JOHNSON CONTROLS

136

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

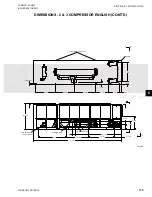

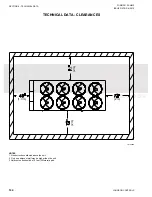

SECTION 6 - TECHNICAL DATA

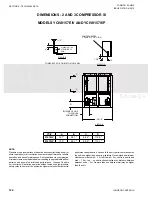

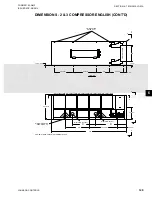

NOTE:

Placement on a level surface of free of obstructions (including snow, for

winter operation) or air circulation ensures rated performance, reliable

operation, and ease of maintenance. Site restrictions may compromise

minimum clearances indicated below, resulting in unpredictable airflow

patterns and possible diminished performance. Johnson Controls

unit controls will optimize operation without nuisance high-pressure

safety cutouts; however, the system designer must consider potential

performance degradation. Access to the unit control center assumes

the unit is no higher than on spring isolators. Recommended minimum

clearances: side to wall – 2m; rear to wall – 2m; control panel to end

wall – 1.2m; top – no obstructions whatsoever; distance between

adjacent units – 3m. No more than one adjacent wall may be higher

than the unit.

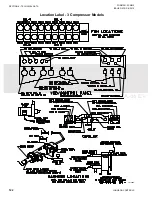

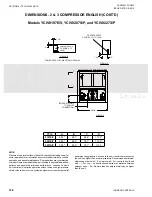

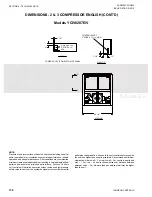

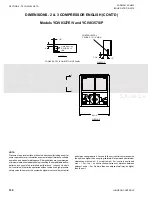

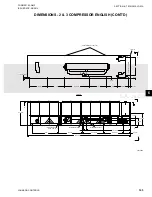

Models YCIV0287E/V

VIEW C-C

VIEW B-B

12"

CONTROL ENTRY

3" WIDE X 13 1/2" HIGH

1 1/2"

4"

POWER ENTRY

10" WIDE X 13" HIGH

1 3/4"

POWER ENTRY IS ON BOTTOM OF PANEL

88 1/8"

VIEW A-A

C

C

B

B

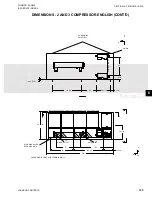

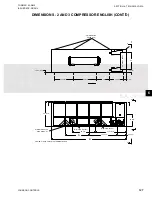

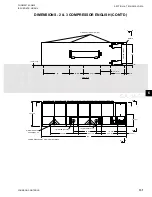

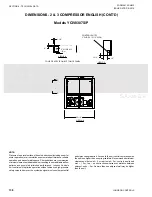

DIMENSIONS - 2 & 3 COMPRESSOR ENGLISH (CONT'D)

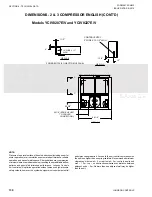

POWER ENTRY

10" WIDE X 13"

HIGH

Summary of Contents for YCIV0157

Page 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...