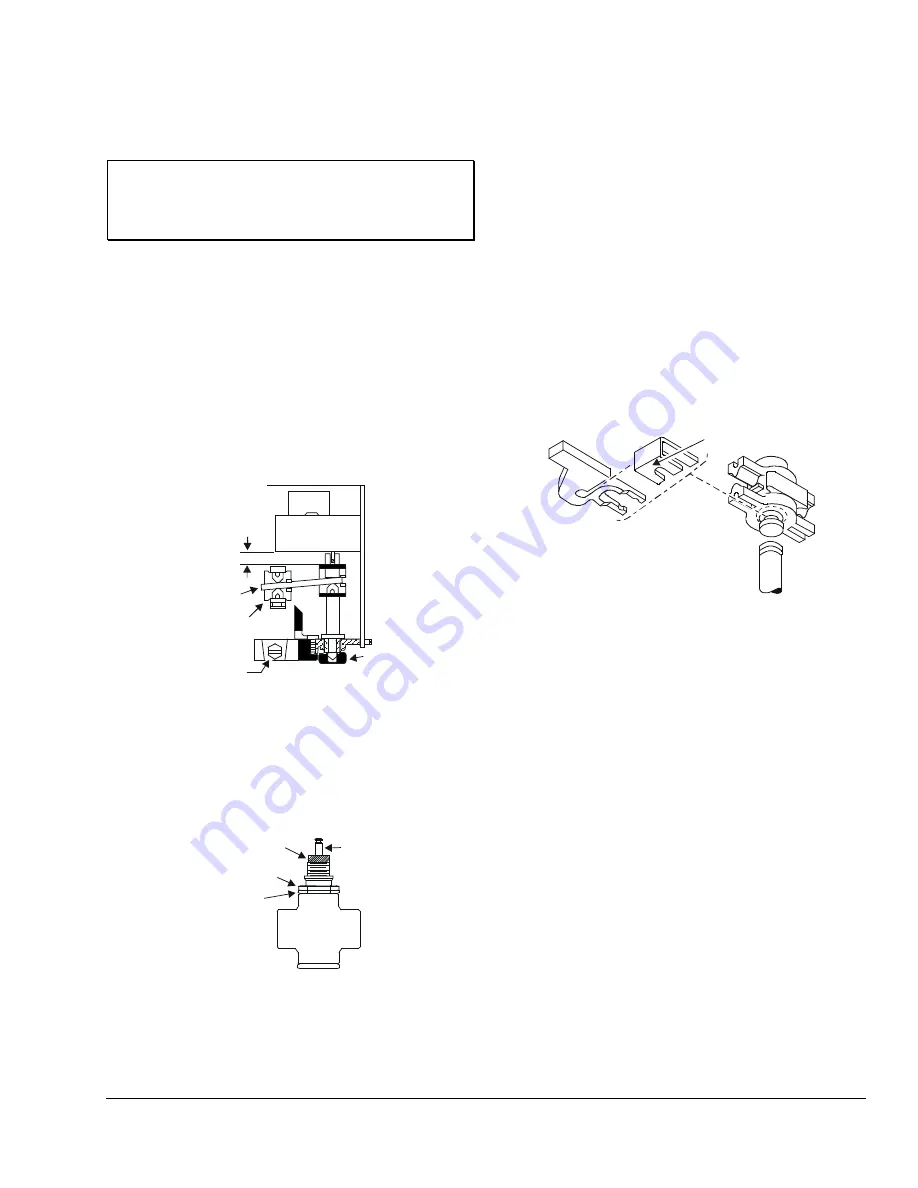

1. Remove the actuator cover by pressing inward on

the plastic tabs while sliding the cover up and

forward.

2. Make sure that the lever plate is within 1/4 in.

(6.4 mm) of the upper stop. (See Figure 4.)

Lever Plate

Approximately

1/4 in.

Coupler

Yoke/

Machine Screw

Manual

Adjustment

Knob

Figure 4: Plate Position

3. For VT valves, thread the bonnet adaptor nut

(included in the VA-8020-100 kit) onto the

valve bonnet shown in Figure 5, and tighten with a

wrench until it is snug.

Bonnet

Adaptor Nut

Packing

Nut

Valve

Bonnet

Stem

Figure 5: Valve Bonnet Adaptor

4. Position the actuator yoke on the bonnet adaptor

nut, making sure the yoke is flush with the surface

of the nut.

Note:

If the valve stem is touching the coupler and

preventing a flush contact, use the manual

adjustment knob (shown in Figure 4) to

reposition the coupler.

5. Secure the actuator to the valve bonnet by

tightening the hex-head machine screw provided.

6. Place the stem retainer and coupling clip over the

valve stem, so the lower (shorter) portion of the

coupling clip is positioned in the locking groove on

the valve stem as shown in Figure 6.

Valve Stem

Coupler

Coupling Clip

Stem

Retainer

Lower Portion

of Clip

Figure 6: VA-8020-605 Stem Retainer and Clip Kit

Note:

The extended portion of the stem retainer

must be located on the right so that it lines up

in the window of the cover. It may be

necessary to pull the valve stem up to meet

the coupler or to rotate the manual adjustment

knob (shown in Figure 4) clockwise to run the

coupler down.

7. Push the white plastic stem retainer until the

coupling clip moves forward into the groove, and

the retainer locks the clip in place.

8. Verify that the valve stem is located at the back of

the groove by examining the connection.

To remove the coupling clip, use pliers to grip the stem

retainer and pull outward. (See Figure 6.)